Adsorption process method

A process method and adsorbent technology, applied in the field of petrochemical gas adsorption and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment 1 is the process of purifying hydrogen by SMR shift gas. SMR conversion gas flow is 15000Nm 3 / h, the shift gas component content is shown in Table 1.

[0048] Table 1 Composition of shift gas

[0049]

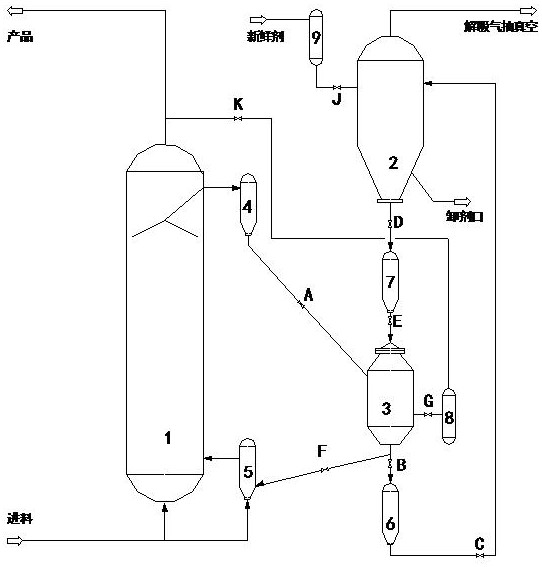

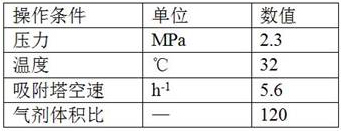

[0050] The adsorption process in this embodiment consists of an adsorption tower, a regeneration tower and a lock hopper circulation system. The adsorption tower is filled with CO 2 , CO special adsorbent. The operating conditions of the adsorption tower are shown in Table 2.

[0051] Table 2 Operating conditions of adsorption tower

[0052]

[0053] The SMR shift gas enters the adsorption tower from bottom to top, and the bed layer of the adsorption tower is in a fluidized state, fully contacting with the feed gas. CO in the feed gas 2 , CO is adsorbed, and the adsorption process is as described in the specific embodiment. After adsorption by this process, the gas composition at the outlet of the adsorption tower is shown in Table 3. Outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com