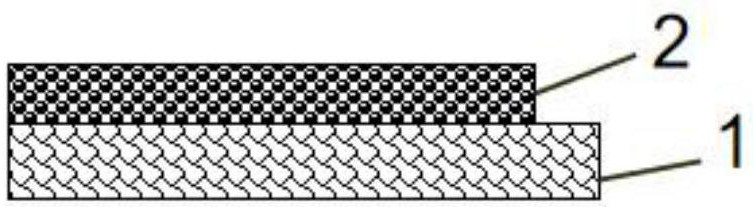

Magnesium metal air battery positive electrode catalyst and continuous coating preparation method thereof

An air battery, magnesium metal technology, applied in battery electrodes, fuel cell type half cells and secondary battery type half cells, fuel cell type half cells and primary cell type half cells, etc., can solve the discharge performance. Poor stability, poor catalyst distribution uniformity, catalyst distribution uniformity, large difference in thickness and structure consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

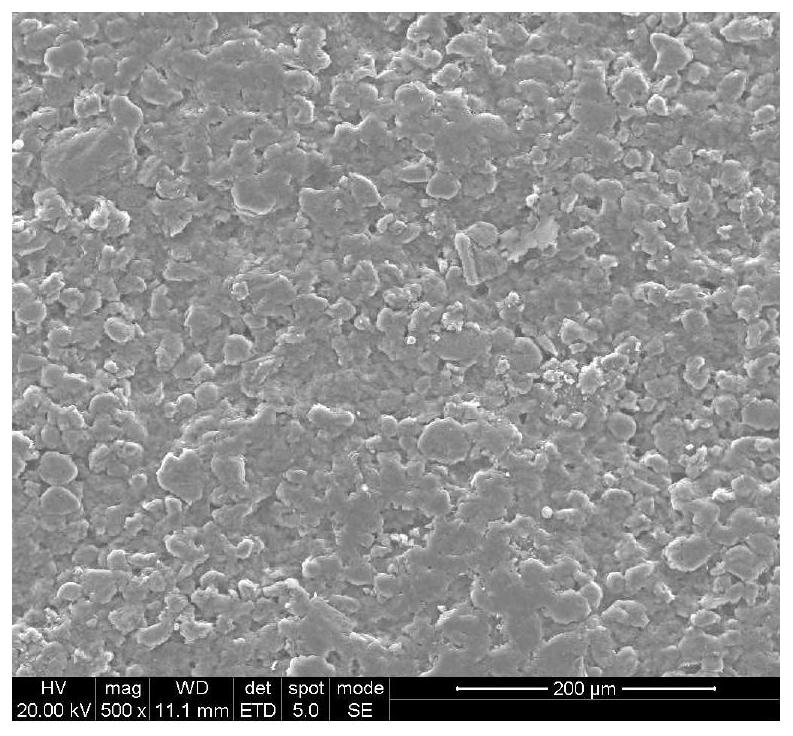

[0046] S1: The conductive material in the selected catalyst is: dense spherical graphite with a powder particle size of 1 μm, porous activated carbon with a particle size of 100 μm, the purity is 99%, and the active material is: powdered manganese-based oxide (MnO2), particle size 1μm, the purity is 99%, the binder is: polytetrafluoroethylene emulsion (PTFE), the solvent is distilled water; the conductive material powder, active material powder, and binder are weighed in proportion, and the proportion is: conductive material spherical Graphite 35%, porous activated carbon 35%, active material MnO 2 20%, binder PTFE10%, the above materials are mixed evenly in a three-dimensional mixer, and the mixing time is 30min to obtain the mixed material.

[0047] S2: add solvent water to described mixed material in proportion, the addition of water accounts for 50% of catalytic slurry, after adding water, stir into uniform slurry in dispersion mixer, stirring speed is at 200 rev / min, stir...

Embodiment 2

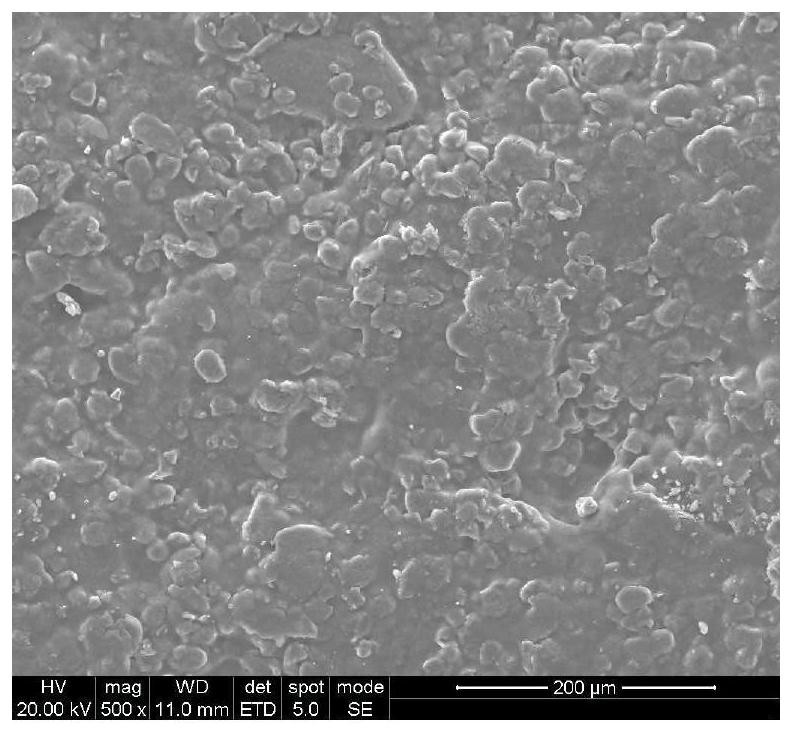

[0053] S1: Select the conductive material in the catalyst to be: dense flake graphite with a powder particle size of 100 μm, carbon black with a particle size of 1 μm, the purity is above 99%, and the active material is: powdered manganese-based oxide (MnO2) with a particle size of 100 μm , the purity is 99%, the binder is: polyvinylidene fluoride (PVDF), the solvent is distilled water; the conductive material powder, active material powder, and binder are weighed in proportion, and the proportion is: conductive material flake graphite 10 %, carbon black 10%, active material (MnO 2 )75%, binder 5%, the above materials are mixed uniformly in the three-dimensional mixer, and the mixing time is 120min to obtain the mixed material

[0054] S2: Add solvent water in proportion to the mixed material, the addition of water accounts for 80% of the catalytic slurry, after adding water, stir into a uniform slurry in a dispersing mixer, the stirring speed is at 3000 rpm, The stirring tim...

Embodiment 3

[0059] S1: The conductive material in the catalyst is selected as follows: dense spherical graphite with a particle size of 10 μm, acetylene black with a particle size of 10 μm, activated carbon with a particle size of 80 μm, and a purity of 99.5%. The active material is: perovskite compound, 20 μm, a purity At 99%, the binder is: polytetrafluoroethylene emulsion (PTFE) and carboxymethyl cellulose (CMC), and the solvent is distilled water; the conductive material powder, the active material powder, and the binder are weighed in proportion and prepared The ratio is: spherical graphite 10%, acetylene black 10%, activated carbon 10%; perovskite compound 20%, binder 50%, mix the above materials evenly in a three-dimensional mixer, and the mixing time is 60min to obtain the mixed material

[0060] S2: Add solvent water in proportion to the mixed material, the amount of water added accounts for 60% of the catalytic slurry, after adding water, stir into a uniform slurry in a dispersin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com