Iron-chromium-aluminum alloy manufacturing process

An iron-chromium-aluminum alloy, manufacturing process technology, applied in metal processing equipment, grain processing, transportation and packaging, etc., can solve problems such as unsatisfactory quality and environmental protection, problematic processing methods, unstable processing quality, etc., and achieve improvement The overall quality is stable, the heating and calcination is fast, and the calcination is thorough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

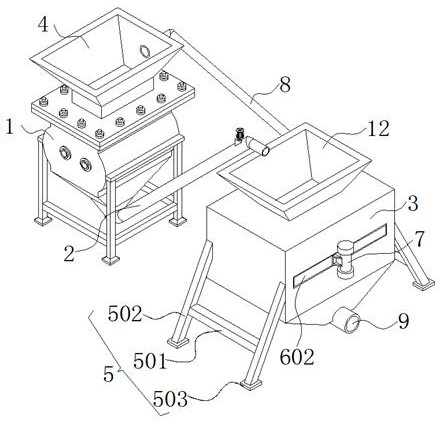

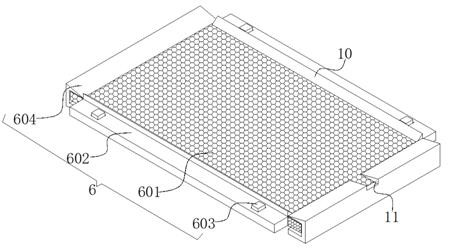

[0034] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0035] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

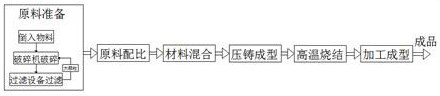

[0036] Such as Figure 1 to Figure 4 As shown, an iron-chromium-aluminum alloy manufacturing process provided in an embodiment of the present invention includes the following steps:

[0037] a. Raw material preparation: first crush and filter the corresponding required materials through the crushing and filtering equipment;

[0038] b. Raw material ratio: Prepare raw materials according to a certain ratio;

[0039] c. Material mixing: Mix various raw materials through a mixer;

[0040] d. Die-casting molding: put the mixed material into the die-casting mold, and die-cast the material through the die-casting machine;

[0041] e. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com