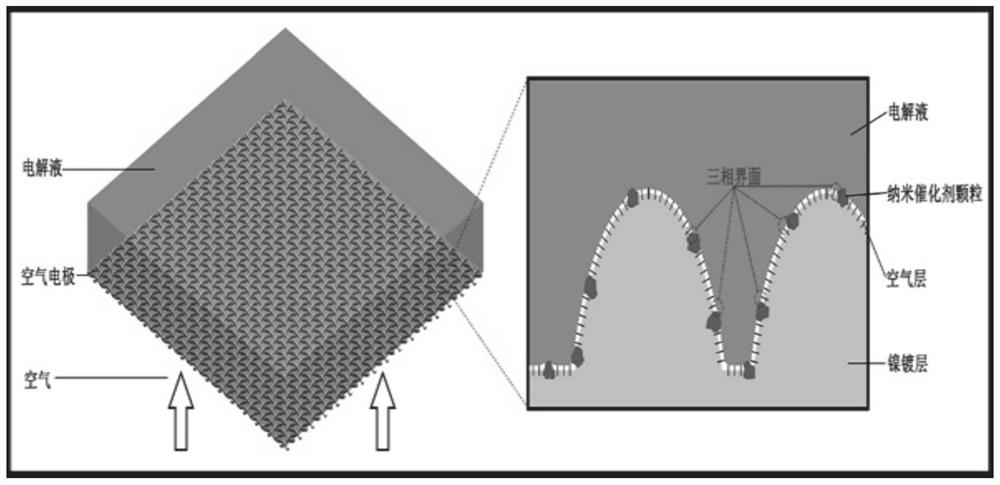

Air electrode of super-hydrophobic metal-air battery as well as preparation method and application

An air battery and air electrode technology, which is applied to battery electrodes, fuel cell half-cells, primary battery-type half-cells, circuits, etc., can solve the cumbersome preparation process of super-hydrophobic batteries, poor super-hydrophobic performance, and unsuitable large-scale applications. mass production etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In one or some embodiments of the present disclosure, a method for preparing the air electrode of the above-mentioned superhydrophobic metal-air battery is provided, including the following steps:

[0037] Prepare composite plating solution: first add nickel salt and acidic solution into ultrapure water, mix and dissolve until the solution turns green, use a pH regulator to adjust the pH of the solution, and weigh a certain amount of surfactant and transition metal oxide nanoparticles , add the mixed solution in turn under strong stirring, stir and ultrasonically disperse evenly;

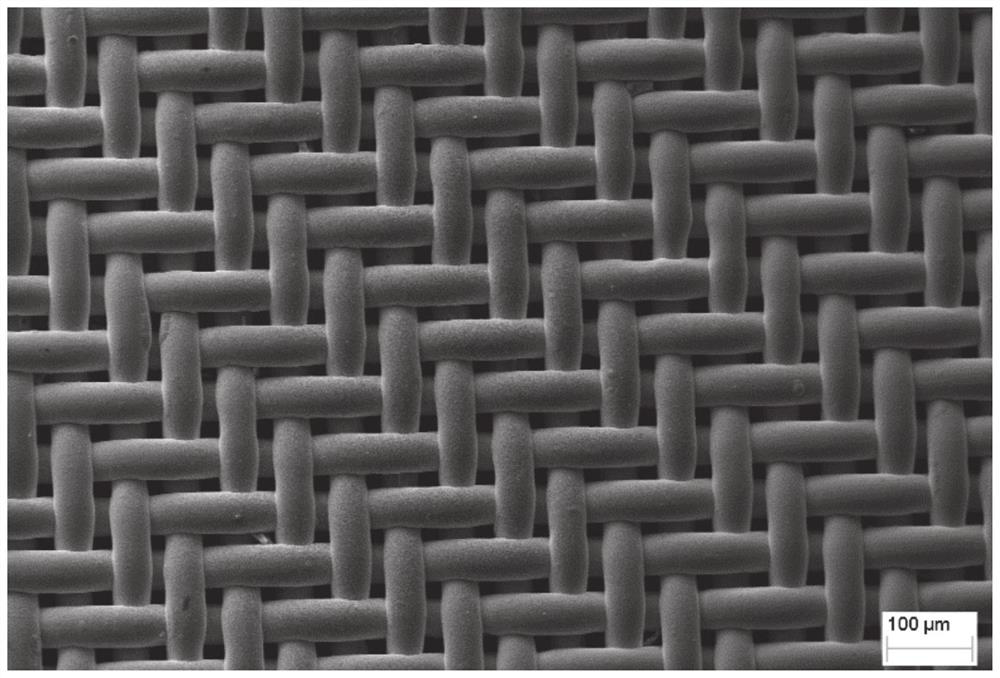

[0038] Electrode pre-treatment: take stainless steel mesh, soak to remove oil and rust in turn; take pure nickel sheet, mechanically polish, clean and activate;

[0039] Composite plating: use stainless steel mesh as the cathode and nickel sheet as the anode, perform composite plating under magnetic stirring, and keep the plating solution for a period of time;

[0040] Post-processing: After...

Embodiment 1

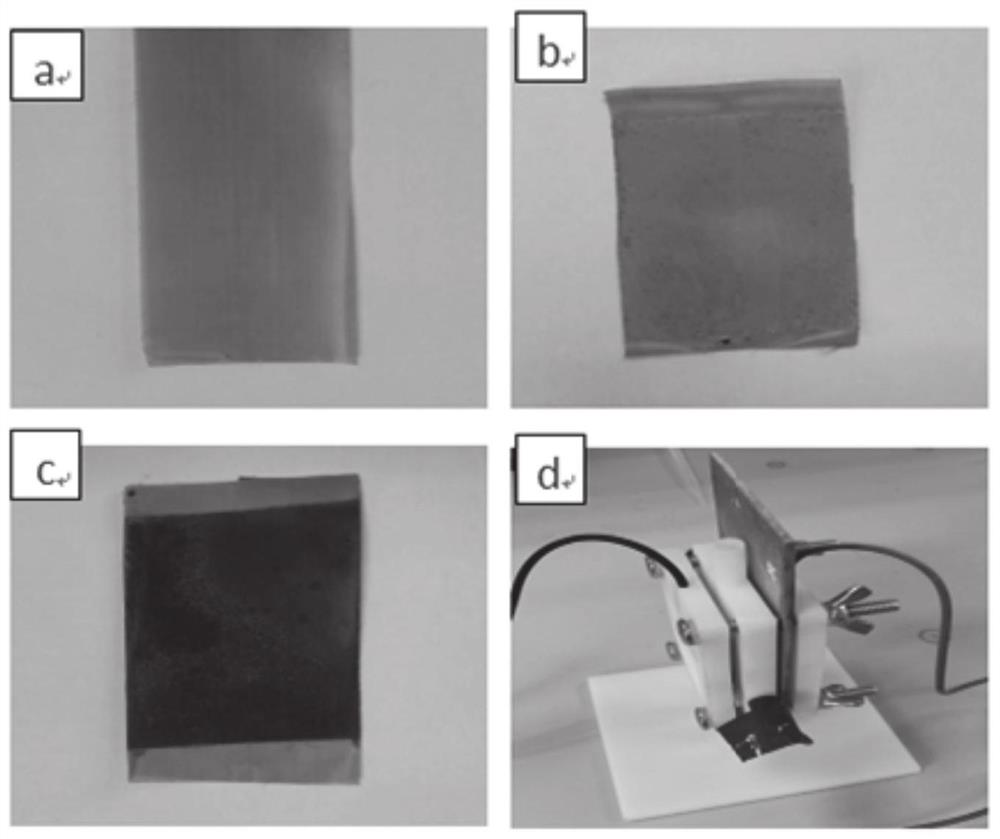

[0064] The present embodiment provides a kind of preparation method of the air electrode of superhydrophobic metal-air battery, comprises the steps:

[0065] 1) Prepare composite plating solution: first add nickel sulfate, nickel chloride, and boric acid into ultrapure water, dissolve under magnetic stirring conditions at 40°C until the solution turns green, and use hydrochloric acid or sodium hydroxide to adjust the pH of the solution to 4-5 . Weigh 0.05g / L cetyltrimethylammonium bromide, 5g / Lα-MnO 2 Nanoparticles were added to the above green solution sequentially under strong stirring, stirred and dispersed evenly by ultrasonic.

[0066] 2) Electrode pre-treatment: Take 400 mesh stainless steel mesh, immerse it in acetone, sodium hydroxide solution, hydrochloric acid solution in order to remove oil and rust; take pure nickel sheet, use SiC sandpaper, from high to low, from 120# in order Mechanically polish to 1200#, clean with deionized water, and activate with 1mol / L hyd...

Embodiment 2

[0072] The present embodiment provides a kind of preparation method of the air electrode of superhydrophobic metal-air battery, comprises the steps:

[0073] 1) Prepare composite plating solution: first add nickel sulfate, nickel chloride, and boric acid into ultrapure water, dissolve under magnetic stirring conditions at 40°C until the solution turns green, and use hydrochloric acid or sodium hydroxide to adjust the pH of the solution to 4-5 . Weigh 0.1g / L cetyltrimethylammonium bromide, 10g / Lα-MnO 2 Nanoparticles were added to the above green solution sequentially under strong stirring, stirred and dispersed evenly by ultrasonic.

[0074] 2) Electrode pre-treatment: Take 400 mesh stainless steel mesh, immerse it in acetone, sodium hydroxide solution, hydrochloric acid solution in order to remove oil and rust; take pure nickel sheet, use SiC sandpaper, from high to low, from 120# in order Mechanically polish to 1200#, clean with deionized water, and activate with 1mol / L hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com