Geopolymer used for marine concrete outer protective layer and preparation method thereof

A marine concrete and external protection technology, which is applied in cement production and other directions, can solve the problems of difficult construction, high cost of waterproof layer, poor waterproof performance, etc., and achieve the effects of cost saving, cost reduction, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

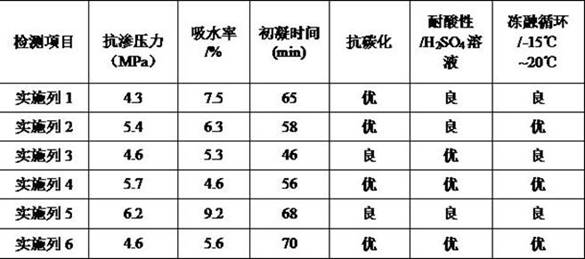

Examples

Embodiment 1

[0024] In this example, 33 parts of slag and 49 parts of quartz sand weighed are poured into the mixer, stirred at a slow speed for 100 seconds to obtain a mixture, and then 0.01 part of water reducer and 0.02 part of defoamer are added to 10 parts of compound alkali Fully stir in the excitation solution, then use 300W power to ultrasonically oscillate for 0.5 hours to obtain a mixed solution, then add 0.01 parts of acid-treated multi-walled carbon nanotubes to the above mixed solution, and use 300W power to ultrasonically oscillate for 0.5 hours to obtain acidified carbon nanotubes. tube mixed solution, and finally the acidified carbon nanotube mixed solution was added to the mixture and stirred for 150 seconds, then poured, vibrated, and cured under standard curing conditions for 28 days to obtain the slag-based polymer used for the outer protective layer of marine concrete .

Embodiment 2

[0026] In this example, 33 parts of slag and 49 parts of quartz sand weighed are poured into the mixer, stirred at a slow speed for 100 seconds to obtain a mixture, and then 0.01 part of water reducer and 0.02 part of defoamer are added to 10 parts of compound alkali Fully stir in the excitation solution, then use 300W power to ultrasonically oscillate for 0.6 hours to obtain a mixed solution, then add 0.01 parts of acid-treated multi-walled carbon nanotubes to the above mixed solution, and use 300W power to ultrasonically oscillate for 0.6 hours to obtain acidified carbon nanotubes. tube mixed solution, and finally the acidified carbon nanotube mixed solution was added to the mixture and stirred for 150 seconds, then poured, vibrated, and cured under standard curing conditions for 28 days to obtain the slag-based polymer used for the outer protective layer of marine concrete .

Embodiment 3

[0028] In this example, 36 parts of slag and 46 parts of quartz sand weighed are poured into the mixer, stirred at a slow speed for 100 seconds to obtain a mixture, and then 0.02 parts of water reducer and 0.01 part of defoamer are added to 10 parts of compound alkali Fully stir in the excitation solution, then use 300W power to ultrasonically oscillate for 0.5 hours to obtain a mixed solution, then add 0.01 parts of acid-treated multi-walled carbon nanotubes to the above mixed solution, and use 300W power to ultrasonically oscillate for 0.5 hours to obtain acidified carbon nanotubes. tube mixed solution, and finally the acidified carbon nanotube mixed solution was added to the mixture and stirred for 150 seconds, then poured, vibrated, and cured under standard curing conditions for 28 days to obtain the slag-based polymer used for the outer protective layer of marine concrete .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com