Maleic anhydride/N-phenylmaleimide/alpha-methylstyrene copolymer microsphere as well as preparation method and application thereof

A technology of maleimide and methyl styrene, which is applied in the field of polymer polymerization and can solve problems such as polymer pollution and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The second aspect of the present invention provides a kind of preparation method of maleic anhydride / N-phenylmaleimide / α-methylstyrene copolymer microsphere, described method comprises the following steps:

[0039] (1) In an inert atmosphere, the polymerization monomer and the initiator are dissolved in the reaction medium to form a homogeneous solution;

[0040] (2) After the homogeneous solution is subjected to a polymerization reaction to obtain a copolymer emulsion suspension, centrifugal separation obtains the maleic anhydride / N-phenylmaleimide / α-methylstyrene copolymer microspheres;

[0041] Wherein, the polymerized monomer is comonomer I, comonomer II and comonomer III;

[0042] The comonomer I has a structure shown in formula (4)

[0043]

[0044] The comonomer II has a structure shown in formula (5)

[0045]

[0046] The comonomer III has a structure shown in formula (6)

[0047]

[0048] In the present invention, the method of copolymerization is a...

Embodiment 1

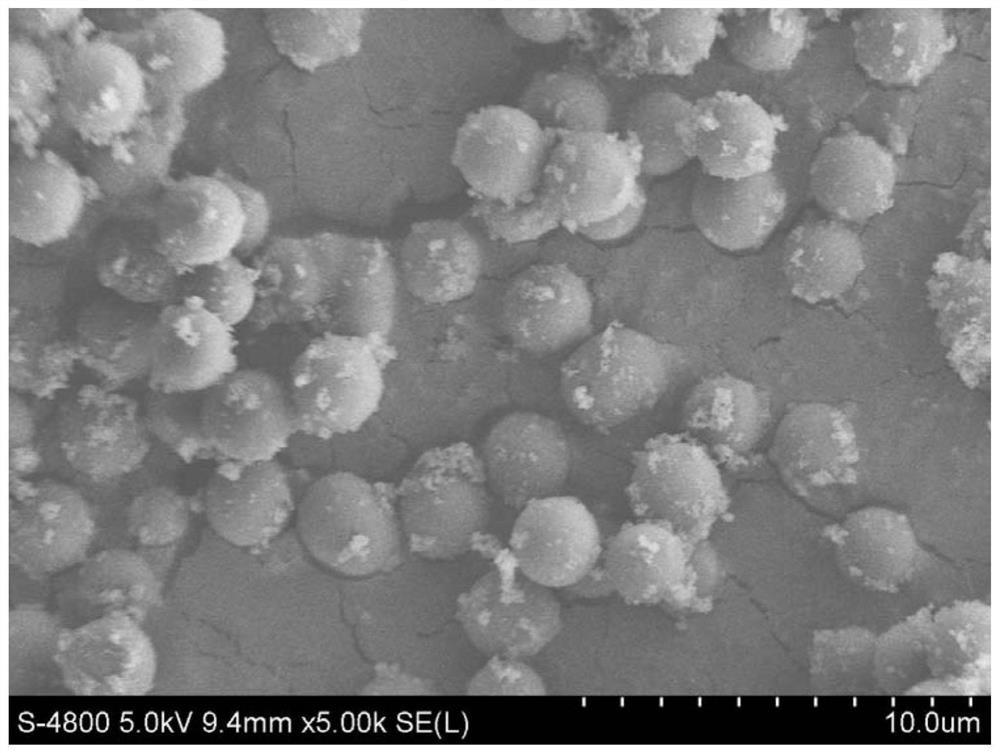

[0085] Add 10g of comonomer I, 0.8g of azobisisobutyronitrile, 5.9g of comonomer III, 8.65g of comonomer II and 87.8g of isoamyl acetate into a 500mL three-necked flask. Minutes, the three-neck flask was moved into a 90°C water bath, and reacted for 3 hours. After the reaction was completed, the obtained polymer emulsion suspension was centrifuged at a speed of 2000rad / min for 20 minutes to obtain 17.89g of polymer microspheres A1, which corresponded to polymerization The material yield is 73.5%. The polymer microspheres are 1500 nm in size.

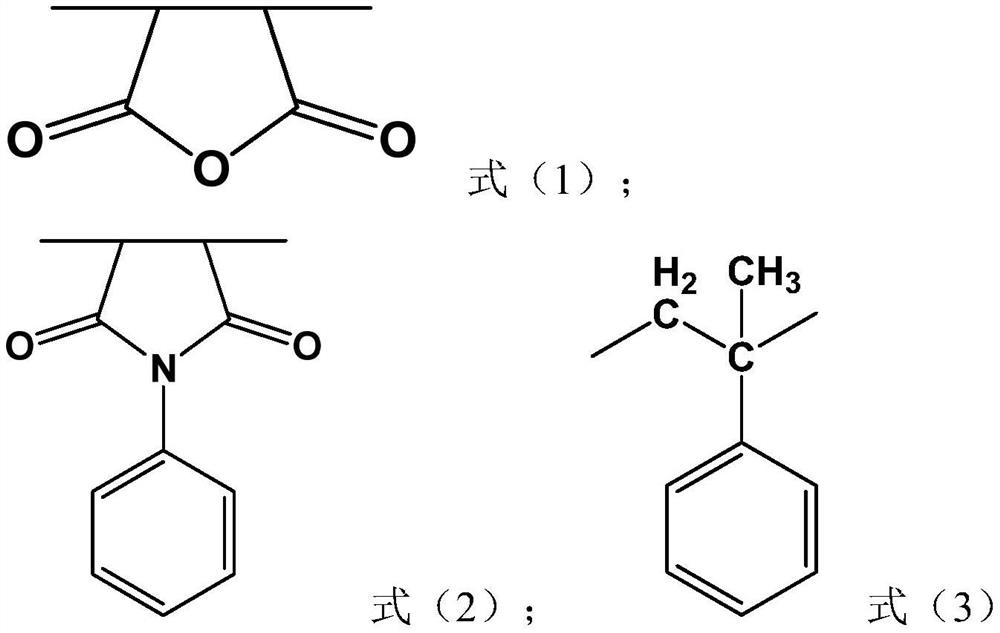

[0086] The polymer microsphere A1 was carried out 1 H NMR measures, and records based on the total molar weight of each structural unit in the polymer, the molar content of the structural unit shown in the formula (1) is 52%, and the molar content of the structural unit described in the formula (2) is 29%, The molar content of the structural unit of formula (3) is 19%.

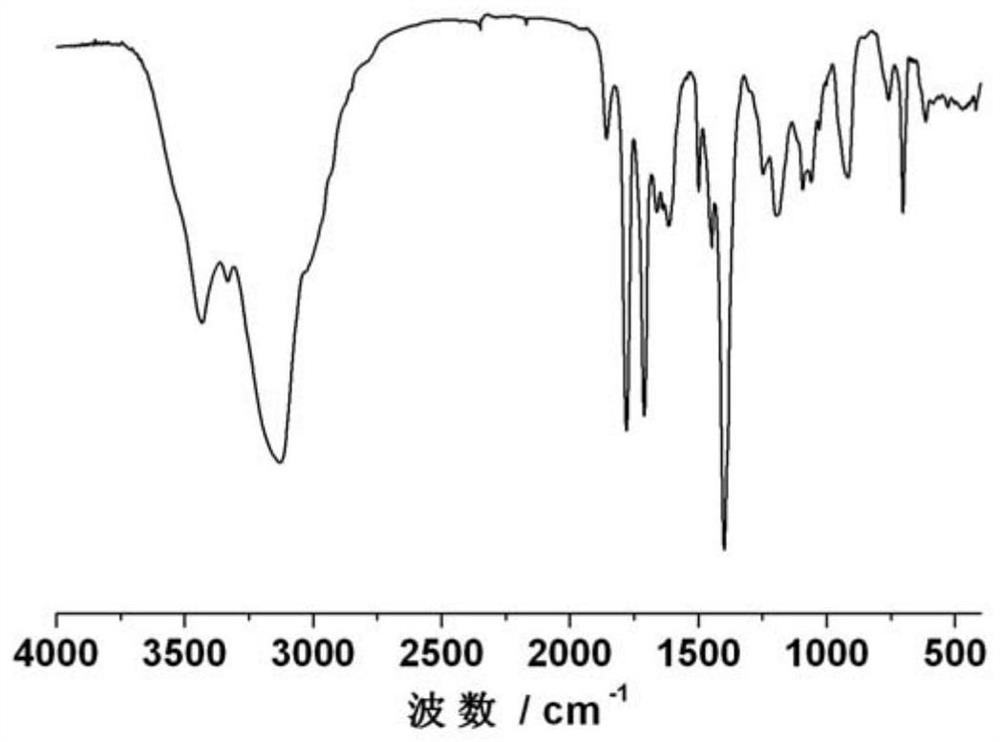

[0087] Such as figure 1 FI-IR image of the copolymer microspher...

Embodiment 2

[0090] Add 15g of comonomer I, 0.3g of azobisisobutyronitrile, 7g of comonomer III, 8g of comonomer II and 120g of butyl benzoate into a 500mL three-necked flask. The flask was moved into a water bath at 60°C and reacted for 24 hours. After the reaction was completed, the obtained polymer emulsion suspension was centrifuged at a speed of 2000 rad / min for 20 minutes to obtain 18.32 g of polymer microspheres A2, corresponding to a polymer yield of 77 %. The polymer microspheres are 2000 nm in size.

[0091] The polymer microsphere A2 was carried out 1 H NMR measures, and records based on the total molar weight of each structural unit in the polymer, the molar content of the structural unit shown in the formula (1) is 48%, and the molar content of the structural unit described in the formula (2) is 30m%, The molar content of the structural unit of formula (3) is 22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com