Glass tube heat exchanger capable of preventing dust accumulation and blockage and application thereof

A glass tube, anti-fouling technology, applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of reduced heat exchange efficiency, dust and crystalline salt adhesion, etc., and achieve strong corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

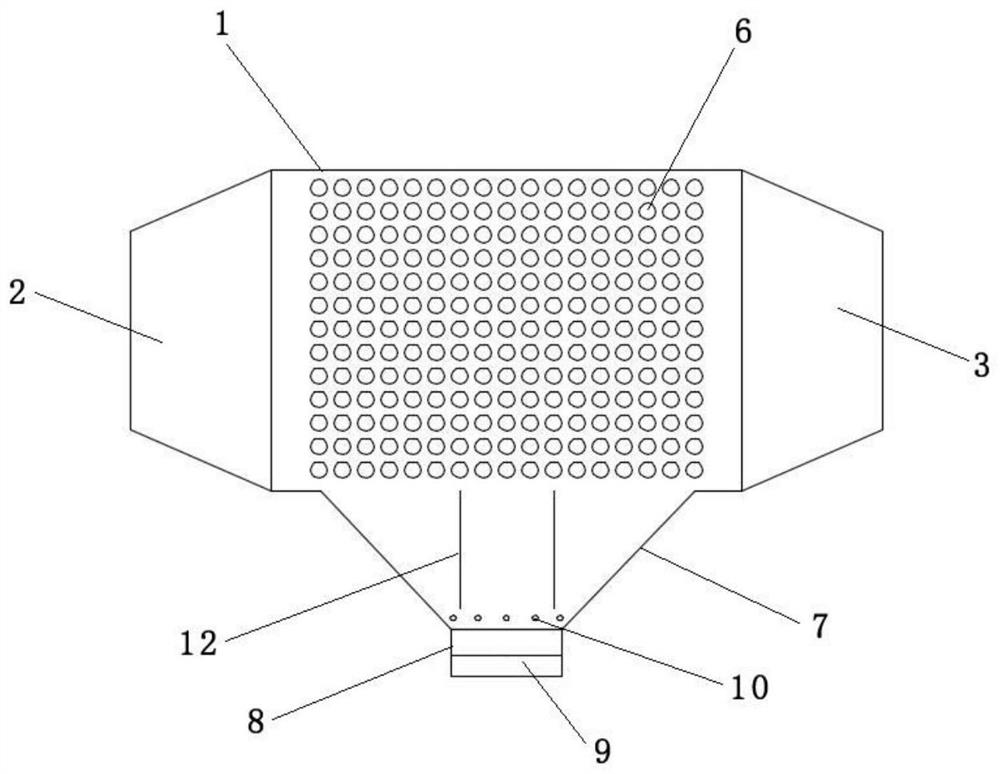

[0034] Such as Figure 1-3 As shown, a glass tube heat exchanger for preventing fouling from clogging includes a shell 1 . The shell 1 is respectively provided with flue gas inlet and outlet 2, 3 and air inlet and outlet 4, 5, and the shell 1 is provided with a heat exchange tube 6, the material of the heat exchange tube 6 is quartz glass, and the two ends of the heat exchange tube 6 Connect with air inlet and outlet 4 and 5 respectively. Both the heat exchange tube 6 and the flue gas flow channel are arranged horizontally. The lower part of the shell 1 is provided with an ash collection hopper 7, and the ash discharge port 8 at the lower end of the ash collection hopper 7 is provided with an ash discharge valve 9. There is a purge pipe 10, and one end of the purge pipe 10 protrudes from the ash collecting hopper 7 to connect with the air source. Scan hole 11.

[0035] The heat exchange tubes in the glass heat exchange tube assembly are arranged in a square, and the distanc...

Embodiment 2

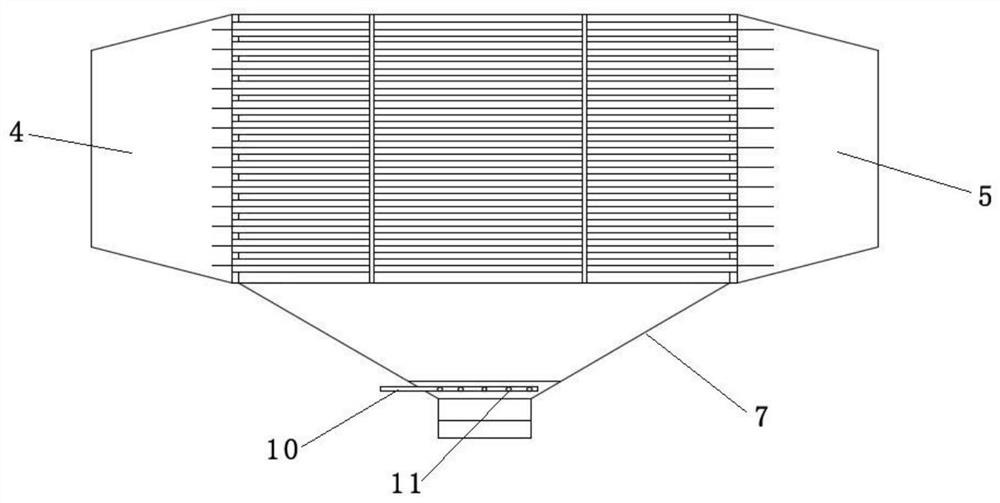

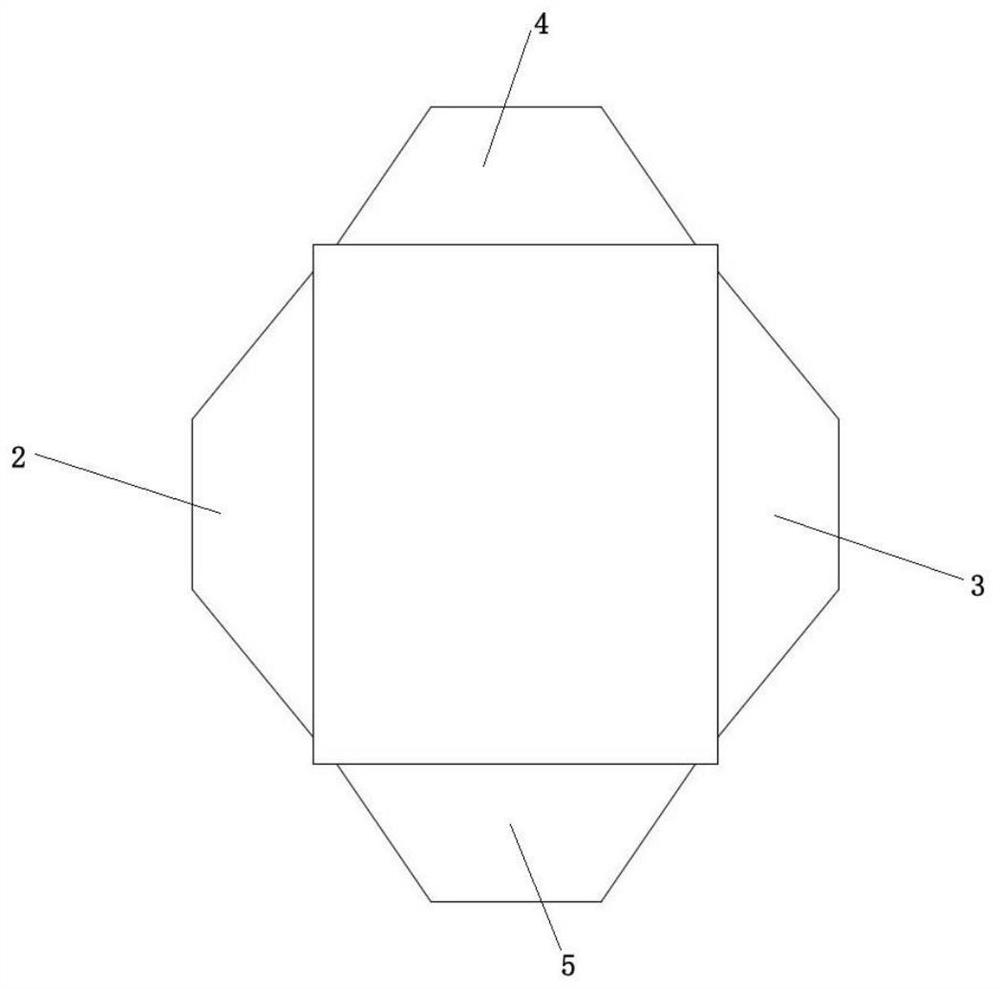

[0040] Such as Figure 4 and 5As shown, a glass tube heat exchanger for preventing fouling from clogging includes a shell 1 . The shell 1 is respectively provided with flue gas inlet and outlet 2, 3 and air inlet and outlet 4, 5, and the shell 1 is provided with a heat exchange tube 6, the material of the heat exchange tube 6 is high borosilicate glass, and the heat exchange tube 6 The two ends communicate with the air inlet and outlet 4 and 5 respectively. The heat exchange tubes 6 are arranged horizontally, the flue gas flow channel is L-shaped, the flue gas inlet 2 is located on the side wall of the ash collecting hopper 7 , and the flue gas outlet 3 is located on the upper end surface of the shell 1 . The lower part of the housing 1 is provided with an ash collecting hopper 7, and the ash discharge port 8 at the lower end of the ash collecting hopper 7 is provided with an ash discharge valve 9, and the ash collecting hopper 7 is provided with a purge pipe 10, and one end...

Embodiment 3

[0042] Such as Figure 6 As shown, a glass tube heat exchanger for preventing fouling from clogging includes a shell 1 . The shell 1 is respectively provided with flue gas inlet and outlet 2, 3 and air inlet and outlet 4, 5, and the shell 1 is provided with a heat exchange tube 6, the material of the heat exchange tube 6 is quartz glass, and the two ends of the heat exchange tube 6 Connect with air inlet and outlet 4 and 5 respectively. The heat exchange tubes 6 are U-shaped or snake-shaped, the air inlets and outlets 4 and 5 are arranged on the upper surface of the shell 1, and the flue gas flow channels are arranged horizontally. The lower part of the housing 1 is provided with an ash collecting hopper 7, and the ash discharge port 8 at the lower end of the ash collecting hopper 7 is provided with an ash discharge valve 9, and the ash collecting hopper 7 is provided with a purge pipe 10, and one end of the purge pipe 10 protrudes from the collection The ash hopper 7 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com