Wafer cutting fluid

A cutting fluid and wafer technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor reliability, poor bonding performance, static electricity accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of Example 1-6 is as follows: add a certain amount of ultrapure water into the reactor, and start stirring; add oligomeric saponins according to the mass ratio, and stir for 3 minutes; add natural plant extracts according to the mass ratio, and stir for 3 minutes; Add dispersant according to mass ratio and stir for 5 minutes; add wetting agent according to mass ratio and stir for 5 minutes; add amino acid compound according to mass ratio and stir for 5 minutes; add solubilizer according to mass ratio and stir until transparent to obtain wafer cutting fluid.

[0040] The preparation method of Example 7-10 is as follows: add a certain amount of ultrapure water into the reactor, and start stirring; add oligomeric saponins according to the mass ratio, and stir for 3 minutes; add natural plant extracts according to the mass ratio, and stir for 3 minutes; Add dispersant according to mass ratio and stir for 5 minutes; add wetting agent according to mass ...

Embodiment 25

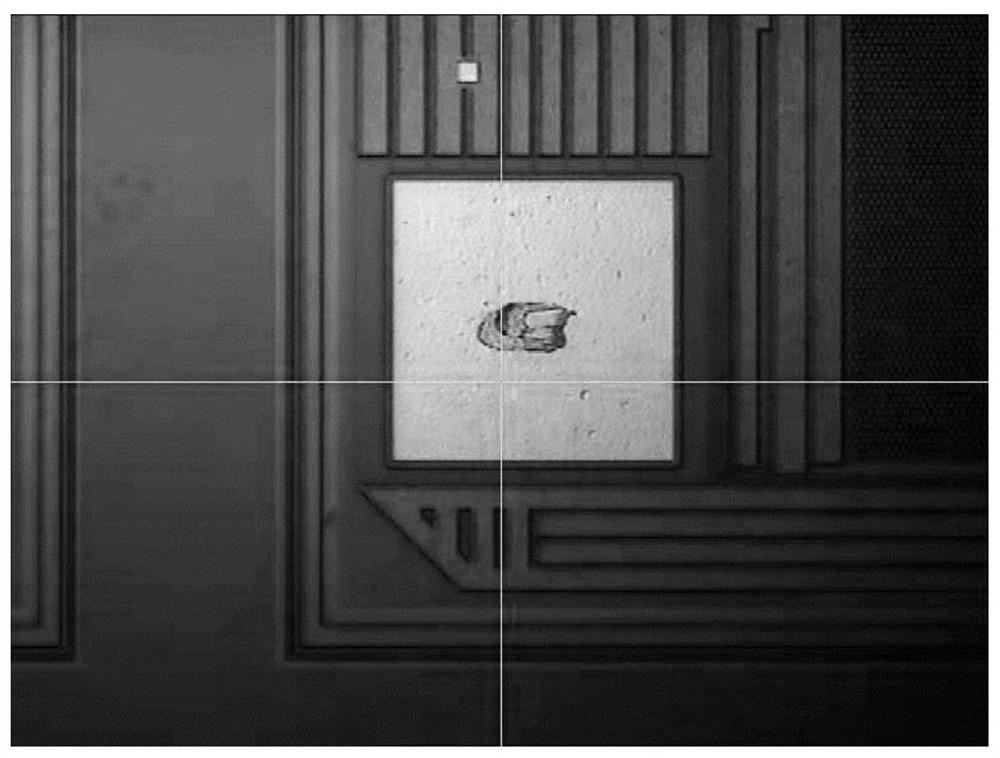

[0051] Example 25 Comparative description of particle residue and metal corrosion

[0052] The effect detection of the following embodiments all adopts the following method: cut a 12-inch wafer with a Disco6362 wafer cutting machine, and the dilution factor of the cutting fluid is 3000 times, and observe with a metallographic microscope whether there are particles remaining on the surface of the wafer after cutting; in addition, the cutting Afterwards, the wafer was placed in the air, and the surface corrosion conditions were observed at 8 hours, 12 hours, 24 hours, and 36 hours, respectively.

[0053] The particle residual result of table 4 embodiment and comparative example 1

[0054]

[0055]

[0056] Among them: the minimum detection limit of ICP is 0.2ppm, and the result below the detection limit is recorded as N.D.; NG means: unqualified; OK: qualified.

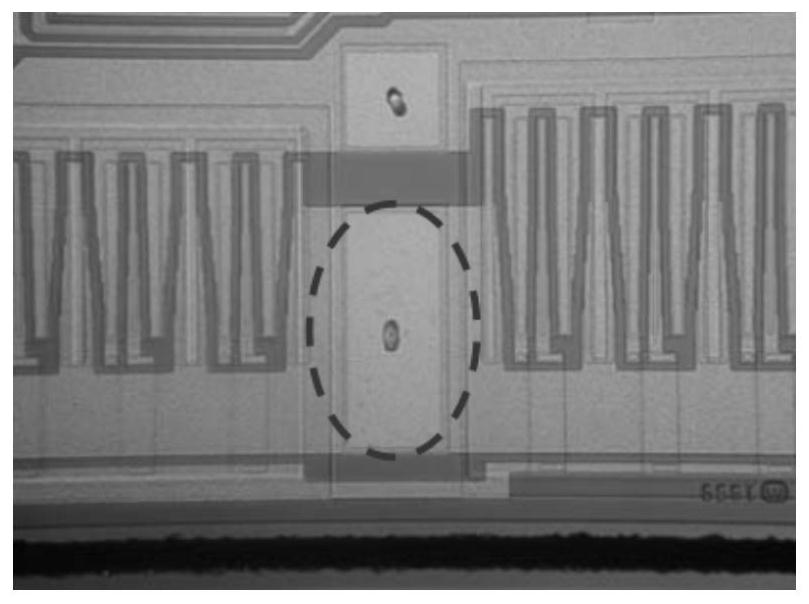

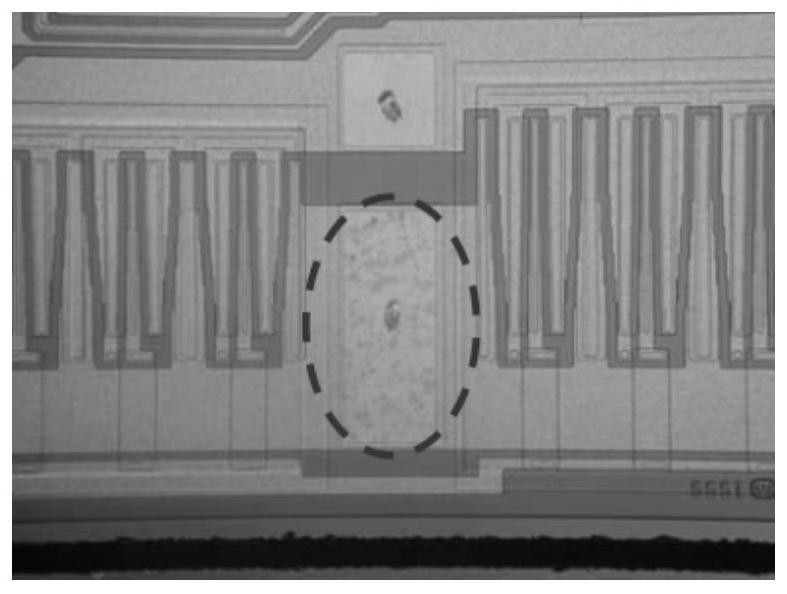

[0057] Comparison of whether there are particles left after cutting figure 1 with figure 2 as shown, figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com