Non-floating bead low-density cement mortar

A non-floating bead low, cement slurry technology, applied in the field of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

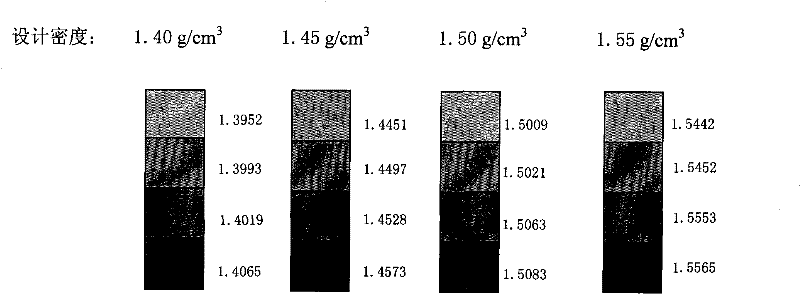

Image

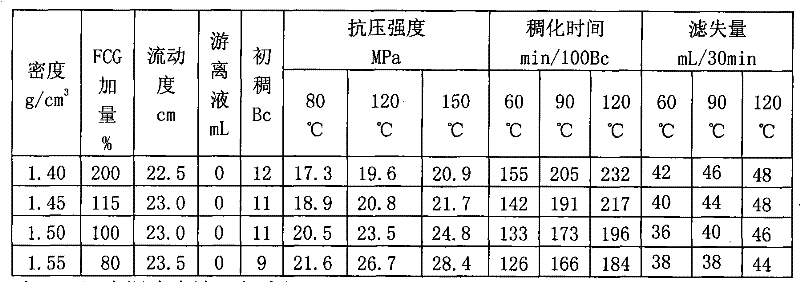

Examples

Embodiment 1

[0014] Embodiment 1: The components and proportioning of the non-bleaching low-density cement slurry are as follows in parts by weight: 100 parts of cement, 321 parts of water, 121 parts of fly ash, 36 parts of silica fume, 36 parts of superfine cement, early strength agent 10 parts, according to the above ratio, mix the external admixture fly ash, silica fume, ultra-fine cement, early strength agent and cement according to the required ratio, and mix it with an appropriate amount of water evenly. The strength of the prepared cement slurry measured at 80°C is 15.4MPa.

Embodiment 2

[0015] Embodiment 2: The non-floating pearl low-density cement slurry components and proportioning are as follows by weight: 100 parts of cement, 321 parts of water, 136 parts of fly ash, 36 parts of silica fume, 36 parts of superfine cement, early strength agent 10 parts were uniformly mixed as in Example 1, and the strength of the prepared cement slurry measured at 80°C was 15.8 MPa.

Embodiment 3

[0016] Embodiment 3: The non-floating pearl low-density cement slurry components and proportioning are as follows by weight: 100 parts of cement, 321 parts of water, 129 parts of fly ash, 33 parts of silica fume, 36 parts of superfine cement, early strength agent 10 parts were uniformly mixed as in Example 1, and the strength of the prepared cement slurry measured at 80° C. was 15.2 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com