Carbon-supported palladium copper tantalum nitride nano-electrocatalyst for direct methanol and formic acid fuel cells and preparation method thereof

A formic acid fuel cell and electrocatalyst technology, which is applied in nanotechnology, fuel cells, battery electrodes and other directions for materials and surface science, can solve problems such as poisoning, achieve simple and controllable operation, improve adsorption, and avoid agglomeration effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

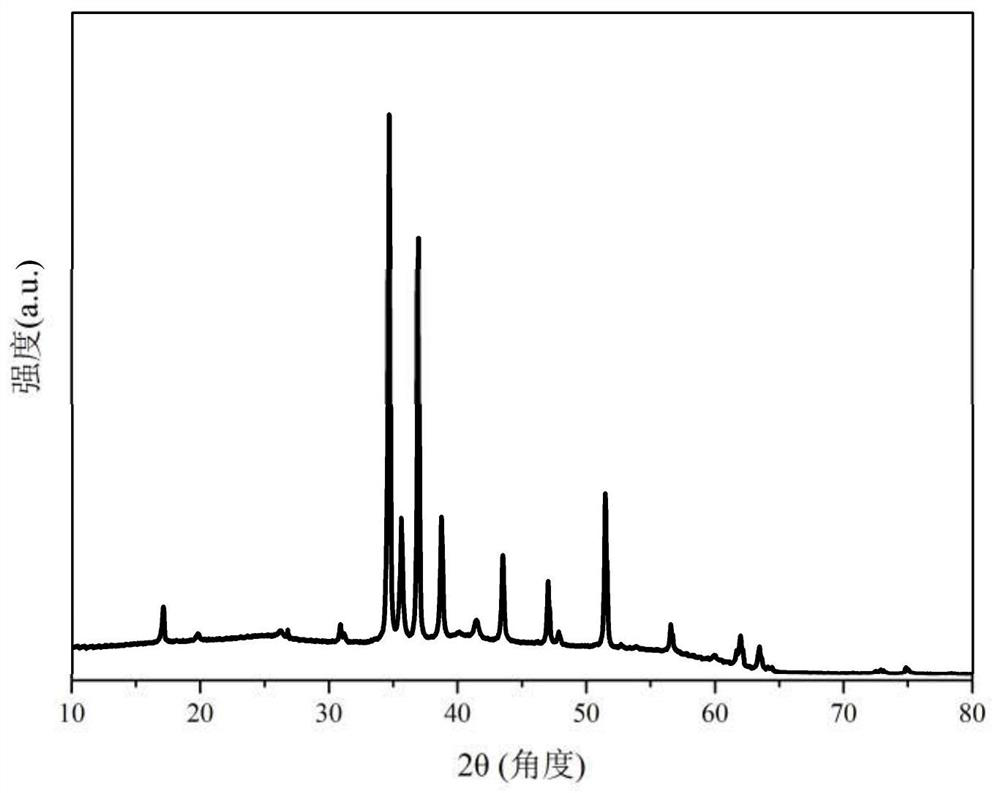

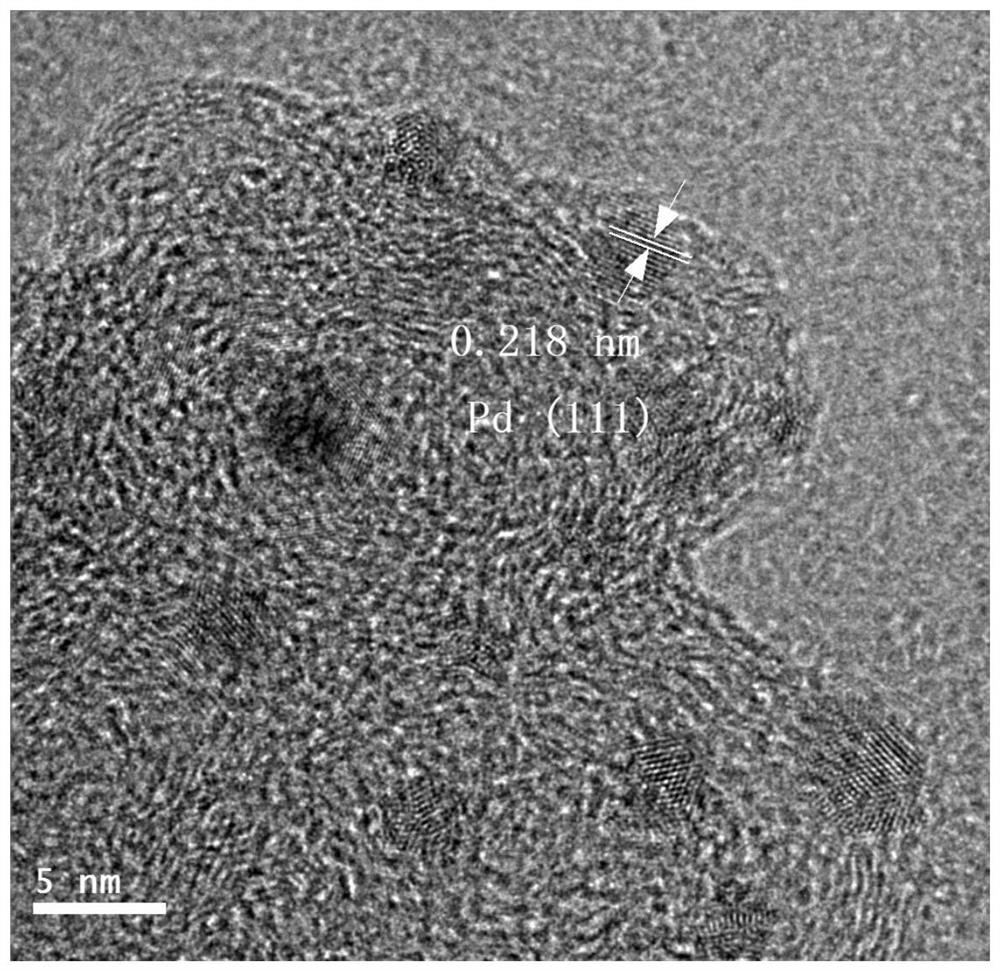

[0028] In this embodiment, a method for preparing a carbon-supported palladium-copper tantalum nitride nano-electrocatalyst for direct methanol and formic acid fuel cells, 135 mg of tantalum nitride, 67.5 mg of conductive carbon black and 33.75 mL of ethylene glycol are added to the container, and placed Stir on a magnetic stirrer for 15 minutes, and ultrasonically treat for 120 minutes, so that tantalum nitride and conductive carbon black are uniformly dispersed in ethylene glycol, and mixture A is obtained.

[0029] Add 4.9 mg of sodium chloropalladate, 0.5 mg of copper chloride and 40 mg of sodium citrate to 8 mL of the above mixture A, place it on a magnetic stirrer and stir for 30 minutes, then raise the temperature to 120°C and stir for 5 hours, wherein sodium chloropalladate and chlorine Copper chloride is reduced to metal palladium and copper respectively to obtain a solid-liquid mixture, which is then cooled to room temperature.

[0030] Wash the solid-liquid mixture ...

Embodiment 2

[0035] In this embodiment, a method for preparing a carbon-supported palladium tantalum nitride nano-electrocatalyst for direct methanol and formic acid fuel cells, 135mg tantalum nitride, 67.5mg conductive carbon black and 33.75mL ethylene glycol are added to the container, and placed in Stir on a magnetic stirrer for 30 minutes, and ultrasonically treat for 120 minutes, so that tantalum nitride and conductive carbon black are uniformly dispersed in ethylene glycol, and mixture A is obtained.

[0036] Add 4.9 mg of sodium chloropalladate and 40 mg of sodium citrate to 8 mL of the above mixture A, place on a magnetic stirrer and stir for 30 minutes, then raise the temperature to 120 ° C and stir for 5 hours, wherein the sodium chloropalladate is reduced to metal palladium to obtain solid liquid mixture, and then cooled to room temperature.

[0037]Wash the solid-liquid mixture cooled to room temperature with deionized water and absolute ethanol until no ethylene glycol, sodium...

Embodiment 3

[0040] In this embodiment, a method for preparing a carbon-supported palladium-copper tantalum nitride nano-electrocatalyst for direct methanol and formic acid fuel cells, 135 mg of tantalum nitride, 67.5 mg of conductive carbon black and 33.75 mL of ethylene glycol are added to the container, and placed Stir on a magnetic stirrer for 20 minutes, and ultrasonically treat for 60 minutes, so that tantalum nitride and conductive carbon black are uniformly dispersed in ethylene glycol, and mixture A is obtained.

[0041] Add 4.9mg of sodium chloropalladate, 0.5mg of copper chloride and 40mg of sodium citrate to 8mL of the above mixture A, place it on a magnetic stirrer and stir for 30min, then raise the temperature to 100°C and stir for 6h, in which sodium chloropalladate and chlorine Copper chloride is reduced to metal palladium and copper respectively to obtain a solid-liquid mixture, which is then cooled to room temperature.

[0042] Wash the solid-liquid mixture cooled to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com