Design and manufacture method of incisal-end positioning windowless veneer without shoulder

A production method and veneer technology, which can be used in medical science, filling teeth, adding protective layers, etc., and can solve problems such as insufficient accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0020] A method for designing and manufacturing a shoulderless window-opening veneer with incisal positioning of the present invention has the following steps:

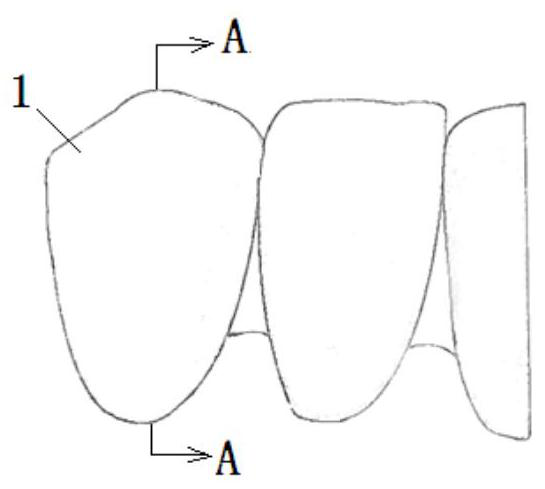

[0021] 1) Design the veneer wax pattern on the window-less veneer preparation model, using manual wax carving or computer-aided design;

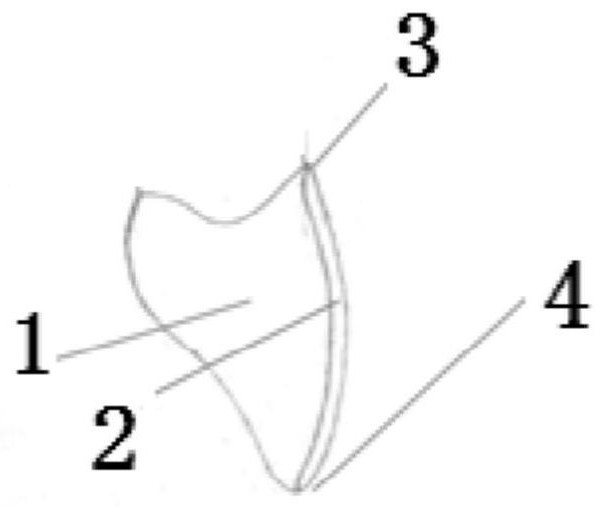

[0022] 2) The gingival edge of the veneer wax pattern is designed as a 30-60 degree blade-like edge;

[0023] 3) The edge of the incisal end of the veneer wax-up is designed to be docked with the incisal end of the natural tooth;

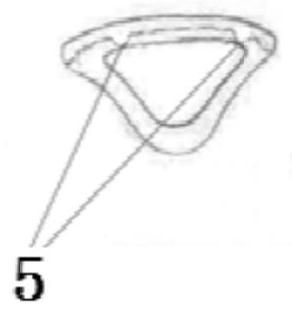

[0024] 4) At the trisection position of the incisal edge of the veneer wax pattern, design two hook-shaped structures covering the incisal end of the tooth, with a width of about 0.5-1mm and a thickness of about 0.5mm;

[0025] 5) Use casting, CNC cutting or 3D printing methods to print wax patterns, or use CNC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com