A preparation method of silica airgel ink for 3D direct writing printing

A silicon oxide airgel and ink technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of unfavorable low density, high porosity airgel materials, high solid content, and complexity, and achieve Good effect of maintaining solvent effect, reducing solvent volatilization loss and improving viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

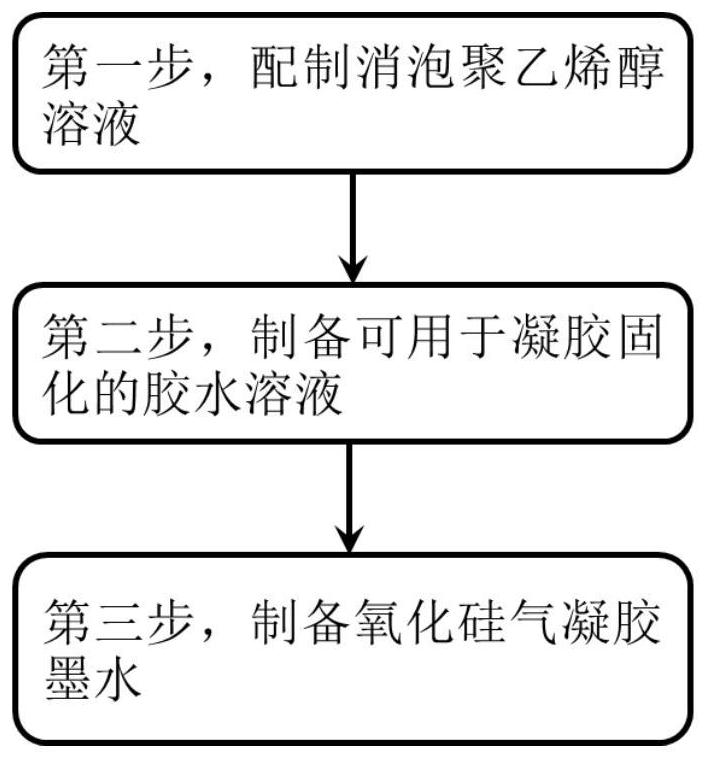

[0031] This embodiment provides a preparation method of silica aerogel ink for 3D direct writing printing (the operation process is as follows: figure 1 shown), which includes the following steps:

[0032] The first step, prepare defoaming polyvinyl alcohol solution, the method is:

[0033] In an airtight container, the polyvinyl alcohol solid particles are slowly stirred and dissolved in an ethanol-water solvent system under heating at 80° C. to obtain a defoaming polyvinyl alcohol solution with a solid content of 8 wt %. In the preparation process, the mass ratio of water and ethanol is controlled at 9:1;

[0034] The second step is to prepare a glue solution that can be used for gel curing by:

[0035]A defoaming polyvinyl alcohol solution, glycerol and water were added to the aqueous silica sol with a solid content of 40%, and the solution was slowly stirred for 15 minutes at room temperature to obtain a homogeneous, stable, gel-solidifying solution. In this process, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com