An indirect measurement method for wear of difficult-to-disassemble parts such as high-speed switching valves

A high-speed switching valve and measurement method technology, applied in the field of erosion and wear measurement, can solve the problems of high-speed switching valve structural integrity damage, difficult measurement, etc., to achieve the effect of saving manpower and material resources, saving measurement costs, and avoiding downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

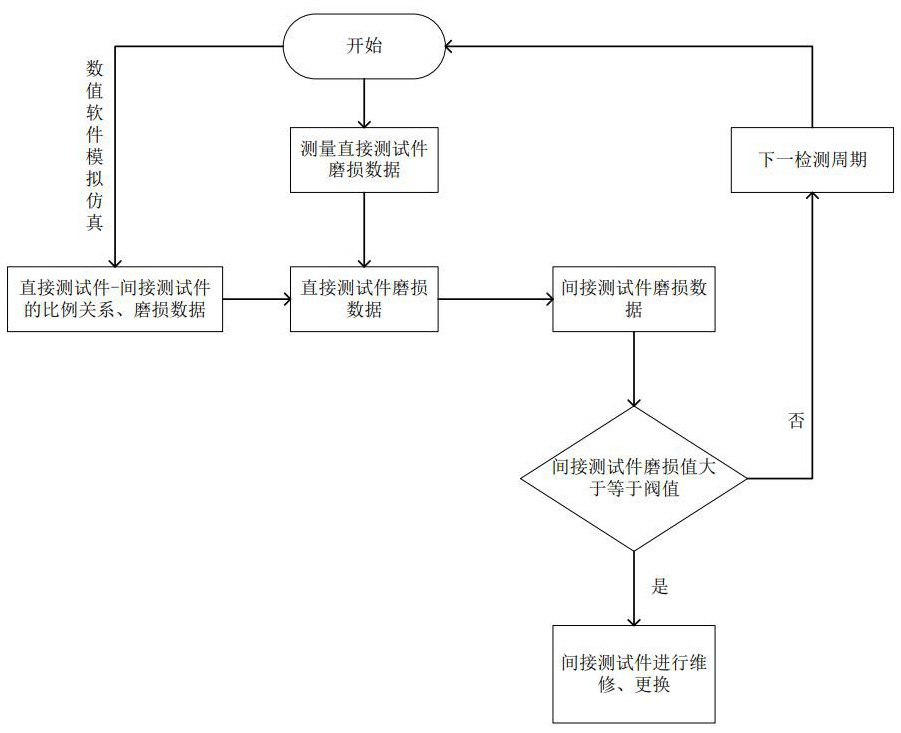

Method used

Image

Examples

Embodiment 1

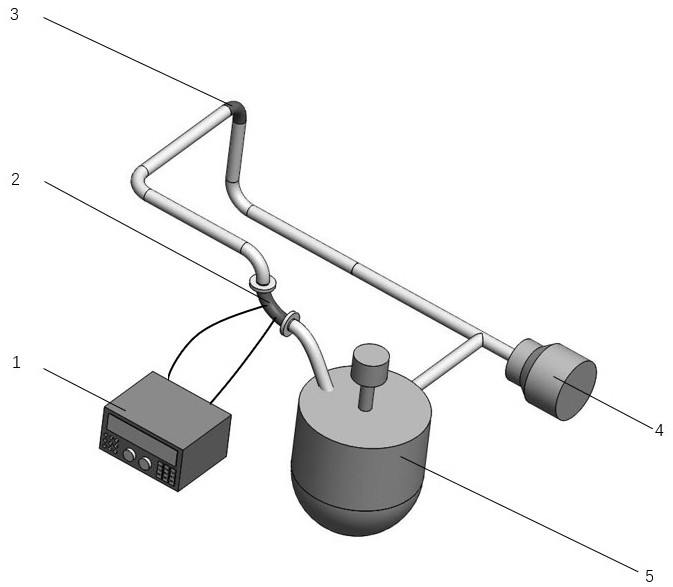

[0038] reference Figure 3 , in the present embodiment, the piping system is a low-voltage or low-density system with low requirements on system containment, including an information acquisition module, an information processing module and other parts by measuring assembly 1. The information acquisition module is responsible for collecting the current value of the resistor in real time, and transmits the collected current value to the information processing module; the information processing module integrates the current information collected by the metal resistance obtained by the information acquisition module, calculates the resistance value using the formula, calculates the remaining thickness of the metal resistance according to the relationship between the thickness of the resistance and the resistance value, and then calculates the thickness loss value of the metal resistance; the display system accepts the thickness loss value of the metal resistance transmitted by the info...

Embodiment 2

[0064] reference Figure 4 , in the present embodiment of the pipeline system is a high voltage or a system with high requirements for system containment, the two ends of the direct test piece need to be connected to an external bypass, as a temporary transport for measurement, and both ends of the bypass circuit, both ends of the direct test piece are provided with valve components.

[0065] When measuring, open two bypass valves 7, and close two main circuit valves 6, the original system through the direct test piece 2 of the transport section to be transported by the bypass, and then the direct test piece 2 from the pipeline system disassembled down, directly using the measurement assembly measurement to obtain its wear value.

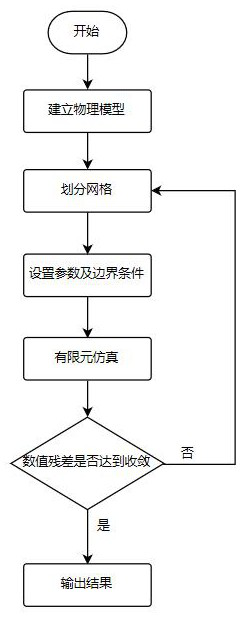

[0066] Establish a physical model of the fluid domain with the same solid structure as the direct test piece 2 and the indirect test piece 3, import it into the numerical simulation software, divide the calculation grid, set the same boundary conditions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com