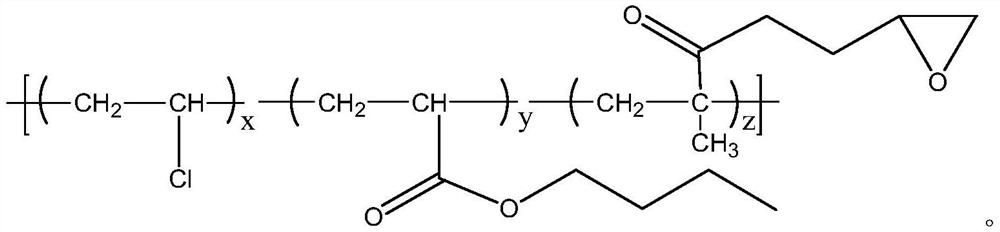

Vinyl chloride acrylate copolymer modified water-based asphalt and preparation method thereof

A technology of copolymer modification and acrylate, which is used in the preparation of new asphalt materials and the preparation of vinyl chloride/acrylate copolymer modified water-based asphalt, can solve the problems of low tensile strength and elongation at break, polluted water quality, etc. , to achieve the effect of high hardness ductility, good weather resistance, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of soap solution:

[0041] The water of 250 grams is heated to 50 ℃, and the vinyl chloride of 25.5g (supplier, Shanghai Mokai Biotechnology Co., Ltd.; purity 0.2mg / mL in MeOH) is added, and the butyl acrylate of 5.1 grams is added successively after stirring and dissolving (supply). Shang, Shanghai Titan; specification, bottle; purity ≥ 99.0%) and 2.55g of glycidyl methacrylate, then add 1.3 g of ammonium persulfate (supplier, Shanghai Titan; specification 19333477 purity ≥ 98%) initiator, and finally Add 6g of sodium dodecyl sulfate (supplier, Shanghai Titan; specification 19333042 purity ≥88.0%) and polyvinyl alcohol (supplier, Shanghai Titan; specification 19333774 1788 type) composite emulsifier, stir and mix at a speed of 300r / min for 10min , and react at 40-50° C. for 4 hours to obtain a vinyl chloride-butyl acrylate-glycidyl methacrylate aqueous emulsion with a viscosity of 3000 mPa.s, that is, a soap solution.

Embodiment 2

[0043] Preparation of maleic anhydride pitch:

[0044] 400g base asphalt is heated to 140-160°C, 2-10wt% maleic anhydride is added based on the weight of the base asphalt, and 1% initiator is added based on the weight of the maleic anhydride, and the mixture is sheared and stirred at 8000r / min. React at 140-160°C for 4-6h to obtain maleic anhydride modified asphalt.

[0045] Table 1 Preparation of different maleic anhydride pitches

[0046] Experiment number Maleic anhydride (g) Ammonium persulfate (g) Softening point (g) 1 8 0.08 48 2 16 0.16 52 3 24 0.24 53 4 32 0.32 56 5 40 0.40 58

Embodiment 3

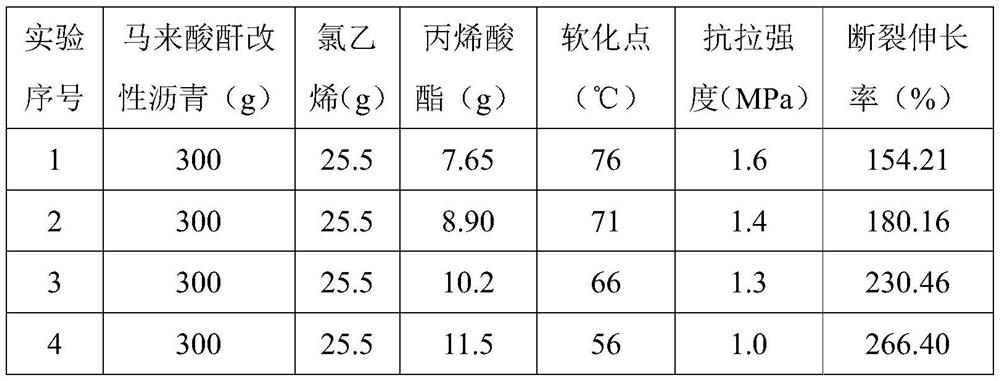

[0048] Preparation of vinyl chloride / acrylate copolymer modified water-based asphalt:

[0049] The maleic anhydride pitch obtained in experiment number 3 in Example 2 was added to the soap solution obtained in Example 1, and then a drier with an emulsion weight of 0.1-3wt% was added, and sheared for 15min at a rotating speed of 8000r / min, The vinyl chloride / acrylate copolymer modified water-based asphalt in the emulsion state is obtained.

[0050] Table 2 Performance comparison of prepared products of various vinyl chloride / acrylate copolymer modified water-based asphalts

[0051]

[0052] It can be seen from Table 1 that when the maleic anhydride pitch is prepared, the softening point increases with the increase of the maleic anhydride pitch content.

[0053] It can be seen from Table 2 that the asphalt product of the present invention has a tensile strength of more than 1 MPa, and an elongation at break of more than 150%, and has relatively high mechanical properties. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com