Oily material suitable for producing needle coke as well as preparation method and system thereof

A needle coke and oil quality technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as loss of aromatics, difficulty in needle coke products, and impact on the quality of needle coke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

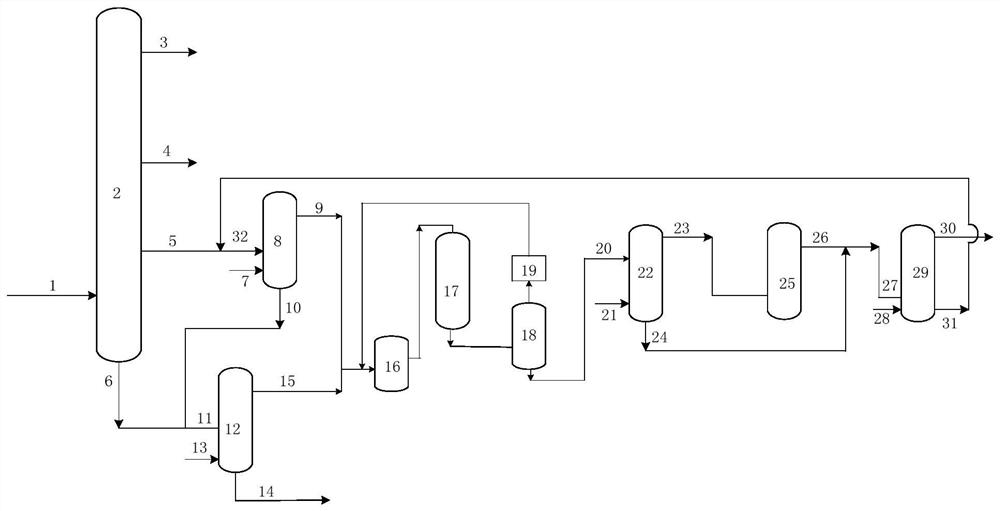

[0026] The first aspect of the present invention provides a method for preparing an oily material suitable for producing needle coke, the method comprising:

[0027] 1) Send the raw oil 1 to the fractionation tower 2 for fractionation treatment to obtain the crude wax oil component 5 and the fractionation tower bottom heavy oil component 6;

[0028] 2) The crude wax oil component 5 and the first steam 7 are sent to the first stripper 8 for the first stripping treatment to obtain the first stripper light component 9 and the first stripper bottom oil 10;

[0029] 3) The fractionation tower bottom heavy oil component 6, the first stripper bottom oil 10 and the second steam 13 are sent to the second stripper 12 to carry out the second stripping treatment, to obtain the second stripper light Component 15 and second stripper bottoms 14;

[0030] 4) sending the light components 9 of the first stripper and the light components 15 of the second stripper to a hydrogenation unit for hy...

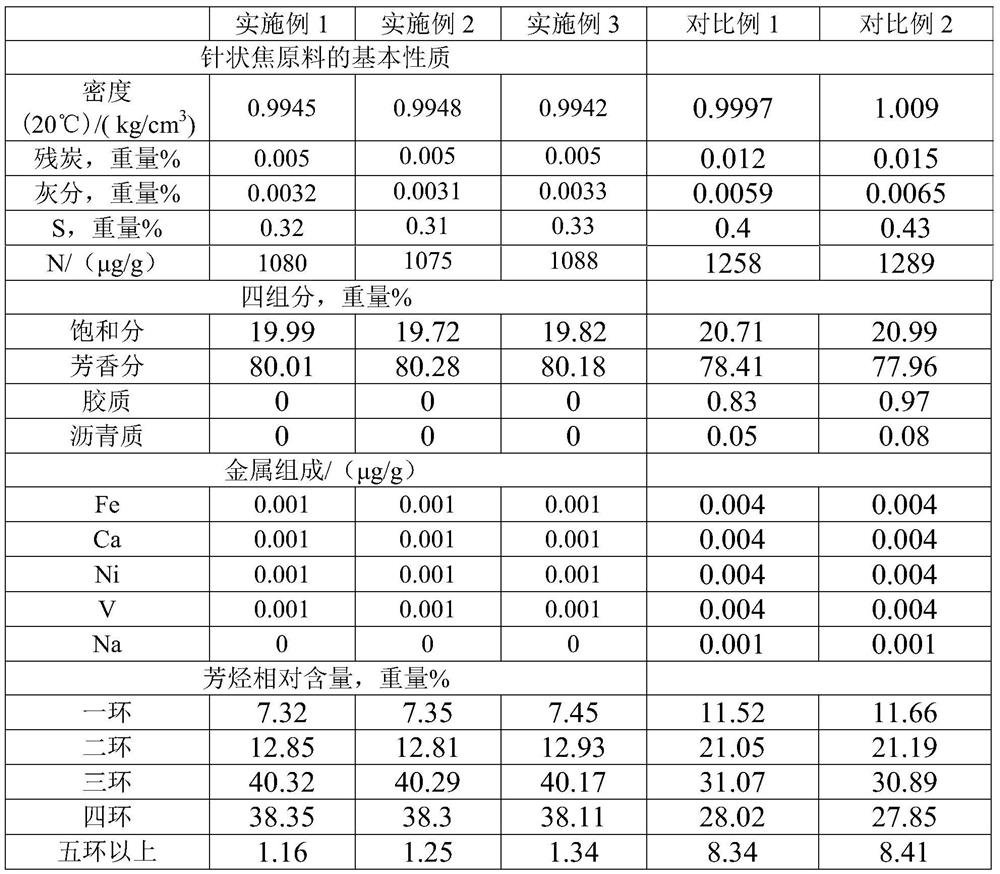

Embodiment 1

[0090] This example is used to illustrate the preparation method of the oily material suitable for producing needle coke according to the present invention.

[0091] use figure 1 The system shown performs the manufacturing process described below.

[0092] (1) Feedstock oil 1 is sent in fractionating tower 2, and fractionating condition is: fractionating tower tower top temperature is 115 ℃, and fractionating tower tower top pressure is 0.12MPa, and fractionating tower tower bottom temperature is 350 ℃ to carry out fractionation treatment, and Separate and obtain gasoline 3, diesel oil 4, crude wax oil component 5 (that is, distillate oil with a distillation range of 350-450° C.) and fractionation tower bottom heavy oil component 6;

[0093] (2) The fourth stripper bottom oil 31 that the crude wax oil component 5 is discharged from the bottom of the fourth stripper 29 is combined to obtain mixed oil 32 and sent to the first stripper 8 to be mixed with the first stripper that ...

Embodiment 2

[0101] This example is used to illustrate the preparation method of the oily material suitable for producing needle coke according to the present invention.

[0102] According to the method described in embodiment 1, the difference is:

[0103] In step (2), the conditions for the first stripping treatment include: the temperature is 330°C, the gauge pressure is 0.15MPa, and the residence time is 1.8h;

[0104] In step (3), the conditions for the second stripping treatment include: the temperature is 350°C, the gauge pressure is 0.15MPa, and the residence time is 1h;

[0105] In step (4), the heating temperature of the hydrogenation feed preheater is 300°C, and the conditions for hydrotreating include: the temperature is 350°C, the reaction hydrogen partial pressure is 3MPa, and the hydrogen-to-oil ratio is 200Nm 3 / m 3 , with a volumetric space velocity of 1h -1 ;

[0106] In step (5), the conditions of the third stripping treatment include: the temperature is 300°C, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com