Measuring mechanism for light lens processing

A lens processing and measurement mechanism technology, applied in the direction of mechanical thickness measurement, conveyor objects, transportation and packaging, etc., can solve the problems that the thickness of the lens cannot be fully grasped, it is difficult to improve the quality control, and the lens inspection cannot be achieved, so as to ensure the assembly line, Improve efficiency and ensure continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

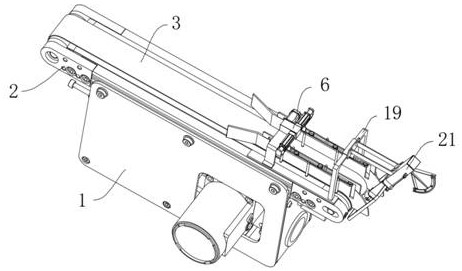

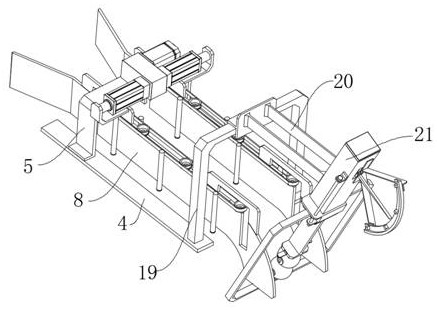

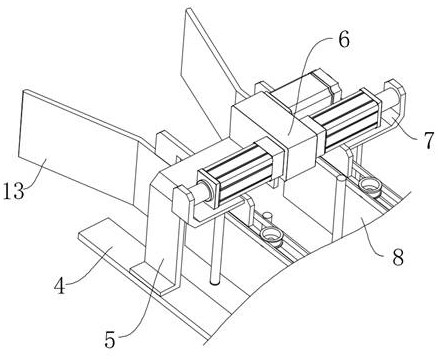

[0033] like Figure 1-Figure 13 The shown measuring mechanism for optical lens processing includes a base 1, a frame 2 fixedly mounted on the upper end of the base 1, a conveyor belt 3 movably arranged on the outer surface of the frame 2, and the upper surface of the conveyor belt 3 passes through a bidirectional telescopic mechanism. Two symmetrical guide plates 8 are provided, the front end of the guide plate 8 extends out of an arc-shaped plate 18 adapted to the front end of the conveyor belt 3, and two sides of each guide plate 8 are synchronously driven by a synchronous wheel mechanism. And keep only the lower end of the toggle lever 16 on the side of the guide plate 8 in contact with the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com