Air atomization water absorption felt and preparation process thereof

A technology of air atomization and water-absorbing resin, which is applied in the field of non-woven materials and can solve the problems of hygroscopicity, poor water-locking performance and high crystallinity of non-woven materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

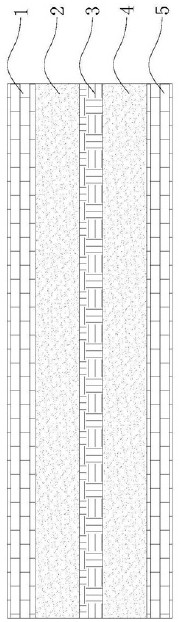

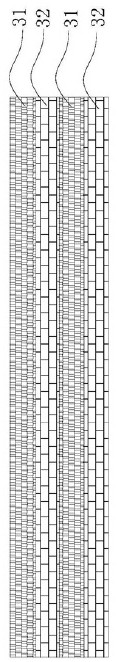

[0024] Such as figure 1 An air-atomized water-absorbing felt as shown comprises a surface layer 1, a water-absorbing resin layer 2, a water-absorbing fiber layer 3, a hydrophilic non-woven fabric layer 4 and a bottom layer 5 from top to bottom, and the water-absorbing resin layer 2 is bonded by colloid. connected to the bottom of the surface layer 1, the water-absorbent fiber layer 3 is bonded to the bottom of the water-absorbent resin layer 2 by colloid, and the hydrophilic non-woven fabric layer 4 is bonded to the bottom of the water-absorbent fiber layer 3 by colloid. Below, the water-absorbent fiber layer 3 is prepared by alternately arranging polypropylene fibers 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com