Transparent polystyrene with capacity scale of 50,000 tons or above as well as production equipment and process of transparent polystyrene

A transparent polystyrene and production equipment technology, applied in the field of polystyrene materials, can solve the problems of unsatisfactory transparency and mechanical properties, and achieve safe and controllable production process, good environmental protection effect, low content of oligomers and colored impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

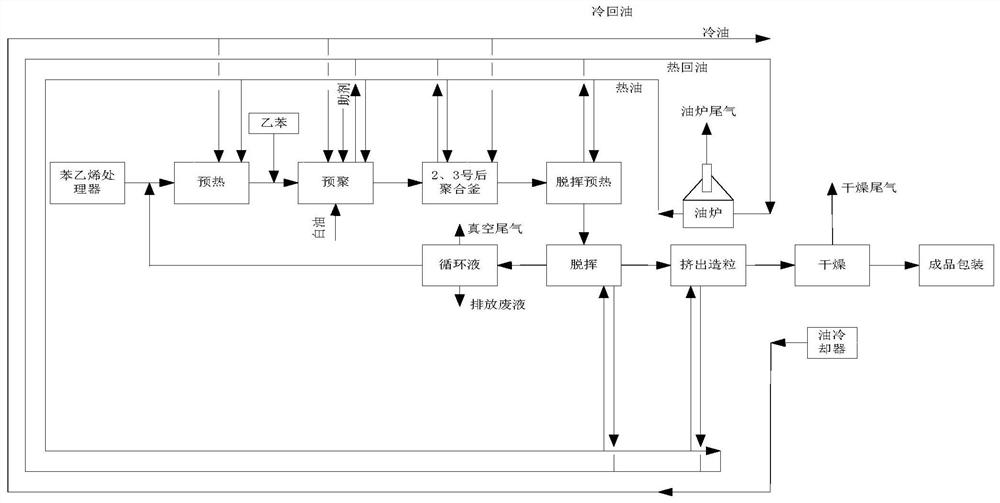

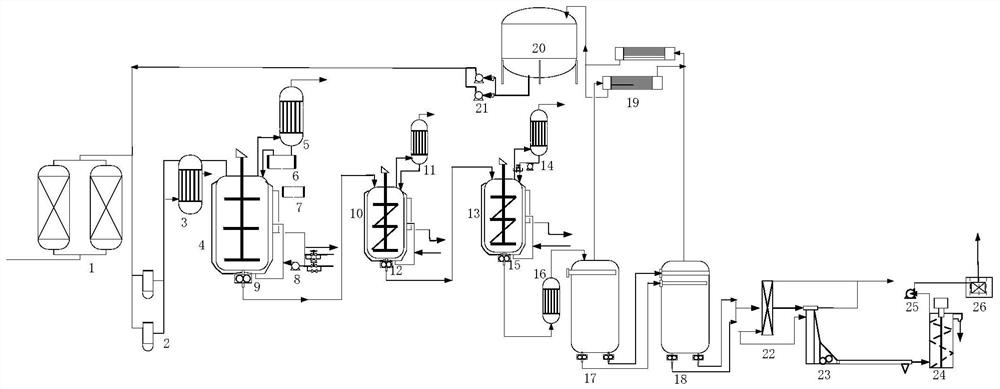

[0031]The present invention will be further described below with reference to the accompanying drawings.

[0032]The transparent polystyrene adopted by the present invention is:

[0033]A, Styrene: The purity is greater than 99.9%, colorless transparent liquid, and the amount is 0.960-0.990.

[0034]B, industrial white oil: flash point is greater than 240 ° C, colorless and transparent liquid, and 0.001-0.040.

[0035]C, Internal and outer lubricant: paraffin, zinc stearate, calcium stearate, stearate amide, oleic acid amide, the appearance is white particles or powder, the purity is greater than 99.8%, and two or more or more of the above lubricants are selected. The auxiliary compound use: The amount is 0.001-0.005.

[0036]D, antioxidants: BHT, IRGANOX1076, Irganox1010, Irganox1330: One of the types of which is 0.001-0.010.

[0037]E, oil-soluble blue pigments (violet): 10-50 ppm.

[0038]F, ultraviolet absorber and light stabilizer: Tinuvin327, Tinuvin UVP, Tinuvin320, Tinuvin328, Tinuvin770, Tinuvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com