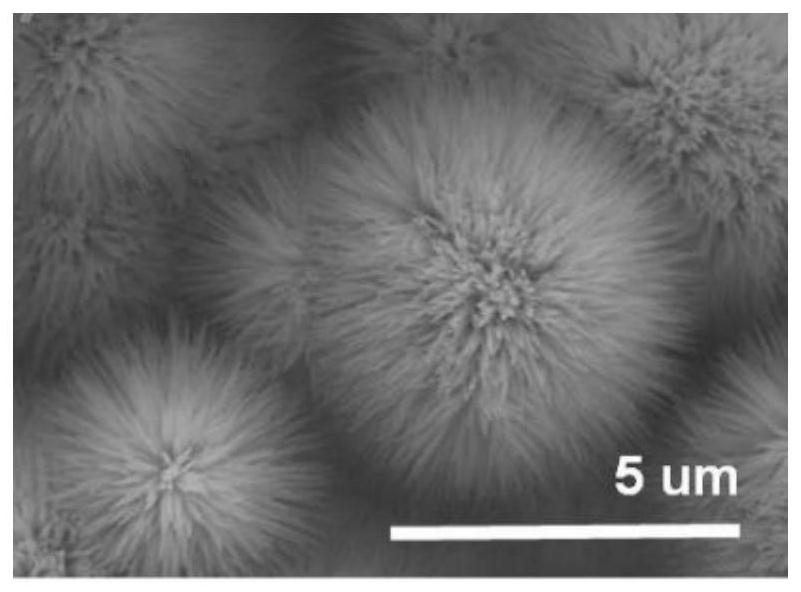

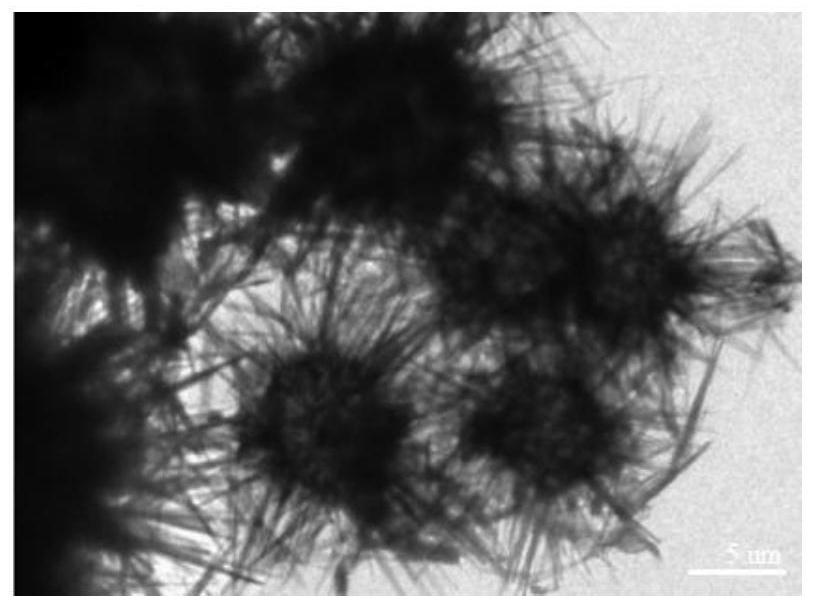

A sea urchin-like p-doped zrmo 2 o 8 Preparation method of nano catalyst

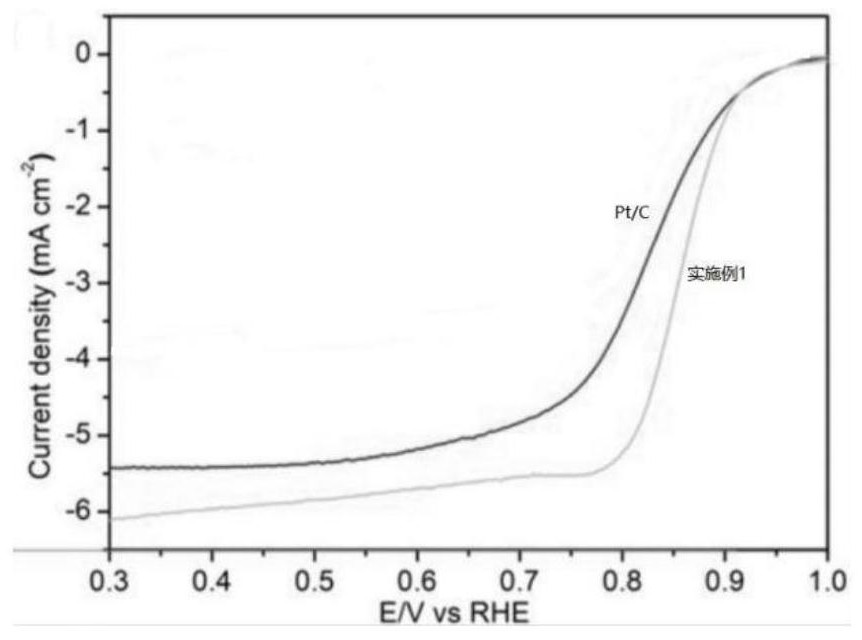

A nano-catalyst and sea urchin-like technology, which is applied in the field of preparation of sea urchin-like P-doped ZrMo2O8 nano-catalysts, can solve the problems that the catalytic performance cannot reach the catalytic performance of noble metals, the cathode oxygen reduction reaction is slow, and it is not suitable for large-scale production. Improve the electrocatalytic oxygen reduction catalytic performance, improve the electrochemical performance, and be suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A sea urchin-like P-doped ZrMo 2 o 8 Nanocatalyst, prepared by the following steps:

[0027] S1: Weigh 2g of zirconium nitrate and 1.5g of sodium molybdate into 50ml of deionized water, sonicate for 30 minutes to dissolve completely, then drop ammonia water into the solution, adjust the pH of the solution to 8.2, let the solution stand for 7 hours, and then use Rinse the product 5 times with deionized water and ethanol;

[0028] S2: Add the S1 product into deionized water, stir for 20 minutes to disperse evenly, then add 0.4g sodium hypophosphite, continue stirring for 15 minutes, then transfer the mixed solution into a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 120°C for 12 hours. After the reaction, ultrasonic cleaning with deionized water 4 times;

[0029] S3: Add the S2 product into 25ml of N, N-dimethylformamide, mix it evenly with ultrasound, then add 0.5g of F127, stir for 25min, transfer the beaker containing the mixed solution in...

Embodiment 2

[0032] A sea urchin-like P-doped ZrMo 2 o 8 Nanocatalyst, prepared by the following steps:

[0033] S1: Weigh 2g of zirconium nitrate and 1g of sodium molybdate into 40ml of deionized water, sonicate for 20min to dissolve completely, then add ammonia water dropwise into the solution, adjust the pH of the solution to 8, let the solution stand for aging for 6h, and then use Wash the product 4 times with deionized water and ethanol;

[0034] S2: Add the S1 product into deionized water, stir for 20 minutes to disperse evenly, then add 0.34g of sodium hypophosphite, continue stirring for 10 minutes, then transfer the mixed solution into a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 100°C for 15 hours. After the reaction, ultrasonic cleaning with deionized water 4 times;

[0035] S3: Add the S2 product into 24ml of N, N-dimethylformamide, and mix it evenly with ultrasound, then add 0.4g of F127, stir for 20min, transfer the beaker containing the mixed ...

Embodiment 3

[0038] A sea urchin-like P-doped ZrMo 2 o 8 Nanocatalyst, prepared by the following steps:

[0039] S1: Weigh 2g of zirconium nitrate and 2g of sodium molybdate into 60ml of deionized water, sonicate for 40 minutes to dissolve completely, then add ammonia water dropwise into the solution, adjust the pH of the solution to 8.5, let the solution stand for aging for 8 hours, and then use it Rinse the product 6 times with deionized water and ethanol;

[0040] S2: Add the S1 product into deionized water, stir for 30 minutes to disperse evenly, then add 0.5g of sodium hypophosphite, continue stirring for 20 minutes, then transfer the mixed solution into a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 150°C for 10 hours. After the reaction, ultrasonic cleaning with deionized water 5 times;

[0041] S3: Add the S2 product to 26ml of N,N-dimethylformamide, mix it evenly by ultrasonic, then add 0.67g of F127, stir for 30min, transfer the beaker containing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com