A preparation method of high thermal conductivity graphite airgel-based composite thermal interface material

A technology of high thermal conductivity graphite and thermal interface materials, which is applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., and can solve problems such as low elastic modulus, reduced contact thermal resistance, and large elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

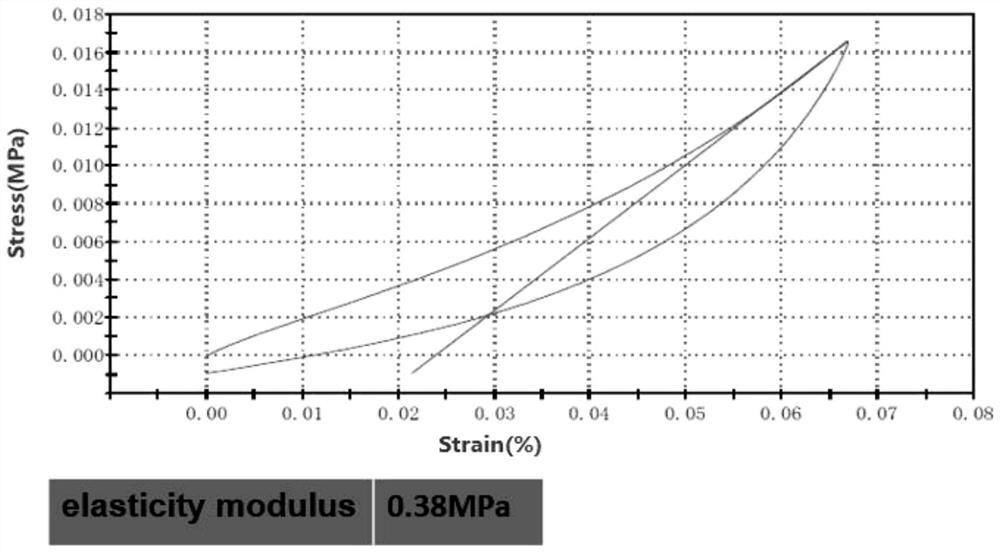

Embodiment 1

[0032] In this embodiment, the injection molding method is used to prepare graphene airgel / polymer composite flexible heat-conducting film, and its preparation method is as follows:

[0033] (1) Weigh 0.516 g of ascorbic acid, and add 13.5 mL of deionized water into a beaker.

[0034] (2) Place the beaker containing the ascorbic acid solution on a magnetic stirrer, and at the same time, add 1.5 ml of GO aqueous solution with a concentration of 10 mg / mL to the centrifuge tube with a pipette gun. The stirring time was 10 min to ensure that the GO aqueous solution and the ascorbic acid solution were mixed evenly.

[0035] (3) Transfer the uniformly mixed salt solution in step (2) to the reaction kettle, and place the reaction kettle in a blast drying oven at 120° C. for 12 hours.

[0036] (4) Transfer the reaction product obtained in step (3) to a centrifuge tube, rinse with deionized water and ethanol three times respectively.

[0037] (5) Place the sample cleaned in step (4) ...

Embodiment 2

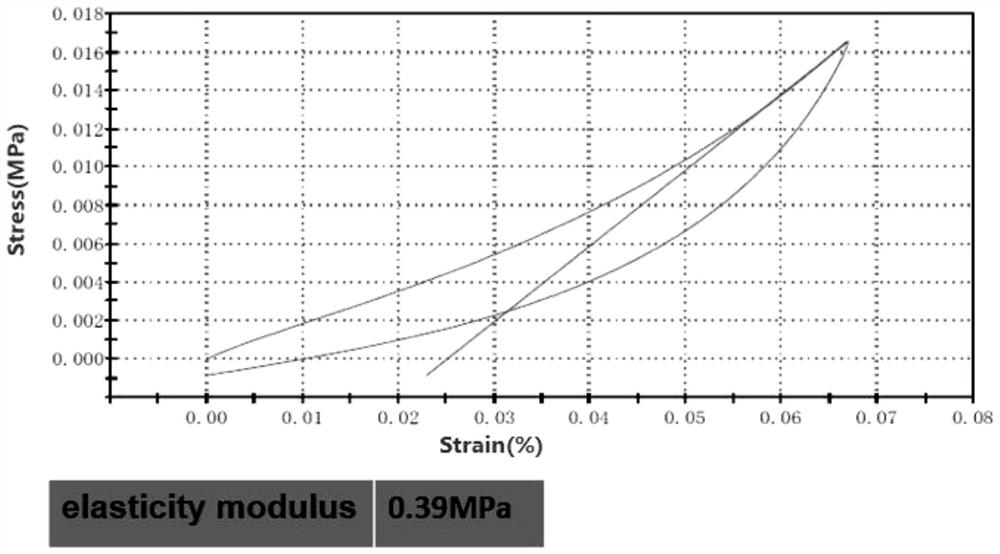

[0044] In this embodiment, the injection molding method is used to prepare graphene airgel / polymer composite flexible heat-conducting film, and its preparation method is as follows:

[0045] (1) Weigh 0.516 g of ascorbic acid, and add 11.5 mL of deionized water into a beaker.

[0046] (2) Place the beaker containing the ascorbic acid solution on a magnetic stirrer, and at the same time, add 4.5 ml of GO aqueous solution with a concentration of 10 mg / mL to the centrifuge tube with a pipette gun. The stirring time was 60min to ensure that the GO aqueous solution and the ascorbic acid solution were mixed evenly.

[0047] (3) Transfer the uniformly mixed salt solution in step (2) to the reaction kettle, and place the reaction kettle in a blast drying oven at 180° C. for 2 hours.

[0048] (4) Transfer the reaction product obtained in step (3) to a centrifuge tube, rinse with deionized water and ethanol three times respectively.

[0049] (5) Place the sample cleaned in step (4) an...

Embodiment 3

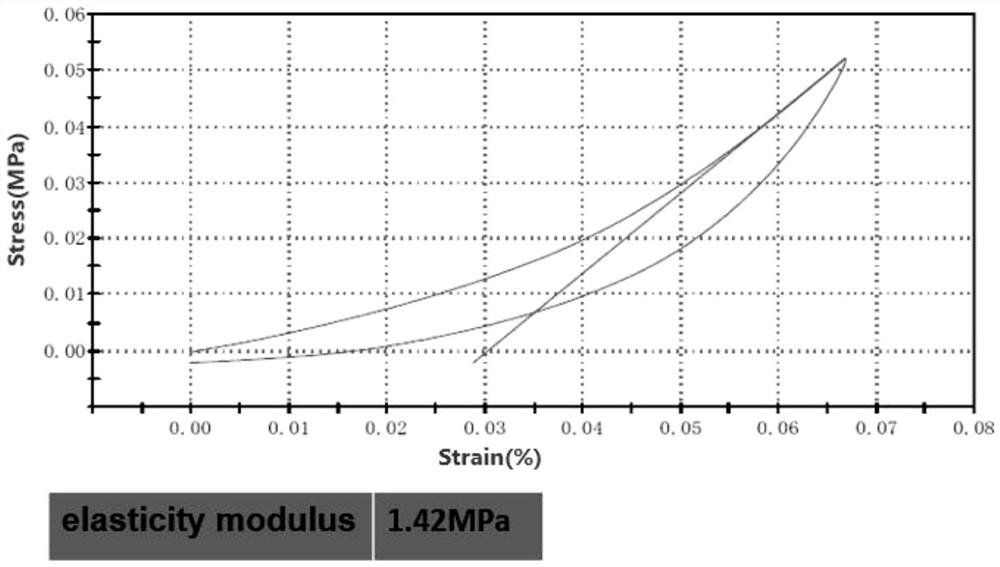

[0056] In this embodiment, the injection molding method is used to prepare graphene airgel / polymer composite flexible heat-conducting film, and its preparation method is as follows:

[0057] (1) Weigh 0.516 g of ascorbic acid, and add 7.5 mL of deionized water into a beaker.

[0058] (2) Place the beaker containing the ascorbic acid solution on a magnetic stirrer, and at the same time, add 7.5 ml of GO aqueous solution with a concentration of 10 mg / mL to the centrifuge tube with a pipette gun. The stirring time was 120min to ensure that the GO aqueous solution and the ascorbic acid solution were mixed evenly.

[0059] (3) Transfer the uniformly mixed salt solution in step (2) to the reaction kettle, and place the reaction kettle in a blast drying oven at 180° C. for 2 hours.

[0060] (4) Transfer the reaction product obtained in step (3) to a centrifuge tube, rinse with deionized water and ethanol three times respectively.

[0061] (5) Place the sample cleaned in step (4) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com