Zinc-germanium oxide long-afterglow luminescent material and preparation method thereof

A technology of long afterglow luminescence and long afterglow materials, which is applied in the direction of luminescent materials, chemical instruments and methods, and can solve the problems of low afterglow intensity and short afterglow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

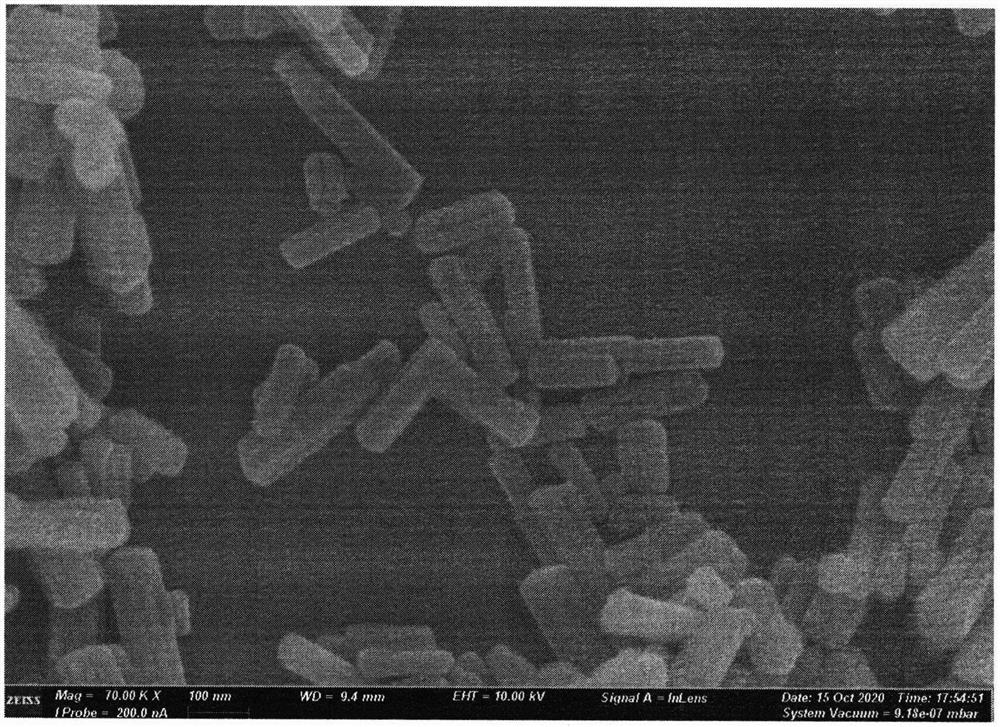

[0018] Example 1: The chemical composition formula of this embodiment is Zn 2 GeO 4 : 0.005Eu 3+ The preparation method of the long afterglow material is as follows:

[0019] Take GeO 2 0.52364g was dissolved in 10mL 3mol / L NaOH solution to prepare Na 2 GeO 3 solution; called Zn(NO 3 ) 2 ·3H 2 O 5.2996g, Eu(NO 3 ) 3 ·6H 2 O 0.0043g was prepared into 100mL solution respectively, 10mL was taken respectively in the same 100mL beaker, 3μL of concentrated nitric acid was added and stirred for 5min, then Na 2 GeO 3 Solution 2mL. Take concentrated ammonia water to adjust the pH to 6.5, continue to stir for 1 hour, put it into a 50mL polytetrafluoroethylene-lined autoclave, put it into an electric blast drying oven, heat it to 220°C for 4 hours, then cool it down to room temperature naturally, and take out the reaction product , after three to four times of high-speed centrifugal washing, put it into an electric blast drying oven to keep warm at 120°C and dry for 12 hours...

example 2

[0021] Example 2: The chemical composition formula of this embodiment is Zn 2 GeO 4 : 0.005Eu 3+ The preparation method of the long afterglow material is as follows:

[0022] Take GeO 2 0.52364g was dissolved in 10mL 3mol / L NaOH solution to prepare Na 2 GeO 3 solution; called Zn(NO 3 ) 2 ·3H 2 O 5.2996g, Eu(NO 3 ) 3 ·6H 2 O 0.0043g was prepared into 100mL solution respectively, 10mL was taken respectively in the same 100mL beaker, 3μL of concentrated nitric acid was added and stirred for 5min, then Na 2 GeO 3 2 mL of solution. Take concentrated ammonia water to adjust the pH to 6.5, continue to stir for 1 hour, put it into a 50mL polytetrafluoroethylene-lined high-pressure reactor, put it into an electric blast drying oven, heat it to 220°C and keep it for 4 hours, then cool it down to room temperature naturally, and take out the reactant After three to four times of high-speed centrifugal washing, put it into an electric blast drying oven to keep warm at 120°C an...

example 3

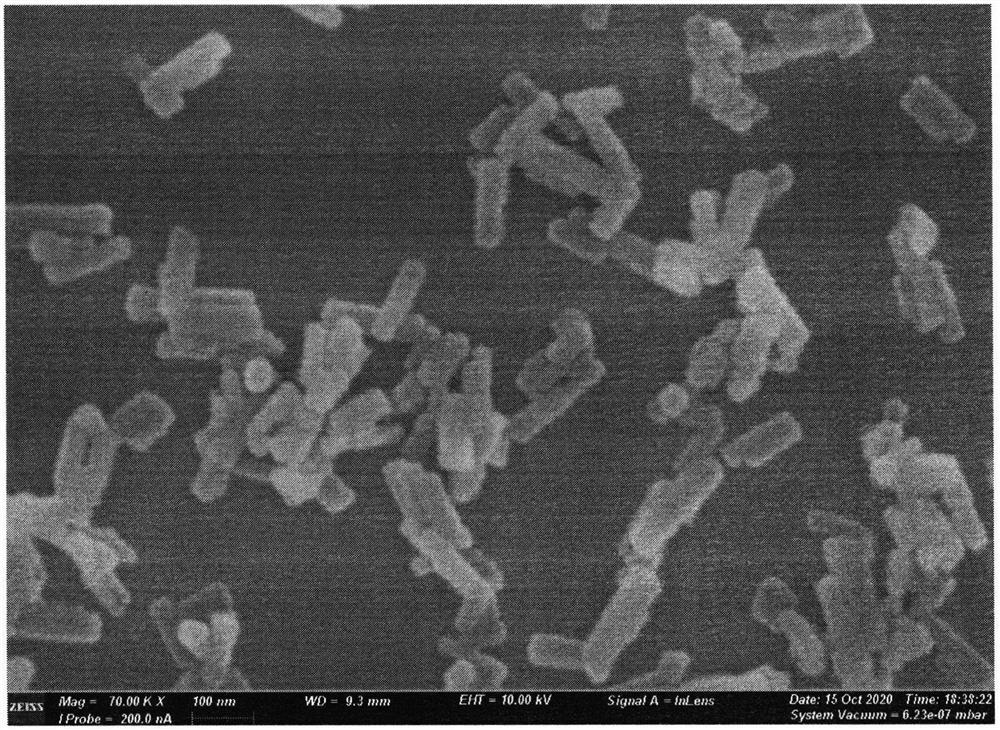

[0024] Example 3: The chemical composition formula of this embodiment is Zn 2 GeO 4 : 0.005Eu 3+ The preparation method of the long afterglow material is as follows:

[0025] Take GeO 2 0.52364g was dissolved in 10mL 3mol / L NaOH solution to prepare Na 2 GeO 3 solution; called Zn(NO 3 ) 2 ·3H 2 O 5.2996g, Eu(NO 3 ) 3 ·6H 2 O 0.0043g was prepared into 100mL solution respectively, 10mL was taken respectively in the same 100mL beaker, 3μL of concentrated nitric acid was added and stirred for 5min, then Na 2 GeO 3 2 mL of solution. Take concentrated ammonia water to adjust the pH to 8.5, continue to stir for 1 hour, put it into a 50mL polytetrafluoroethylene-lined autoclave, put it into an electric blast drying oven, heat it to 220°C for 4 hours, then cool it down to room temperature naturally, and take out the reactant After three to four times of high-speed centrifugal washing, put it into an electric blast drying oven to keep warm at 120°C and dry for 12 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com