Piezoresistive sensing fabric with unidirectional moisture transfer function and preparation method thereof

A unidirectional moisture-wicking and conductive fabric technology, which is applied in plant fibers, textiles, papermaking, and material resistance, can solve problems such as poor air permeability and poor wearing comfort, and achieve excellent electrical conductivity, high humidity resistance and high precision , the effect of excellent sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a preparation method of a piezoresistive sensing fabric with unidirectional moisture-conducting effect, comprising the following steps:

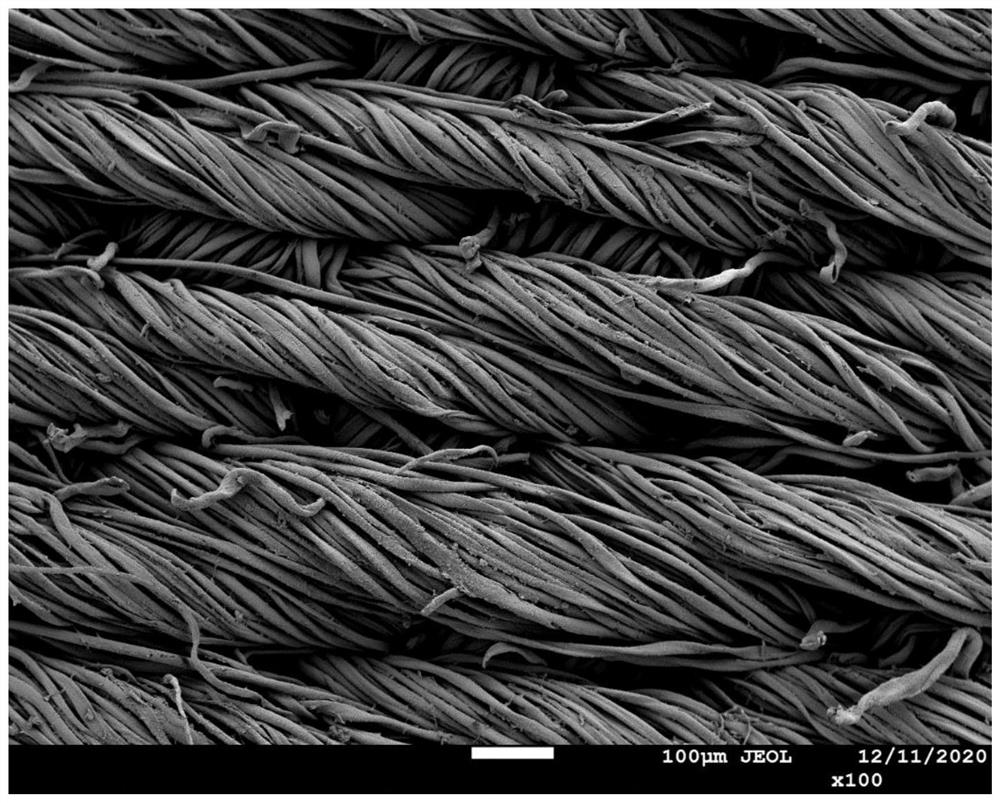

[0037] S1, immerse the pretreated fabric base cloth in a polymer conductive solution, ultrasonically treat it for 1-30 minutes, to obtain a conductive fabric, and then roll the conductive fabric for 3-5 times, and then heat the conductive fabric at 50-120 ° C. Drying for 5-60 minutes, so that the upper and lower surfaces and the inside of the fabric base cloth are uniformly deposited with a loaded polymer conductive layer to obtain a first conductive fabric;

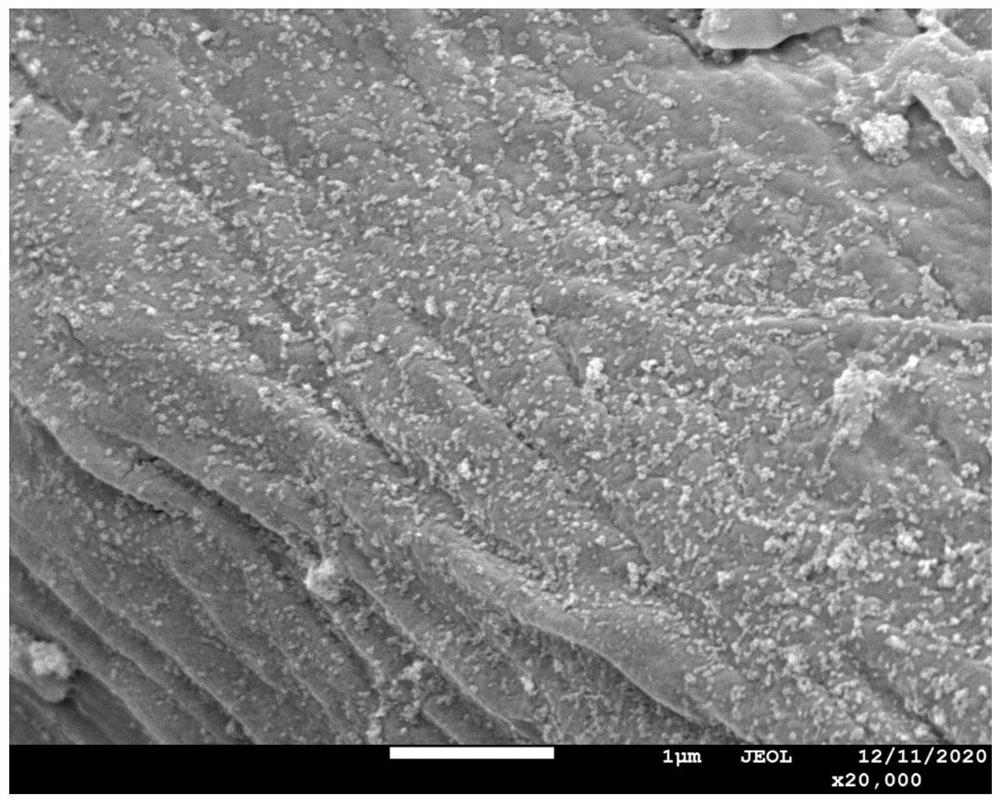

[0038] S2, immersing the first conductive fabric prepared in step S1 in a dispersion of a hydrophobic metal oxide, and ultrasonically treating it for 0.5 to 15 minutes to obtain a hydrophobic conductive fabric; then washing the hydrophobic conductive fabric, and then placing drying at 50-120° C. for 5-60 minutes, so that a hydrophobic metal oxide layer is ...

Embodiment 1

[0049] A preparation method of a piezoresistive sensing fabric with unidirectional moisture-conducting effect, comprising the following steps:

[0050] S1, the cotton fabric base cloth is placed in water, sodium hydroxide solution, and ethanol in turn, ultrasonically cleaned for 5 minutes, and then naturally dried, and the pretreated cotton base cloth is immersed in a polypyrrole polymer conductive with a concentration of 2.0wt%. In the solution, ultrasonically treated for 10 min to obtain a conductive fabric, and then the conductive fabric was subjected to rolling treatment, repeated 3 times, and then dried at 60 ° C for 15 min, so that the upper and lower surfaces and the interior of the fabric base cloth were uniformly deposited and loaded with high load. Molecular conductive layer to obtain a first conductive fabric;

[0051] S2, the first conductive fabric prepared in step S1 is immersed in a dispersion of hydrophobic titanium dioxide with a concentration of 5 mg / mL, and ...

Embodiment 2-4

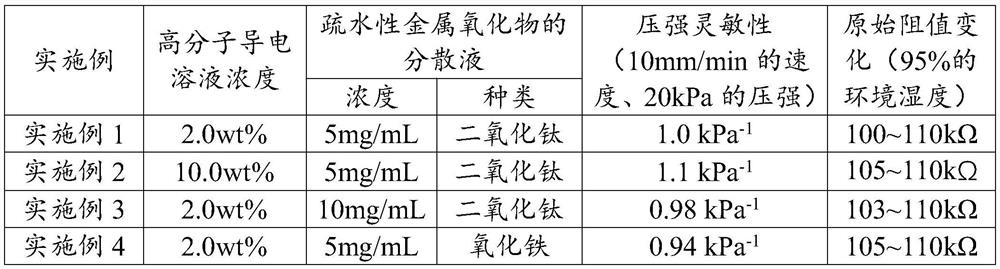

[0085] The difference from Example 1 is that the settings of the implementation parameters in the preparation steps are different, and other steps are the same as those in Example 1, and are not repeated here.

[0086] Table 1 shows the parameter settings in Examples 1 to 4

[0087]

[0088] Combined with Table 1 for analysis:

[0089] 1) In the present invention, the influence of the concentration of the polymer conductive solution on the sensing performance of the piezoresistive sensing fabric is: as the concentration of the conductive solution increases, the resistance of the piezoresistive sensing fabric decreases in a smaller range, and the sensing Sensitivity slightly improved. Considering the cost factor, good sensing performance can be achieved by selecting a moderate concentration of conductive solution.

[0090] 2) The effect of the concentration and type of the dispersion of the hydrophobic metal oxide on the sensing performance of the piezoresistive sensing fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com