Device and method for simultaneously processing multiple planar optical parts

A technology of optical parts and processing devices, which is applied in metal processing equipment, optical surface grinders, manufacturing tools, etc., can solve the problems of high-precision planar optical parts, such as difficulty in processing, low efficiency, and inability to process products with wedge-shaped parts, etc., to achieve Achieve the effects of repeated use, saving the cost of auxiliary materials, and saving the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

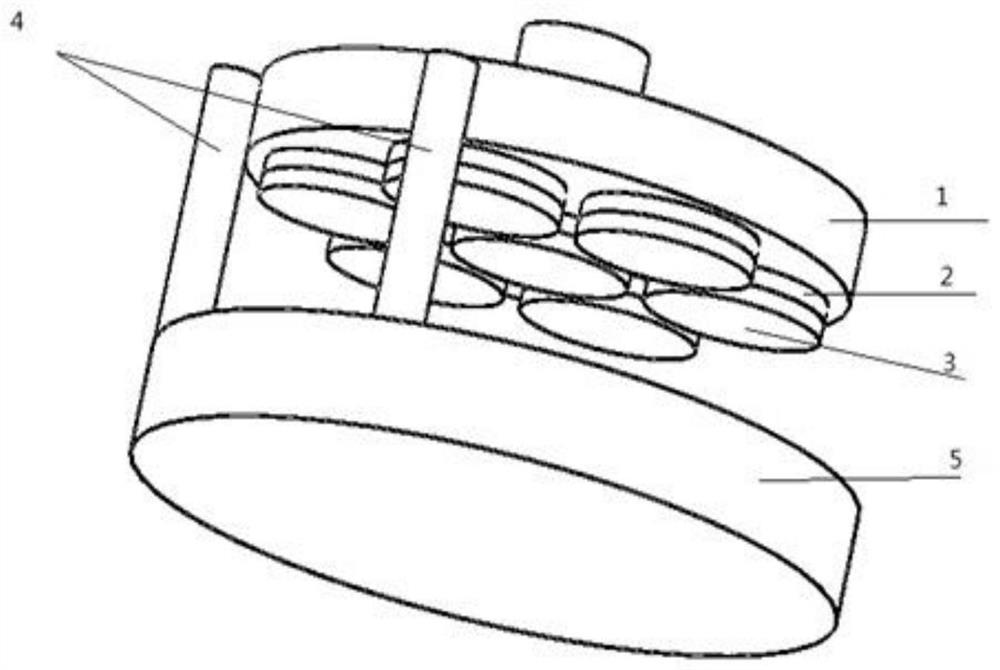

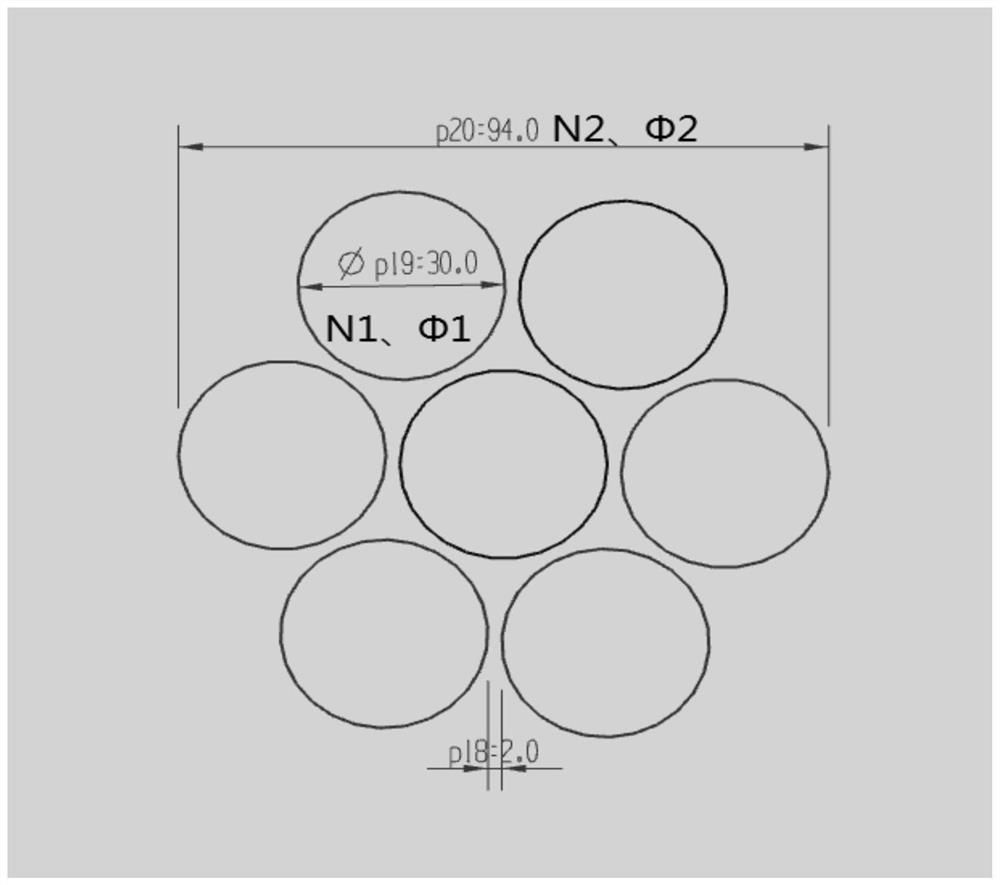

[0026] Such as figure 1 As shown, the multi-piece planar optical parts simultaneous processing device of the present invention includes a polishing machine, a base mold 5 and a bonding mold 1, the bonding mold 1 is connected to the polishing machine, the base mold 5 is arranged on the bottom of the bonding mold 1, and the base The edge of the mold 5 is fixedly connected with two fixed columns 4 perpendicular to the base mold, and the two fixed columns form an angle of 30° to 175° with the central point of the base mold. An optical part 3, the fixed column designed by the present invention can locate the relative position between the optical part and the bonding mold, ensure that the parts will not be displaced after bonding, and ensure that the parts are evenly distributed in the center of the mold.

[0027] The specific processing steps are as follows:

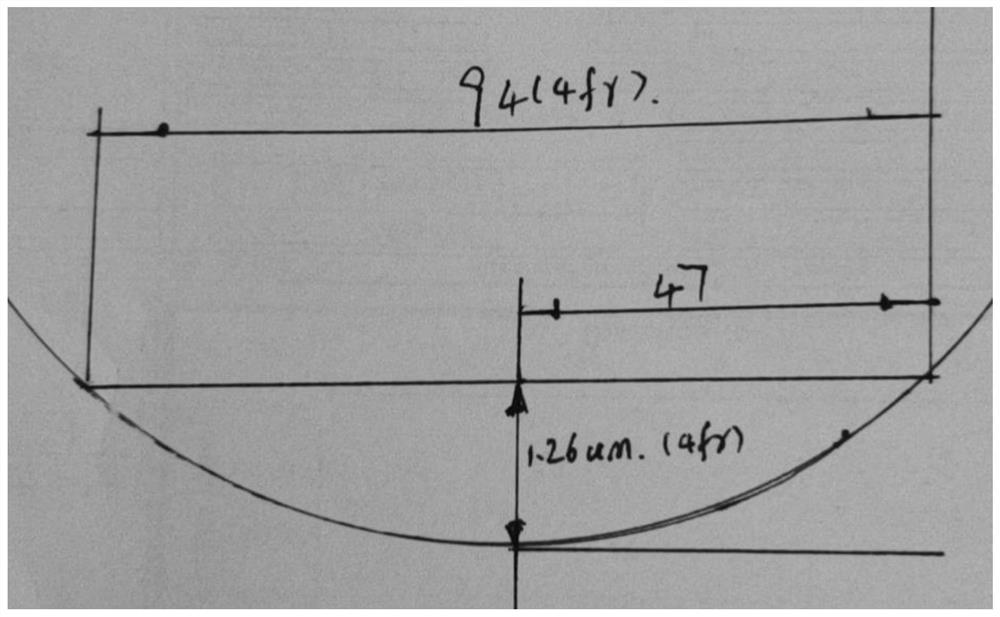

[0028] 1. The production of the base mold. The requirements of the base mold are that the aperture of the bonding surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com