A stamping plate butt welding device

A welding device and butt welding technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of insufficient stamping and high production costs, achieve good welding effects, facilitate welding defects, and eliminate welding defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with the accompanying drawings:

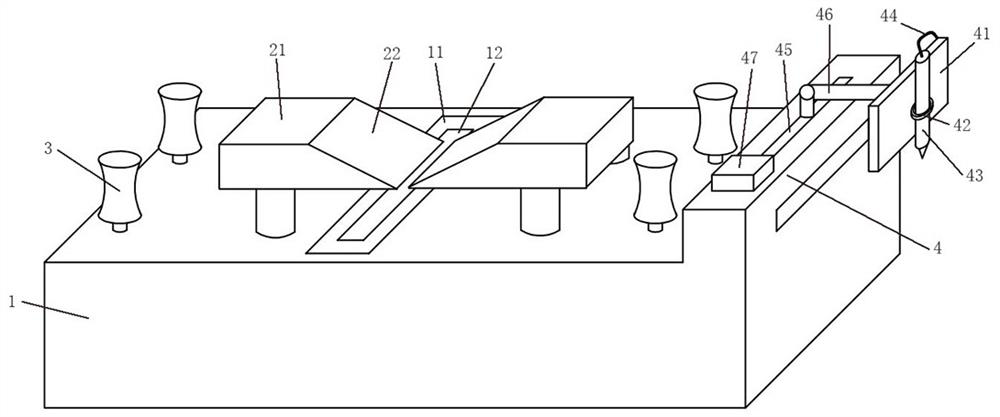

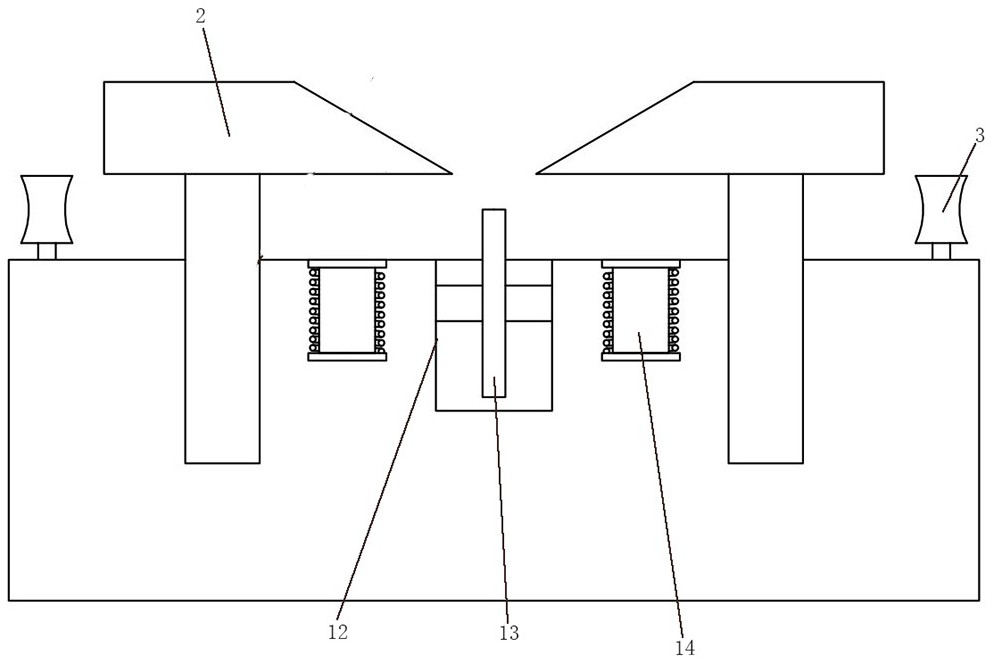

[0030] like figure 1 , 2 As shown in the figure, a butt welding device for stamping plate parts includes a welding platform 1, a pair of pressure plates 2 and a pair of limit posts 3 symmetrically arranged at the transverse ends of the welding platform 1, and a welding plate mounted on one side of the welding platform 1. device 4. The limit column 3 includes a pair of guide wheels placed on the welding platform 1 transversely opposite; the pressure plate 2 includes a rectangular base body 21 and a wedge-shaped pressure block 22 extending outward from one side of the base body 21. The pressing blocks 22 of the pair of pressing plates 2 face each other.

[0031] In this embodiment, the welding device 4 includes a mounting plate 41 located on one side of the welding platform 1 , a mounting ring 42 welded on the mounting plate 41 , and a welding torch 43 sleeved in the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com