Plating solution formula for continuously electroplating satin nickel and process

An electroplating process, the technology of satin nickel, which is applied in the field of electroplating nickel, can solve the problems of insufficient glossiness of the coating, high cost, and many lost working hours, etc., and achieve excellent hydrophobic function, fill porosity, and prevent residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

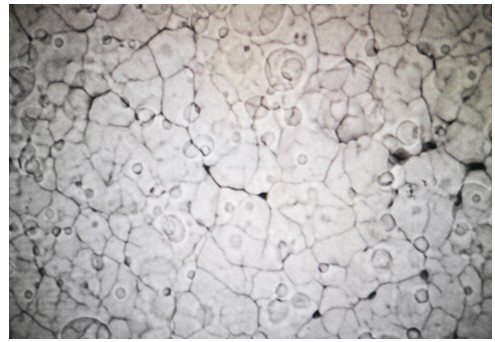

Image

Examples

Embodiment approach 1

[0020] This embodiment provides a formula of satin nickel plating solution, the formula is: nickel sulfate pentahydrate: mass ratio 560 g / l, nickel chloride: mass ratio 30 g / l, boric acid: mass ratio 45 g / l, poly Diethyl alcohol compound: volume ratio 35ml / liter, fatty alcohol polyoxyethylene ester compound: volume ratio 5.0ml / liter, oxyethylene alkylamide compound: volume ratio 1.0ml / liter.

[0021] The process of continuous electroplating satin nickel includes: pretreatment→pre-nickel plating→sardine nickel plating→semi-bright nickel plating→water cutting. Specifically:

[0022] Pre-treatment: Ultrasonic degreasing → electrolytic degreasing, current density 6~10ASD → normal temperature water washing → pickling → normal temperature water washing.

[0023] Pre-plating nickel: current density 8~15ASD, wash with water at room temperature after electroplating for 5~10 seconds.

[0024] Use the above-mentioned satin nickel plating solution formula to plate satin nickel: control ...

Embodiment approach 2

[0029] The continuous electroplating process of satin nickel provided in this embodiment is roughly the same as Embodiment 1, the difference is only that in the satin nickel plating solution formula, the mass ratio of nickel sulfate pentahydrate is 530 grams per liter, polyoxyethylene alkylamide The volume ratio of the compound was 0.9 ml / L.

[0030] In this embodiment, the prepared satin nickel coating is stable and uniform, has no macula, and has a glossiness of 75.

Embodiment approach 3

[0032] The continuous electroplating process of satin nickel provided in this embodiment is roughly the same as Embodiment 1, the only difference is that in the satin nickel plating solution formula, the volume ratio of polydiethanol-based compound is 36ml / L, fatty alcohol polyoxyethylene ester The volume ratio of the compound was 5.5 ml / L, and the volume ratio of the polyoxyethylene alkylamide compound was 1.1 ml / L.

[0033] In this embodiment, the prepared satin nickel coating is stable and uniform, has no macula, and has a glossiness of 50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com