A stamping system of electronic fuel injection pump

A technology of fuel pumps and stamping machines, applied in the field of stamping systems, can solve the problems of injury, inability to control spring press-fitting in place, and low press-fitting efficiency, so as to prevent relative movement of springs, prevent spring scratches, and increase pressure. The effect of loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

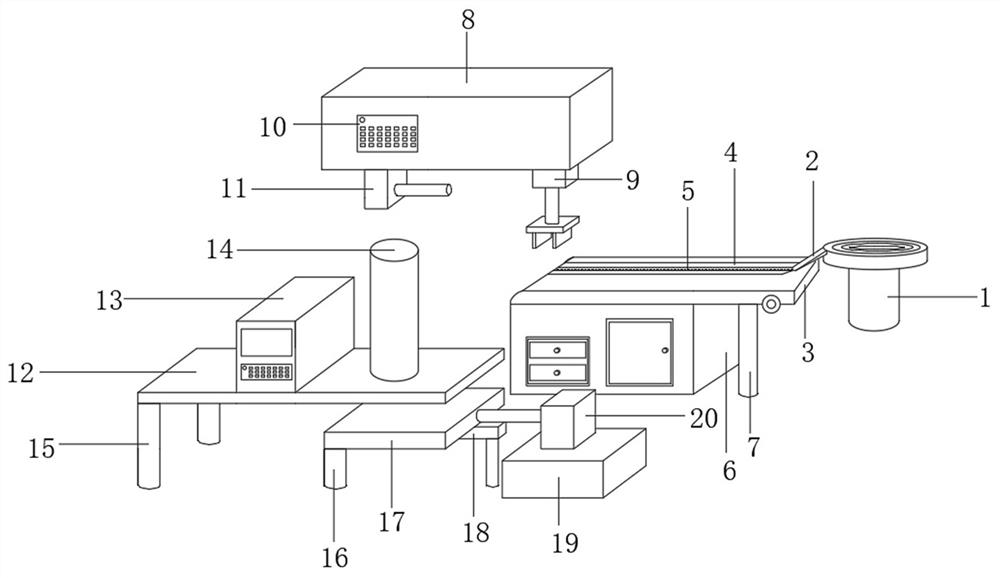

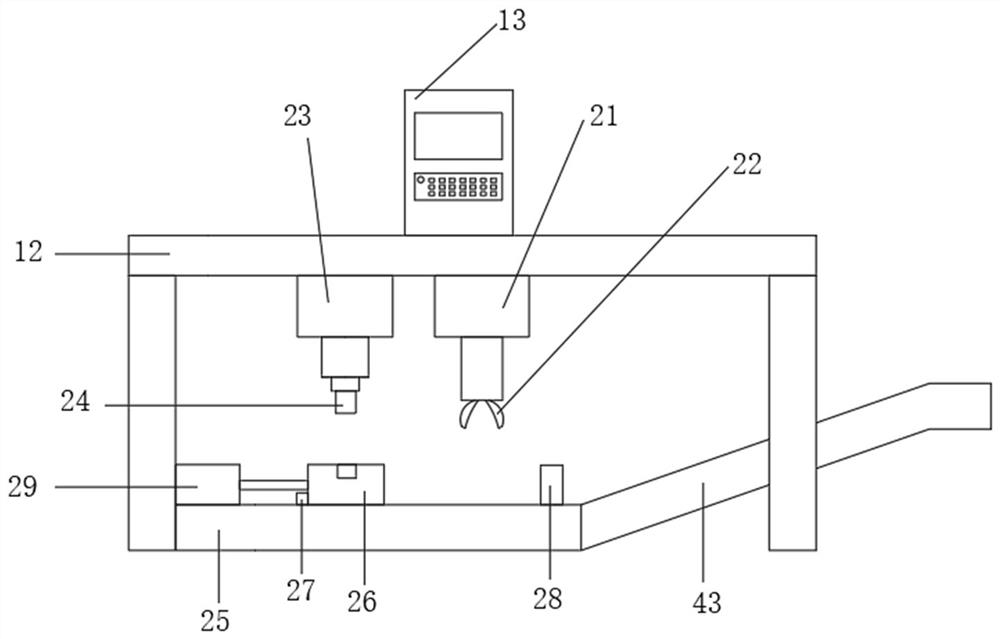

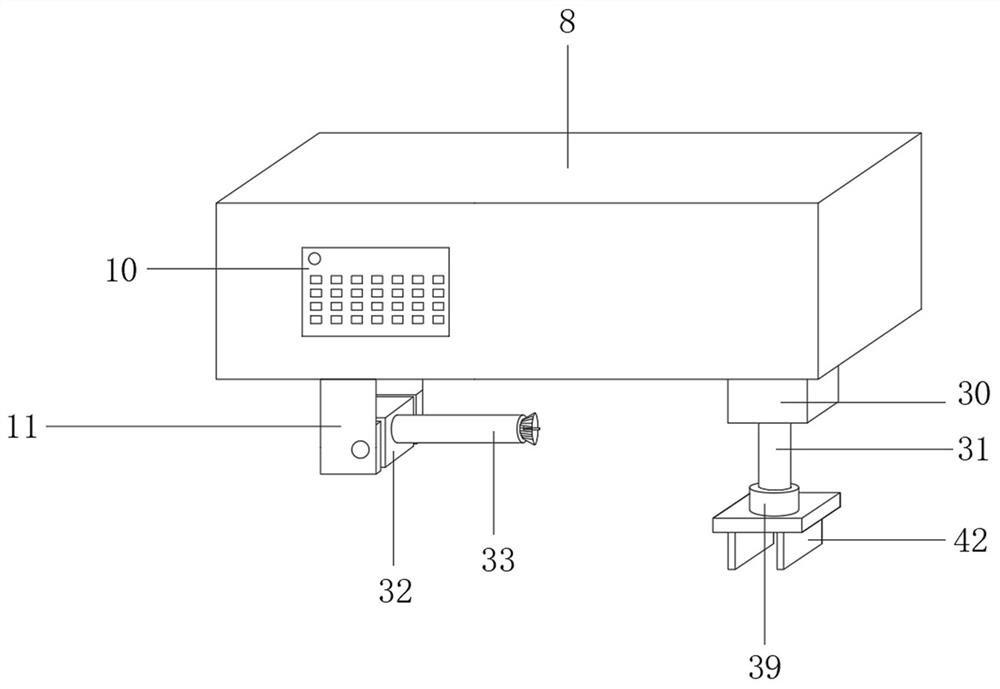

[0027] Such as Figure 1-5As shown, a stamping system of an electronic fuel injection pump includes a feeding vibration plate 1, a first conveying mechanism, a second conveying mechanism, a detection mechanism, and a stamping mechanism. The detection mechanism is guided by a test cylinder 14 and a bottom movable plate 17. , a controller 13, the stamping mechanism is composed of a stamping machine 23, a guide stamping mechanism 24 arranged at the bottom of the stamping machine 23, and the guide stamping mechanism 24 is composed of a movable sleeve 34, a connecting column 35, and a guide column 37. A guide groove 36 is evenly opened on the side of the connecting column 35, and a guide protrusion matching the guide groove 36 is provided on the inner side of the movable sleeve 34, and a threaded strip 38 is fixedly connected to the guide column 37. The pressed springs are vibrated and discharged through the feeding vibrating plate 1, and the springs to be pressed are arranged in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com