Pipeline injection type pressurized mixed chemical agent automatic injection control device

A chemical agent, injection technology, applied in mixers, chemical instruments and methods, pipeline systems, etc., can solve the problems of high cost of high-pressure metering pumps, inability to automatically modify the concentration of agents online in time, etc., to achieve on-site and remote automatic monitoring. , The effect of high degree of automation of the device and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

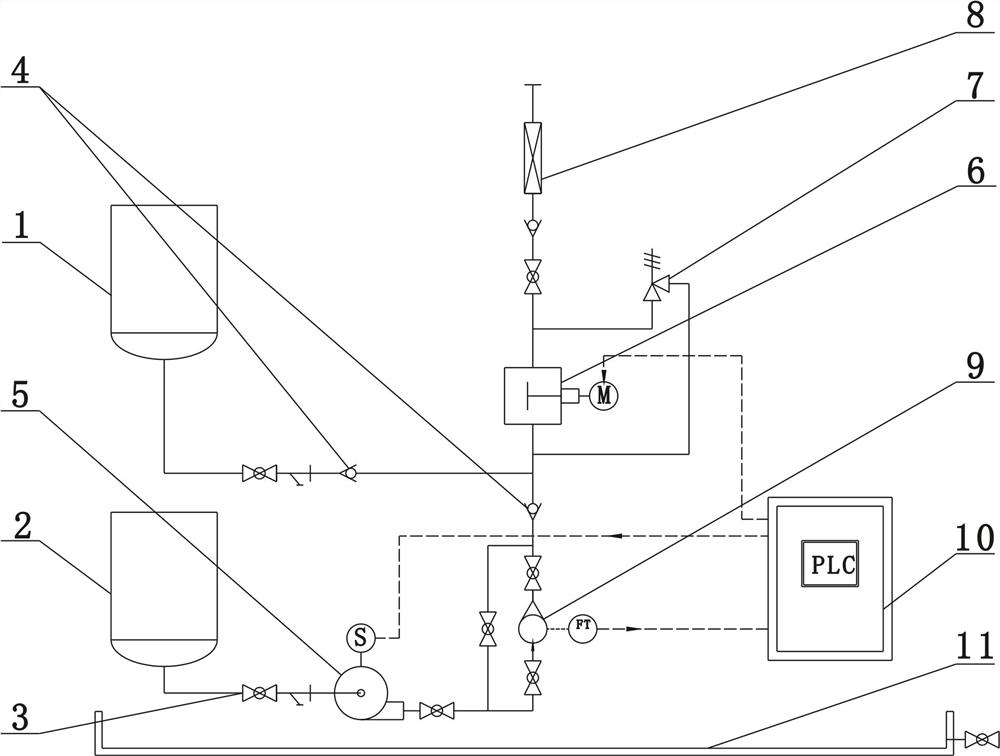

[0017] combined with figure 1 Describe in detail a pipeline injection pressurized mixed chemical agent automatic injection control device of the present invention, including a mother liquor tank 1, a chemical agent tank 2, a low-pressure flow-regulating electromagnetic pump 5, a high-pressure filling diaphragm pump 6, a mixer 8, an online flow rate Meter 9 and PLC automatic control box 10, mother liquid tank 1 and chemical agent tank 2 are respectively fixed side by side on the same elevation plane through the lower legs, mother liquid tank 1 is used to temporarily store the mother liquid from the process pipeline, and the outlet of mother liquid tank 1 The liquid port is connected to the inlet of the high-pressure filling diaphragm pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com