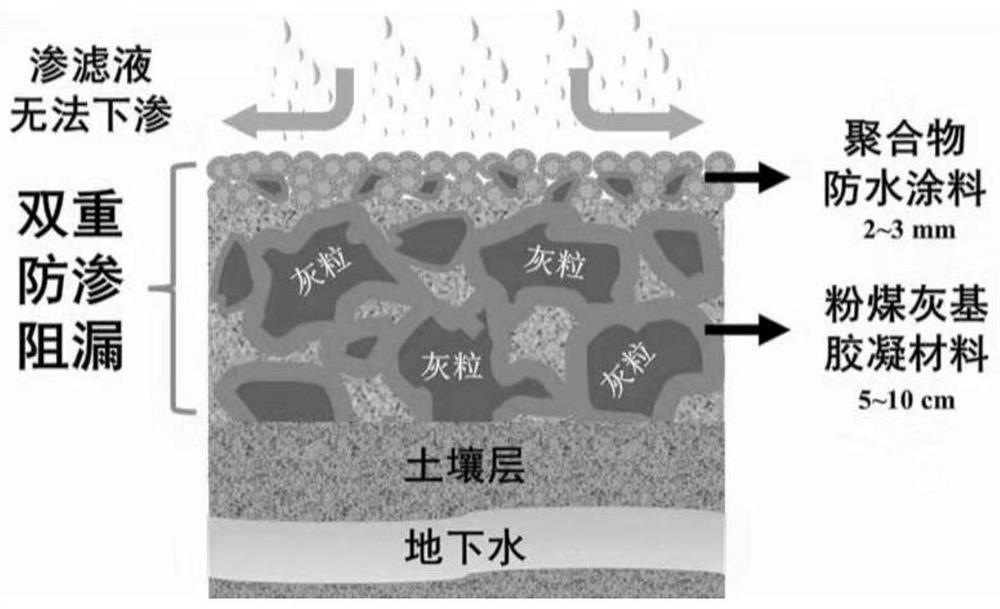

A double anti-seepage method based on coal-based solid waste

A dual, coal-based technology, applied in solid waste management, earthwork drilling, infrastructure engineering, etc., can solve problems such as membrane damage, failure, and pollutant diffusion, reduce comprehensive disposal costs, prevent leachate infiltration, Good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] fly ash based cementitious material

[0028] Mix 70kg of circulating fluidized bed boiler fly ash and 20kg of circulating fluidized bed boiler fly ash with a particle size of 5-10 μm and 10kg of slag Portland cement with a grade of 32.5, and add 22kg of water and continue to stir evenly, that is, Fly ash based cementitious material. After curing, the 1-day compressive strength measured by a mechanical strength tester was 3.8 MPa, the 3-day compressive strength was 8.5 MPa, and the 7-day compressive strength was 21.6 MPa.

Embodiment 2

[0030] fly ash based cementitious material

[0031] Mix 80 kg of circulating fluidized bed boiler fly ash with a particle size of 5-10 μm and 10 kg of circulating fluidized bed boiler fly ash and 10 kg of ordinary Portland cement with a grade of 32.5. Add 25 kg of water and continue to stir evenly, that is, Fly ash based cementitious material. After curing, the 1-day compressive strength measured by a mechanical strength tester was 3.4 MPa, the 3-day compressive strength was 8.3 MPa, and the 7-day compressive strength was 20.3 MPa.

Embodiment 3

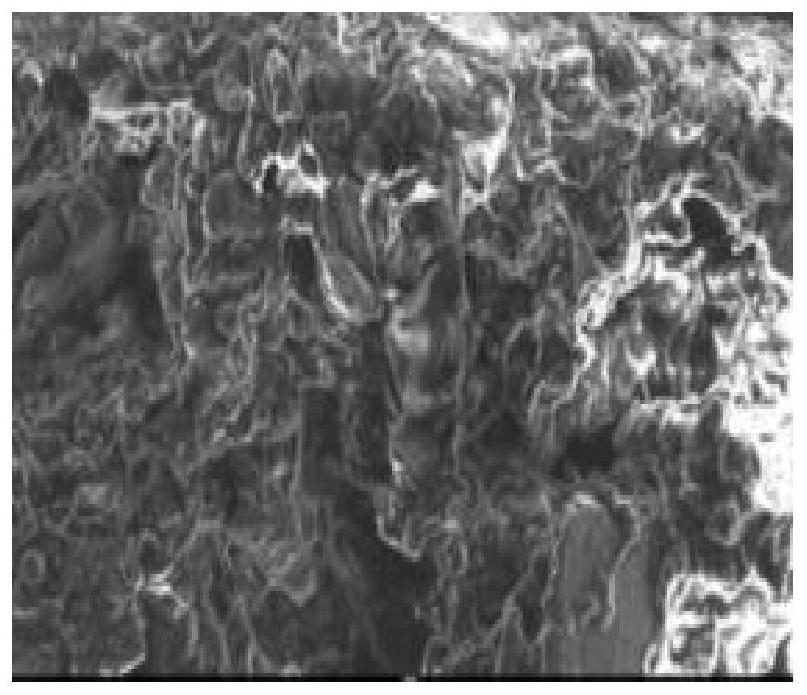

[0033] Polymer Waterproof Coatings

[0034] Mixing 60kg of circulating fluidized bed boiler fly ash with a particle size of 5-10μm and 40kg of slag Portland cement with a label of 32.5 is powder, and after mixing 30kg of S400F type styrene-acrylic emulsion and 40kg of water at low speed for 2min, Add the pre-mixed powder, continue stirring at a constant speed of 600r / min for 15min to obtain a polymer waterproof coating. dump it into Samples were prepared in a circular mold frame, and after 7 days of natural curing, the sample thickness was 2.8 mm. Coating section such as figure 2 As shown, there are no holes inside, and the structure is dense and solid. After 30 minutes of testing with a water impermeability tester, the coating is impermeable. image 3 As shown, the surface is still dense with no obvious holes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com