{111} crystal face highly-exposed titanium dioxide efficient photoelectrode and preparation and application thereof

A {111}, titanium dioxide technology, applied in the field of high-efficiency titanium dioxide photoelectrodes, to achieve good dispersion and firmness, improved safety factor, and wide light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

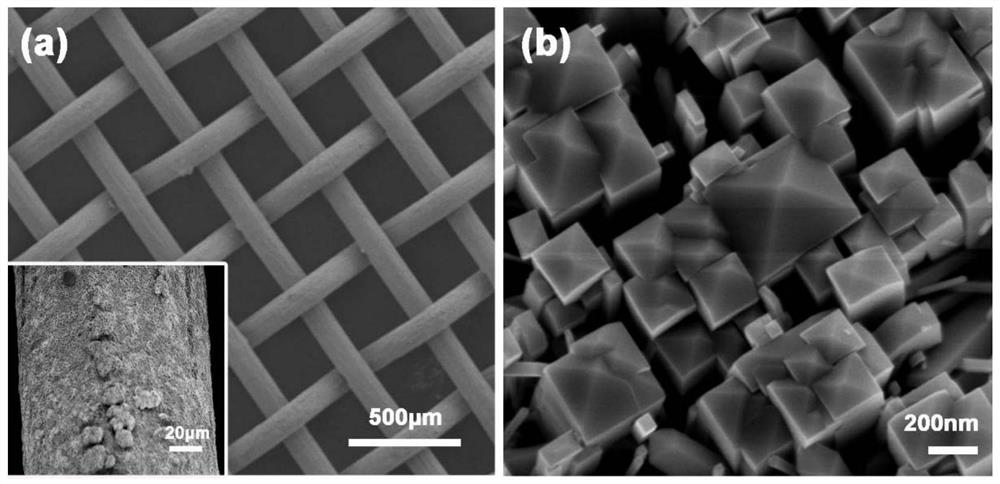

[0037] A kind of rutile TiO 2 The preparation method of / Ti photoelectrode specifically comprises the following steps:

[0038] (1) Cut the titanium mesh into a size of 4.5cm×7cm, fold it into double layers along the long side, and put it in a mixture of hydrochloric acid and water (hydrochloric acid: water volume ratio 1:1, the concentration of hydrochloric acid used here is 36-38%) ) for chemical polishing, followed by ultrasonic cleaning with deionized water and absolute ethanol for 3 times after 5 min, and stored in absolute ethanol for later use.

[0039] (2) Dry the chemically polished titanium mesh in step (1), and calcine it in an air atmosphere with a heating rate of 3°C / min, a calcination temperature of 700°C, and a calcination time of 3h to obtain rutile TiO 2 / Ti photoelectrode.

Embodiment 2

[0041] A {111} TiO with Highly Exposed {111} Facets 2 The preparation method of / Ti photoelectrode specifically comprises the following steps:

[0042] (1) Cut the titanium mesh into a size of 4.5cm×7cm, fold it into double layers along the long side, and put it in a mixed acid solution containing nitric acid, hydrofluoric acid and water (nitric acid: hydrofluoric acid: water volume ratio 5:1:25) ) for chemical polishing, took it out after 30 s, and cleaned it with deionized water and absolute ethanol by ultrasonic vibration for three times, and finally stored it in absolute ethanol for later use.

[0043] (2) Mix 1.9mL hydrochloric acid (mass fraction 36-38%), 450μL hydrogen peroxide (mass fraction 30%) and 7.65mL deionized water, stir evenly, transfer to a 150mL autoclave lining, put For a self-made ring-shaped polytetrafluoroethylene support, lay the double-layer titanium mesh that has been chemically polished in step (1) above the support, at a distance of 6.0 cm from the ...

Embodiment 3~ Embodiment 4

[0047] Compared with Example 2, most of them are the same, except in this example: in the specific process of titanium mesh polishing treatment, the volume ratios of nitric acid, hydrofluoric acid and water forming the polishing solution are respectively 5:1:20 and 5:1:30.

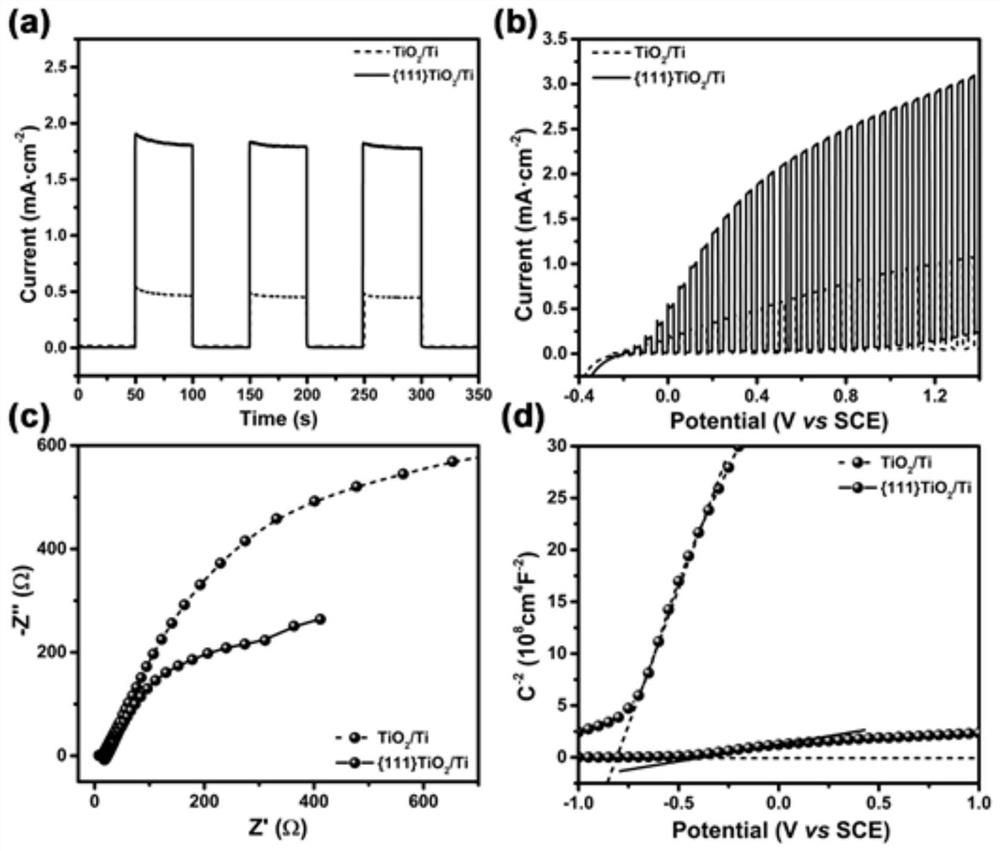

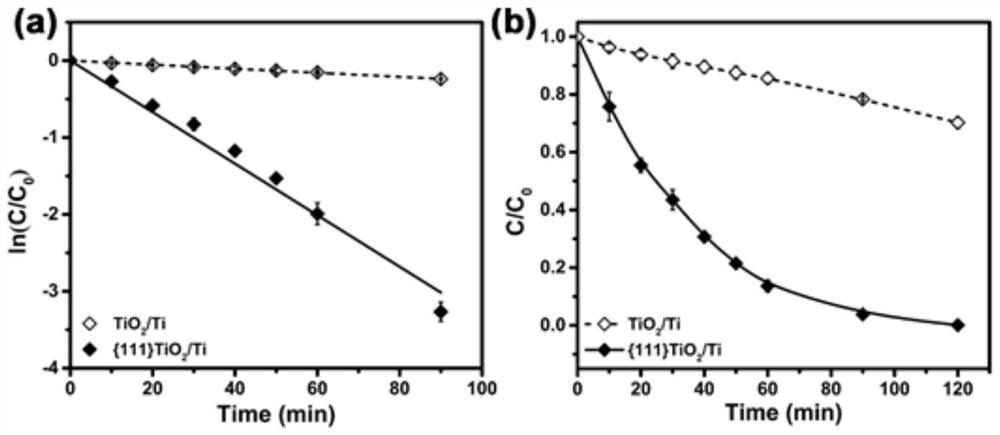

PUM

| Property | Measurement | Unit |

|---|---|---|

| Photocurrent density | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com