Aluminum alloy drawing type friction plug repair welding joint and machining method thereof

An aluminum alloy, drawing-type technology, applied in the field of welding manufacturing, can solve the problems of non-welding and weak bonding of the interface between the stopper rod and the base metal, and achieve the effect of eliminating welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technology and method of the present invention will be described in detail below in conjunction with the examples and accompanying drawings. The following examples and accompanying drawings are used to illustrate the composition of the present invention, but are not intended to limit the scope of the present invention.

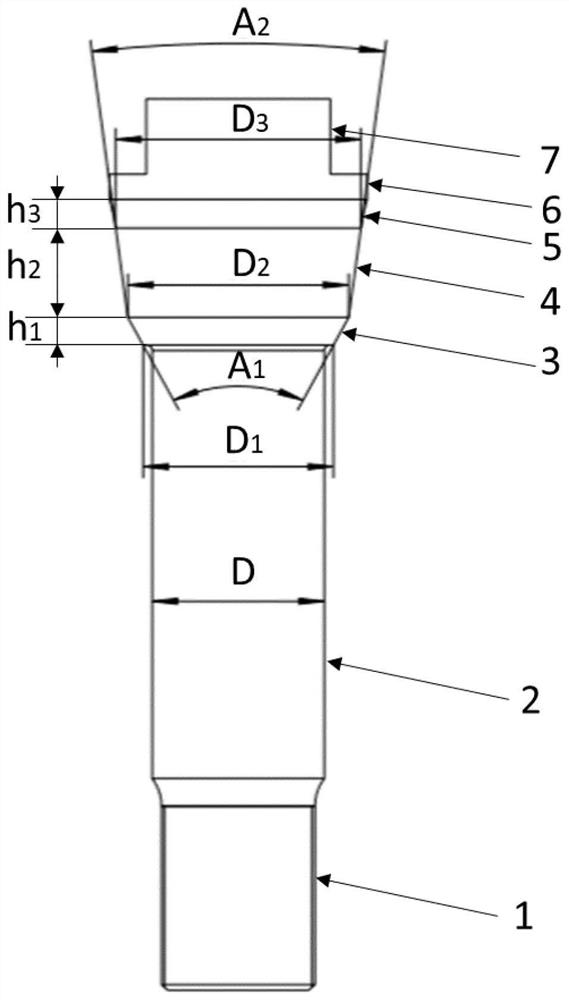

[0034] The present invention provides the design of stopper rod geometric dimension, as figure 1 shown. The stopper rod mainly includes: connecting thread (1), positioning section (2), transition section (3), welding section (4), arc section (5), parallel section (6), clamping handle (7) and other parts . The stopper thread section (1) is used for the connection between the stopper rod and the tool handle, and bears axial tension and torque during the welding process; the stopper rod positioning section (2) is used for the axis positioning of the stopper rod to ensure that the stopper rod and the repair welding hole concentricity; the stopper rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com