Automatic drainage system for water seepage accident

A technology for drainage systems and accidents, which is applied in the field of automatic drainage systems for water seepage accidents. It can solve the problems of difficult drainage of drainage grooves in time and hidden dangers, and achieve the effects of reducing waste of water resources, enhancing stability, and facilitating cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

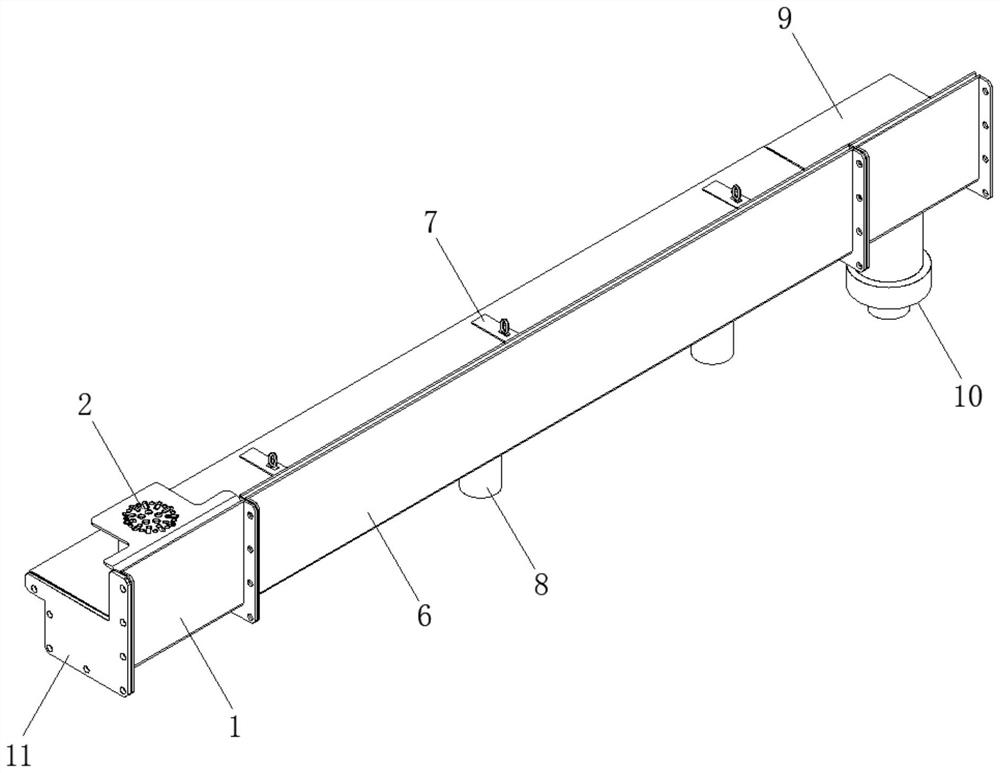

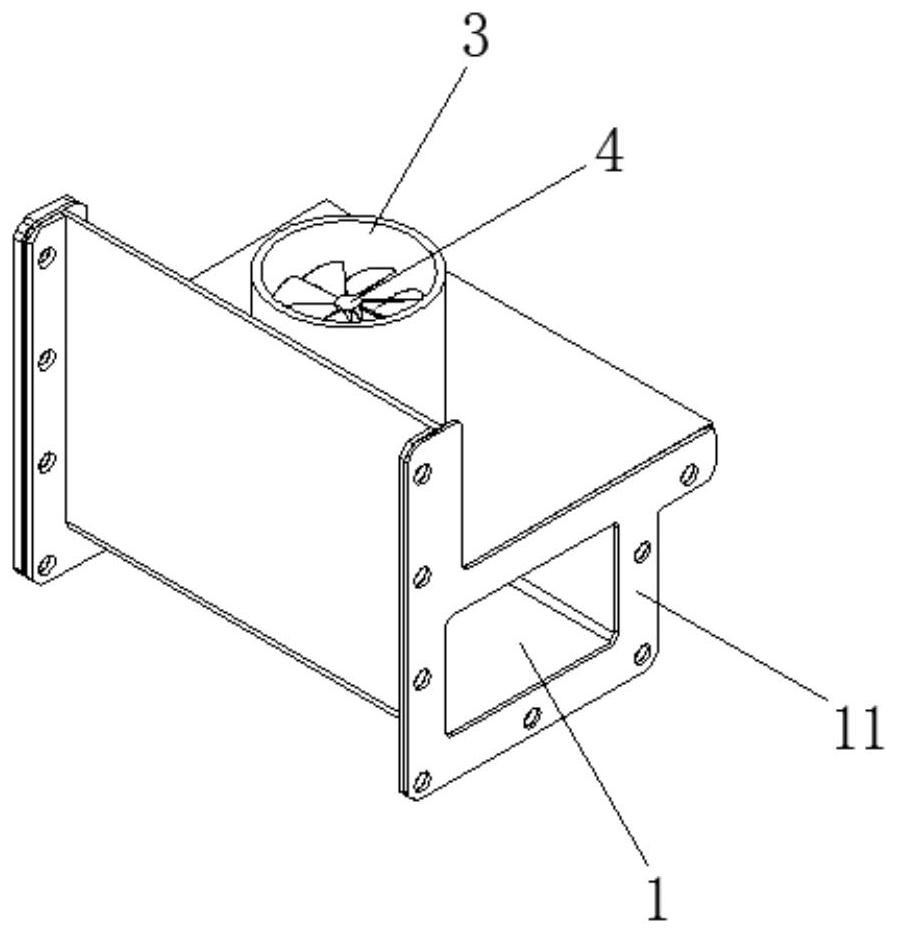

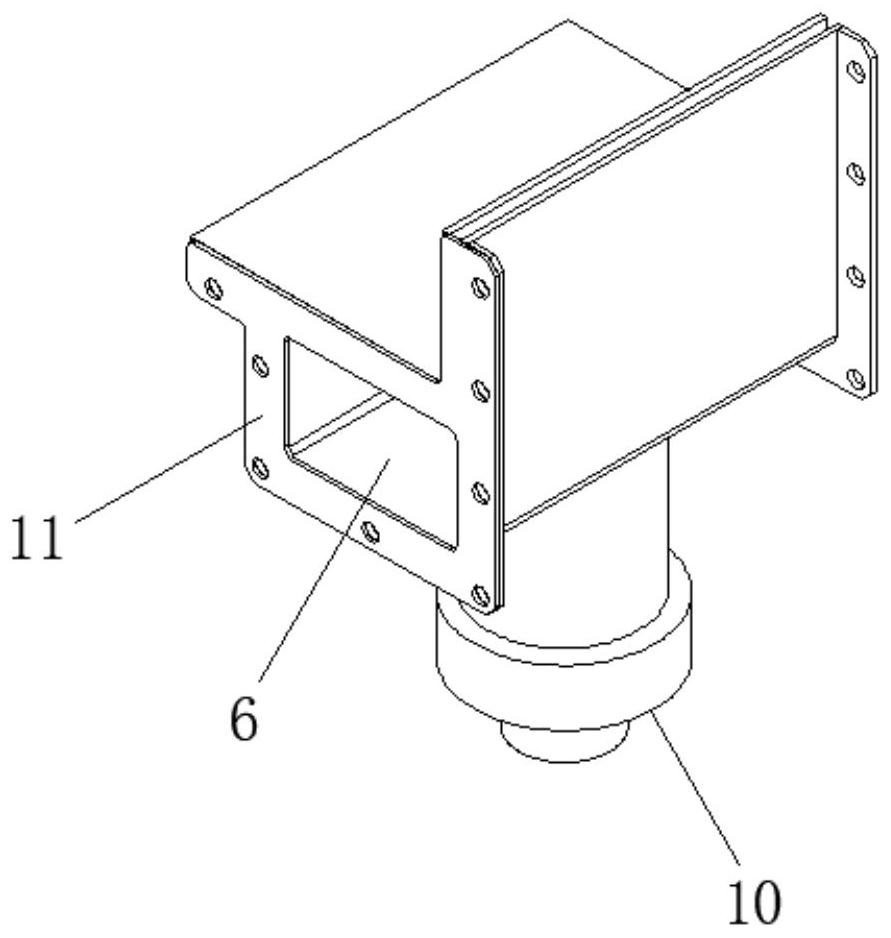

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Please refer to Figure 1-7 , the embodiment of the present invention is as follows:

[0031] An automatic drainage system for water seepage accidents, in figure 1 with Figure 4~7 Middle: including end flow pipe 1, middle flow pipe 6 and final flow pipe 9, floor drain cover 2 is arranged directly above end flow pipe 1, and the side wall of floor drain cover 2 is in sliding contact with the side wall of end flow pipe 1 A water inlet pipe 3 is installed at the bottom of the floor drain cover 2, and the bottom end of the water inlet pipe 3 runs through and extends to the inside of the end flow pipe 1, and the top of the end flow pipe 1 on both sides of the water inlet pipe 3 is provided with a lifting mechanism 5, and The lifting mechanism 5 all includes a tube base 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com