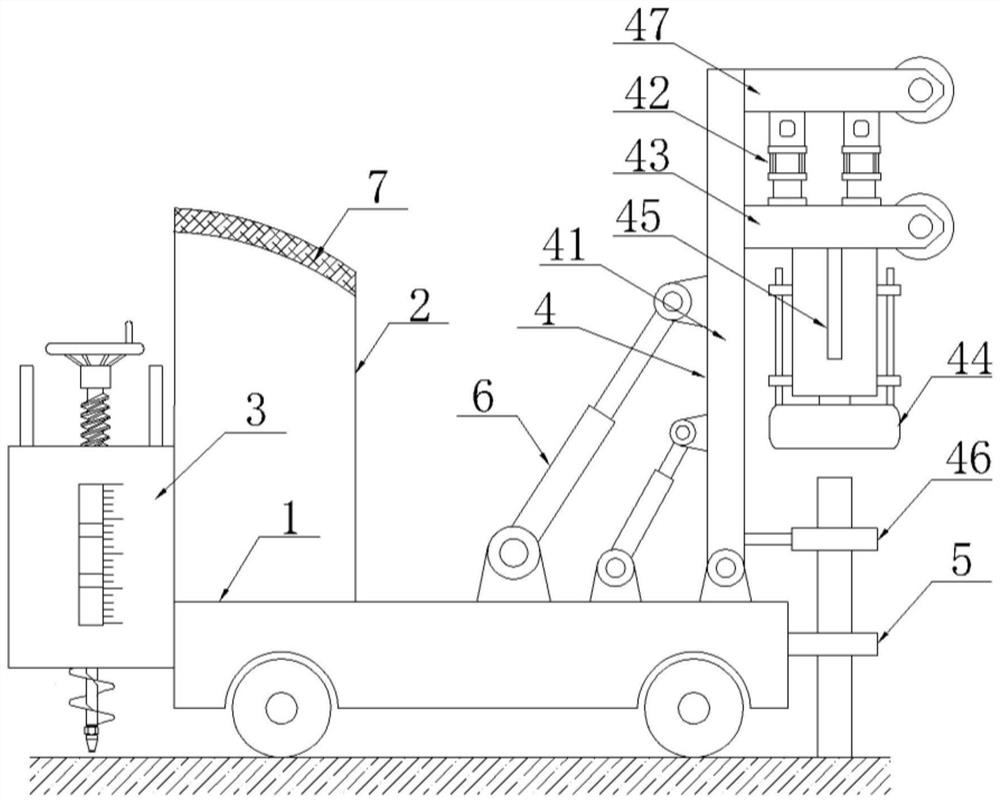

Vertical pile driver with pre-digging function for mounting highway protective fence

A technology for highways and guardrails, which can be used in road safety devices, earth movers/shovels, mechanically driven excavators/dredgers, etc., and can solve problems such as low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

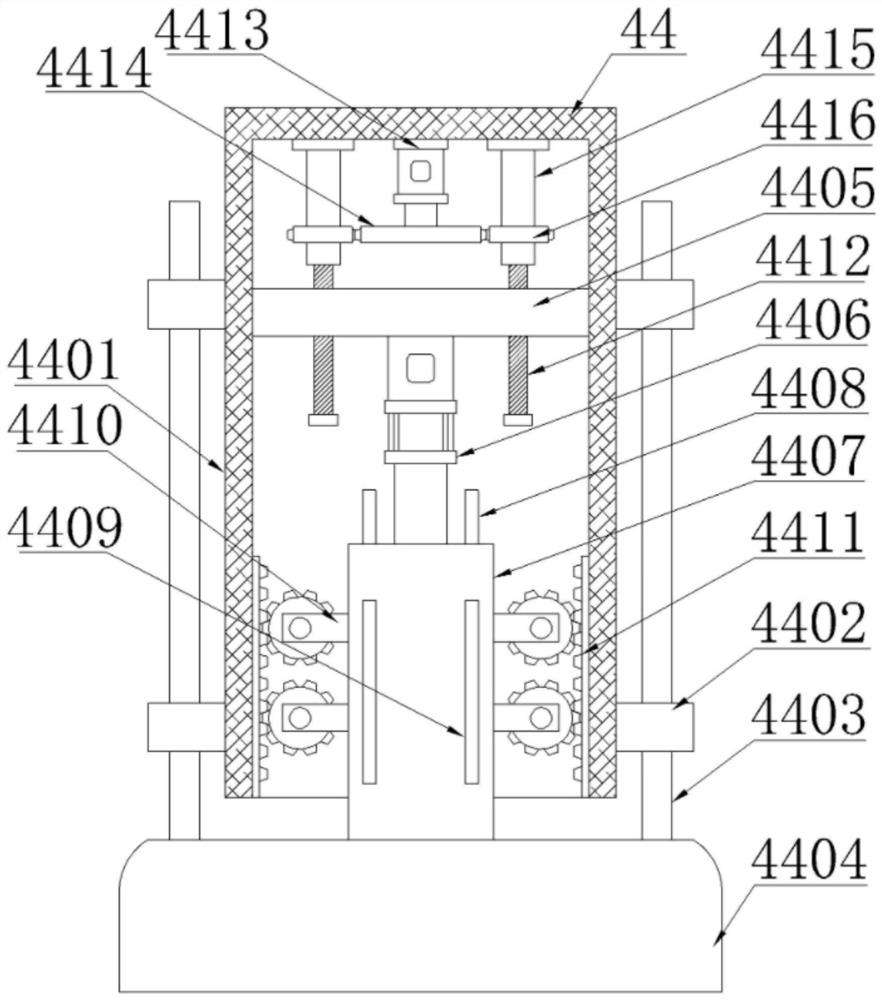

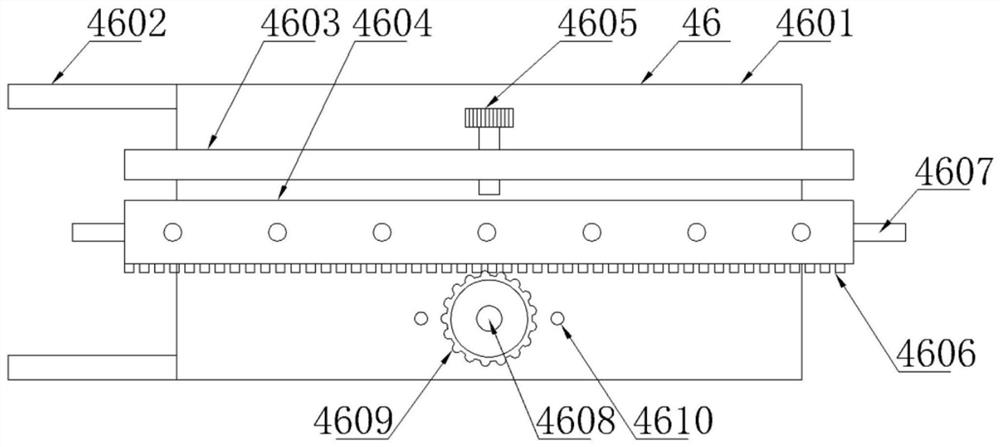

[0028] 1. Pre-excavation work before piling: When adjusting the depth of the excavation, turn the threaded rod 302 to drive the lifting frame 309 to move up and down, change the initial height of the spiral cutter 316, thereby changing the depth of the excavation, and complete the adjustment Finally, screw in the bolt 305 to fix the rotating disk 303 and the threaded rod 302, then start the driving motor 310 and the rotating motor 315, the driving motor 310 drives the transmission gear 312 and the rotating shaft 307 to rotate, and the rotating shaft 307 drives the cam 311 to rotate, and the convex surface of the cam 311 When turning to the bottom, the arc-shaped top block 313 will be pressed down. At this time, the support spring 318 is squeezed. When the convex surface leaves the bottom, the support spring 318 can drive the arc-shaped top block 313 to rise and reset. The shape cutter 316 is driven to slide up and down, and the rotating motor 315 drives the helical cutter 316 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com