Treatment process for improving PUR reaction type hot melt adhesive production yield and jig thereof

A processing technology, hot-melt adhesive technology, applied in the field of adhesive, can solve problems such as out-of-sync, uneven glue, pulling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

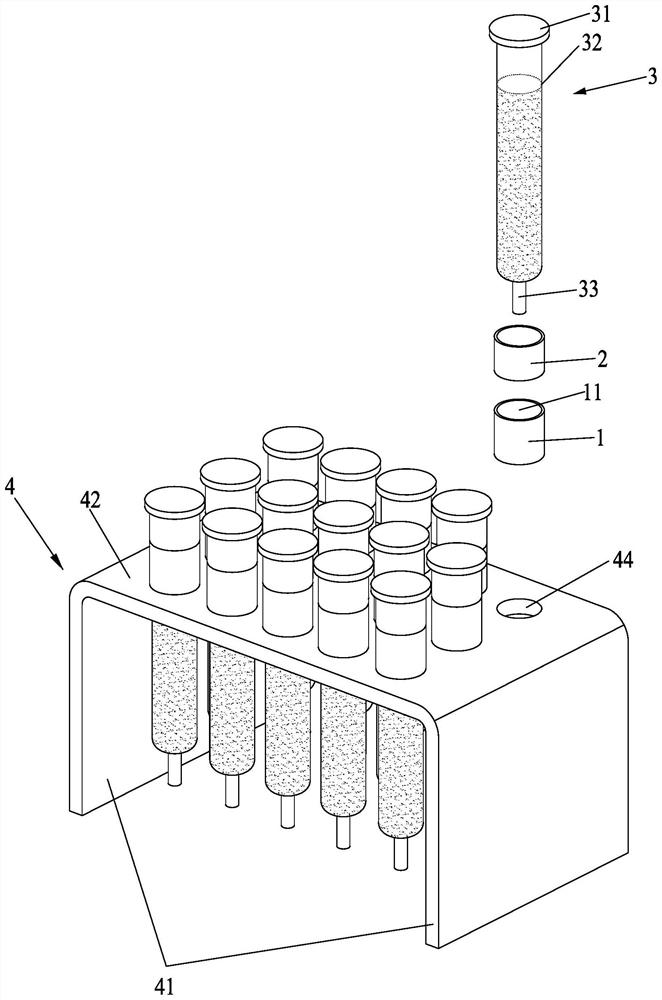

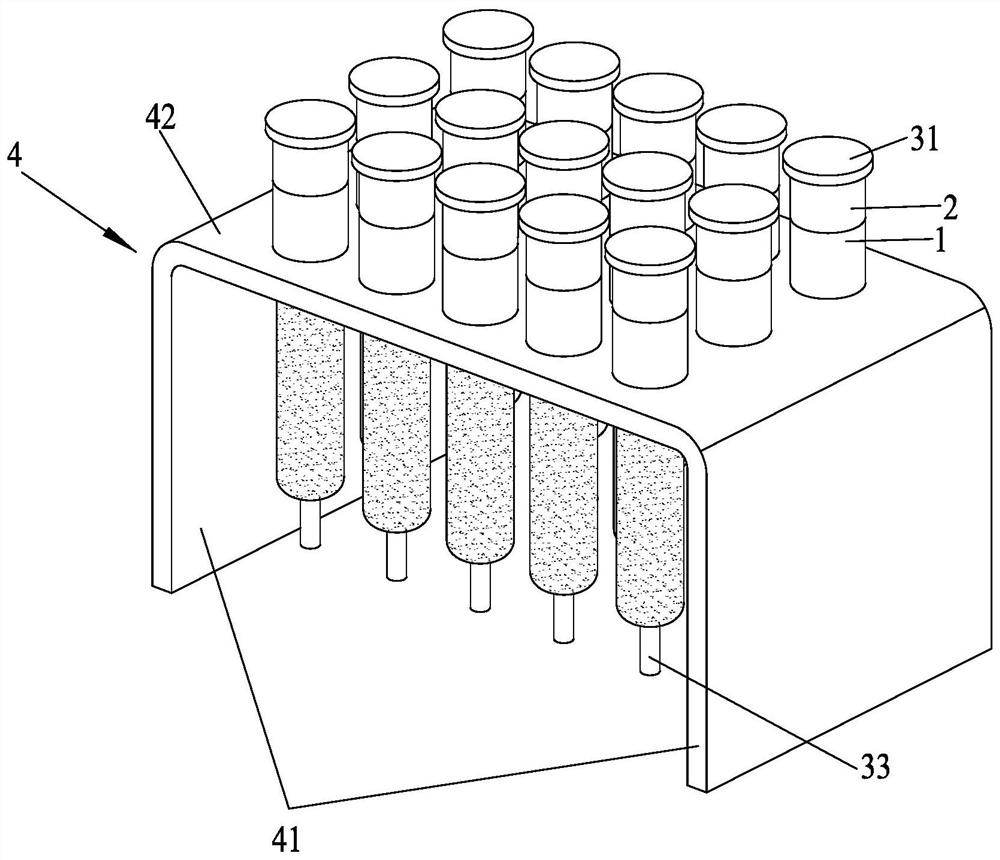

[0034] Such as figure 1 , 2 As shown, a jig for improving the production yield of PUR reactive hot melt adhesives includes a plurality of metal collars 1 with an initial temperature of W, a plurality of heat insulating gaskets 2, each isolation gasket 2 and each metal collar 1 is used with a rubber hose. The metal collar 1 is provided with a heating hole 11 that penetrates up and down. The diameter of the heating hole 11 is slightly larger than the diameter of the rubber hose 3 to be heated. The heating hole 11 (metal collar 1) The longitudinal depth is 6cm; the center of the heat insulation gasket 2 is hollowed out, and the heat insulation gasket 2 is placed outside the rubber hose 3 and between the metal collar 1 and the sealing end cap 31 of the rubber hose 3, so as to isolate the metal collar 1 from the glue Outside the rubber hose 3 at the surface 32, the upper end of the metal collar 1 is two centimeters higher than the glue surface at 32;

[0035] A support frame 4, t...

Embodiment 2

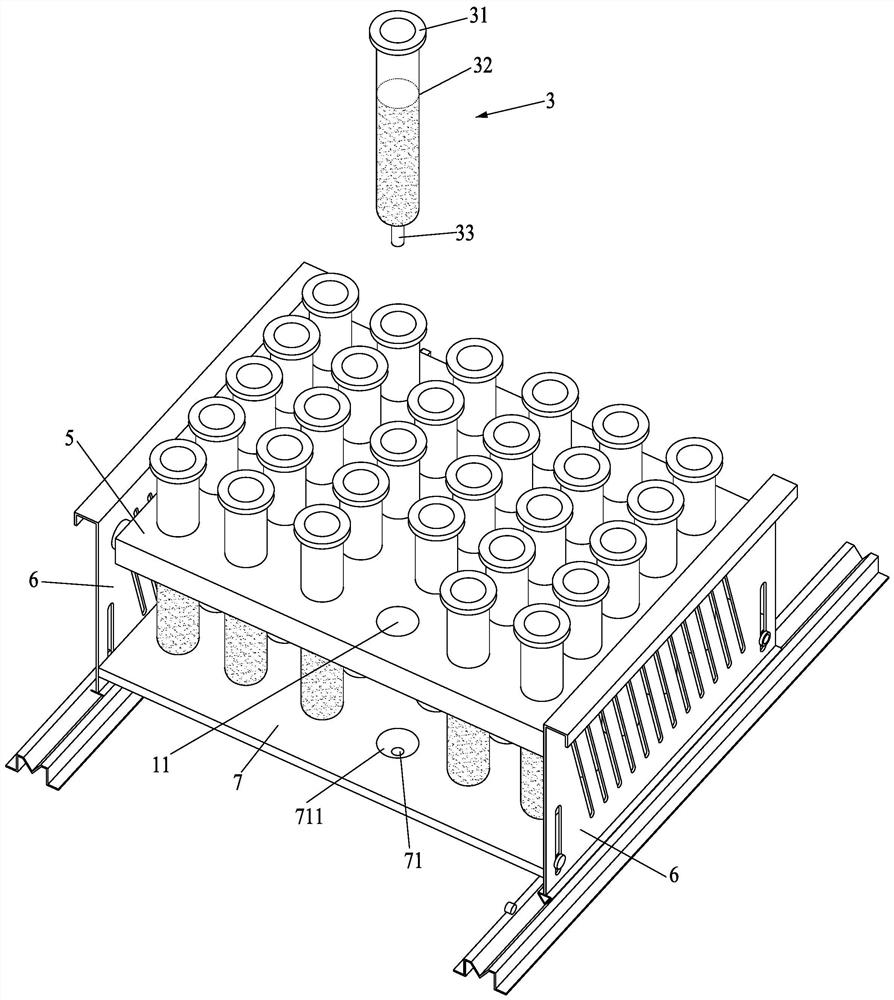

[0046] Such as image 3 , 4 As shown, a jig for improving the production yield of PUR reactive hot melt adhesive includes a heat source device and a positioning structure. The heat source device is an electric heating device with an initial temperature of W, specifically an electric heating plate 5. The electric heating plate 5 is provided with a plurality of heating holes 11 that penetrate up and down. The diameter of the heating holes 11 is slightly larger than the diameter of the rubber hose 3 to be heated. The longitudinal depth of the heating holes 11 is 6 cm (that is, the thickness of the heating plate 5 is 6 cm); Described positioning structure comprises two side fixing plates 6, a positioning plate 7 that can move up and down along both sides fixing plates 6; The two sides of described electric heating plate 5 are fixed on both sides fixing plates 6, are positioned at positioning plate 7 tops and locate The plates 7 are arranged in parallel, and the positioning plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com