Method for exploiting oil and gas products in underground thin and medium-thickness oil shale ore bed through pyrolysis

An oil shale and underground heat technology, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of ineffective utilization of heat in the ore seam and high design cost of the middle wellbore, so as to reduce the production cost and save solids. The effect of high well cost and energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

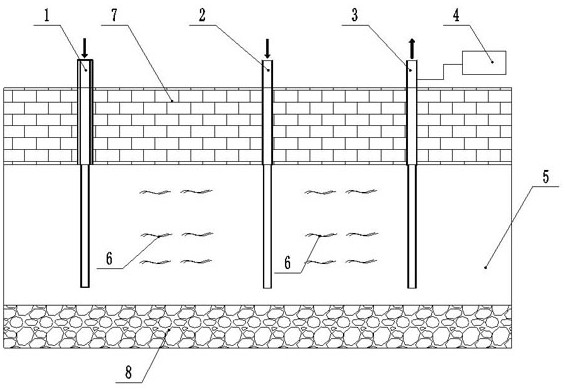

[0038] When the thickness of the oil shale deposit is 5m and the buried depth is 100m, the concrete steps of the method for exploiting oil and gas products from the underground pyrolysis thin oil shale deposit are as follows:

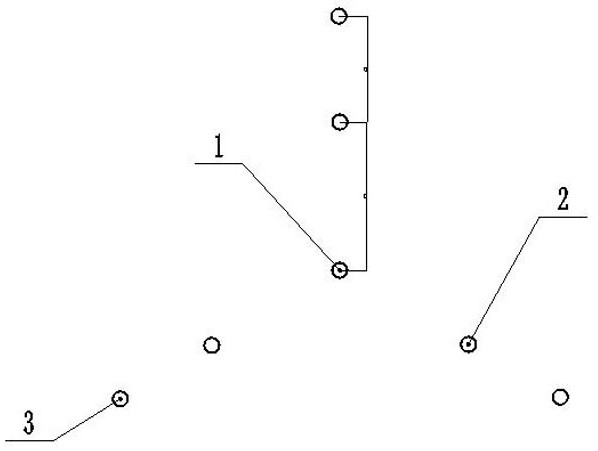

[0039] 1. Drill wells in the target area selected by the oil shale mine. The well layout is "Y-shaped", and the middle well 1, the middle circle well 2 and the peripheral well 3 are formed in sequence from the inside to the outside, and a total of 7 wells are arranged. , the well spacing between the middle well 1 and the middle well 2 is 70m, and the well spacing between the middle well 2 and the peripheral well 3 is 50m;

[0040] 2. Lower the well pipes in each drilling hole. The lowering position of the well pipes should be close to the bottom of the shale layer 5 to be pyrolyzed. Among them, the middle well 1 uses a double-layer well pipe structure, and heat insulation should be carried out between the double-layer well pipes. treatment, so as to red...

Embodiment 2

[0047] When the thickness of the oil shale deposit is 15m and the buried depth is 200m, the specific steps of the method for exploiting oil and gas products from the underground pyrolysis medium-thick oil shale deposit are as follows:

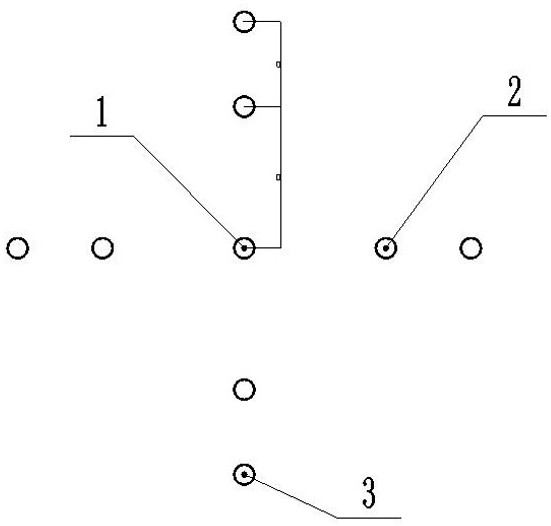

[0048] 1. Drill wells in the selected target area of the oil shale mine. The layout of the wells is "cross-line", and the middle well 1, the middle well 2 and the peripheral well 3 are formed in sequence from the inside to the outside, and a total of 9 wells are arranged. Wells, the well spacing between the middle well 1 and the middle well 2 is 50m, and the well spacing between the middle well 2 and the peripheral well 3 is 30m;

[0049] 2. Lower the well pipes in each drilling hole. The lowering position of the well pipes should be close to the bottom of the shale layer 5 to be pyrolyzed. Among them, the middle well 1 uses a double-layer well pipe structure, and heat insulation should be carried out between the double-layer well pipes. trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com