Preparation method of zirconia all-ceramic tooth

A technology of zirconia and porcelain teeth, which is applied in the field of preparation of zirconia all-ceramic teeth, which can solve the problems of increased risk of fracture, low solid phase content, and unsuitability for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

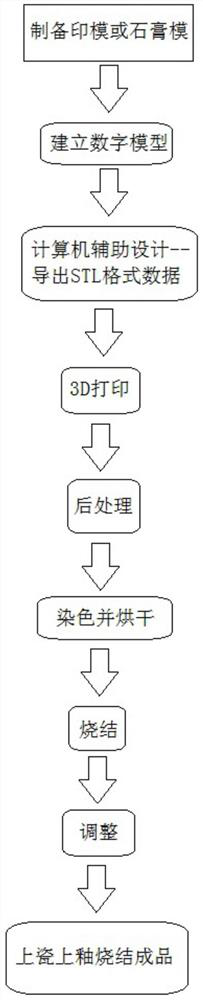

[0027] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0028] see figure 1 In this embodiment, a method for preparing a zirconia all-ceramic tooth adopts a CAD / CAM system. The process is that the doctor prepares the tooth clinically. The intraoral scanner was used to obtain data), and the shape of the crown was designed by computer aid. The data is processed into a finished product by a jet 3D printer. After cleaning, dyeing, and sintering, it is tried on the model, and then adjusted, porcelain, and glazed to complete the production. Taking the posterior tooth restoration as an example, the specific steps are as follows:

[0029] (1) Use an intraoral scanner or clinically prepare impressions or plaster casts. If clinical impressions are used, design a tray with viscous substances and place them in the patient's mouth to form impressions on the back of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com