Red mud harmless treatment system based on circulating fluidized bed boiler and its working method

A circulating fluidized bed and harmless treatment technology, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of iron oxide and aluminum oxide not being effectively used, polluting the environment, etc., and achieve the realization of Social and economic benefits, wide fuel adaptability, and easy utilization of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

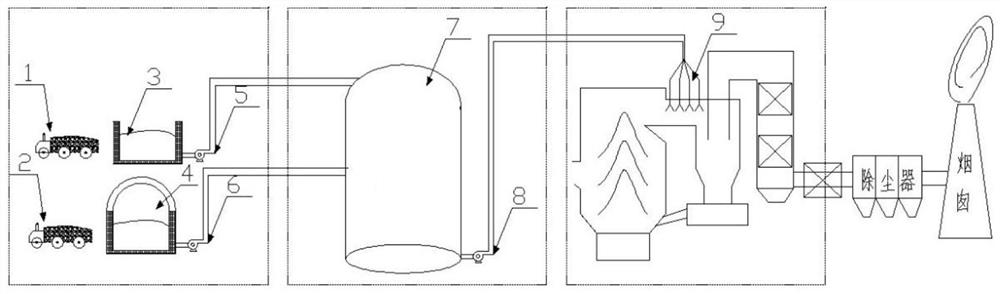

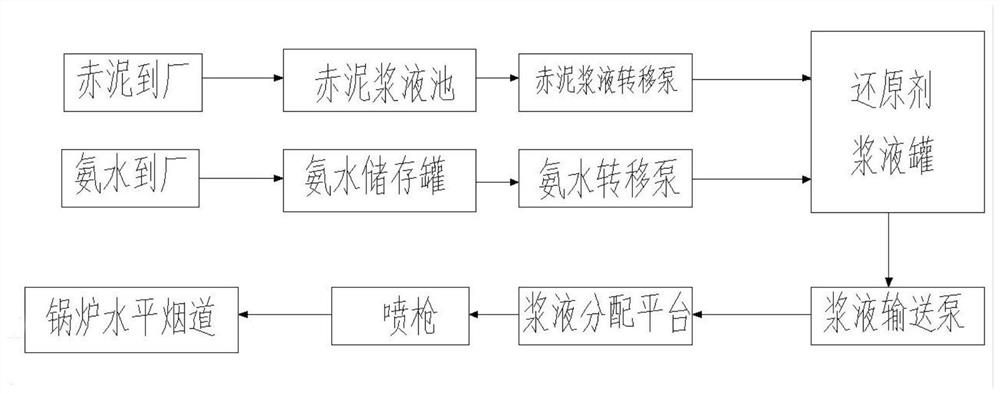

[0041] Such as figure 1 , is a red mud harmless treatment system based on a circulating fluidized bed boiler of the present invention, including a red mud slurry dissolution tank 3, an ammonia water storage tank 4, a reducing agent slurry tank 7, a reducing agent slurry delivery system 8 and a reducing agent slurry injection system9.

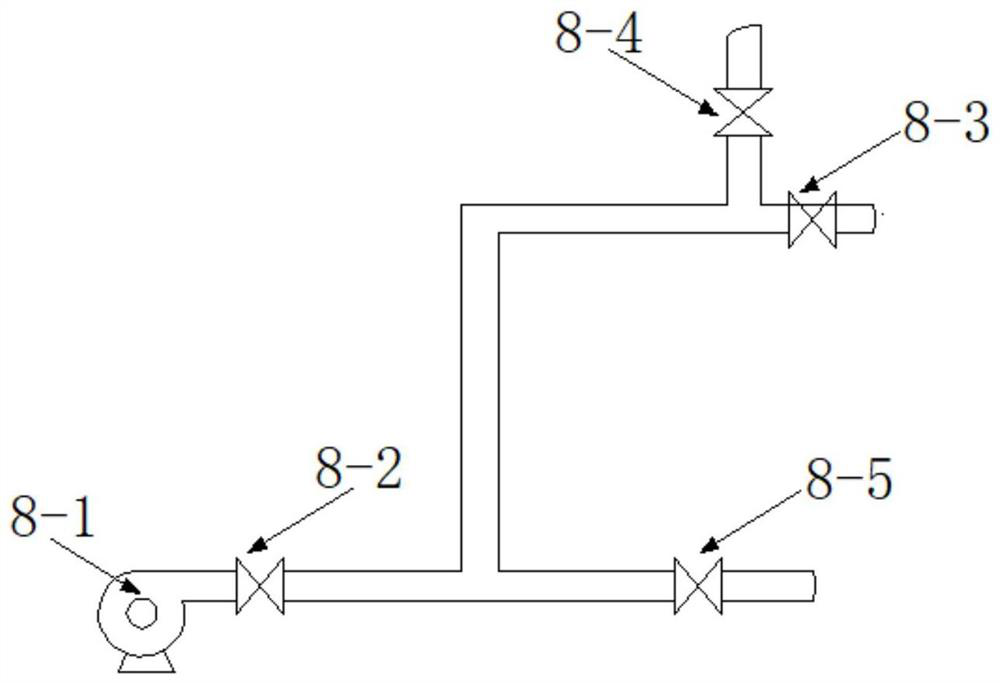

[0042] Such as Figure 4 , The reducing agent slurry tank 7 is provided with a monitoring instrument 7-4, a reducing agent slurry outlet, a red mud slurry inlet and an ammonia water inlet, and the monitoring instrument 7-4 includes a thermometer, a pressure gauge, a density gauge and a visual liquid level gauge. The reducing agent slurry tank 7 is provided with a slurry tank heating device 7-1 and a slurry tank agitator 7-2, and the slurry tank agitator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com