Catalyst for preparing isononanoic acid through catalytic oxidation of isononyl alcohol as well as preparation method and application thereof

A technology of catalytic oxidation and isononanol, applied in catalyst activation/preparation, preparation of organic compounds, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of poor thermal stability, acid and alkali resistance, etc., Achieving the effect of simple preparation method and good catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Vector pretreatment

[0037] Weigh 5g of activated carbon, disperse in 100ml of 8wt% nitric acid solution, place in 90°C oil bath, stir, condense and reflux for 3h. Then use deionized water to centrifuge and wash several times until the supernatant is neutral in acidity and alkalinity. Finally, under the condition of 55° C., vacuum drying was performed for 12 hours to obtain a pretreated modified activated carbon carrier.

Embodiment 2

[0039] Preparation of Pd-Co / C

[0040] Weigh 8.2mg of palladium chloride, add a small amount of concentrated hydrochloric acid dropwise until completely dissolved; weigh 6.8mg of cobalt chloride hexahydrate, dissolve in a small amount of deionized water, then add chloropalladium acid solution, mix well and add deionized water Dilute to 20ml. Weigh 0.1 g of modified activated carbon, add it to the above solution, and stir at room temperature for 3 h. The pH value of the solution was adjusted to 9-10 with saturated sodium carbonate solution, followed by stirring for 1 h. Weigh 25mg of sodium borohydride, add 10ml of water to dissolve, quickly drop into the above solution, and continue to stir for 3h. Filter the above system through a filter and wash it several times until the filtrate is neutral in acidity and alkalinity, put it in a drying oven at 40°C, and dry it in vacuum for 12 hours to obtain the catalyst Pd-Co / C.

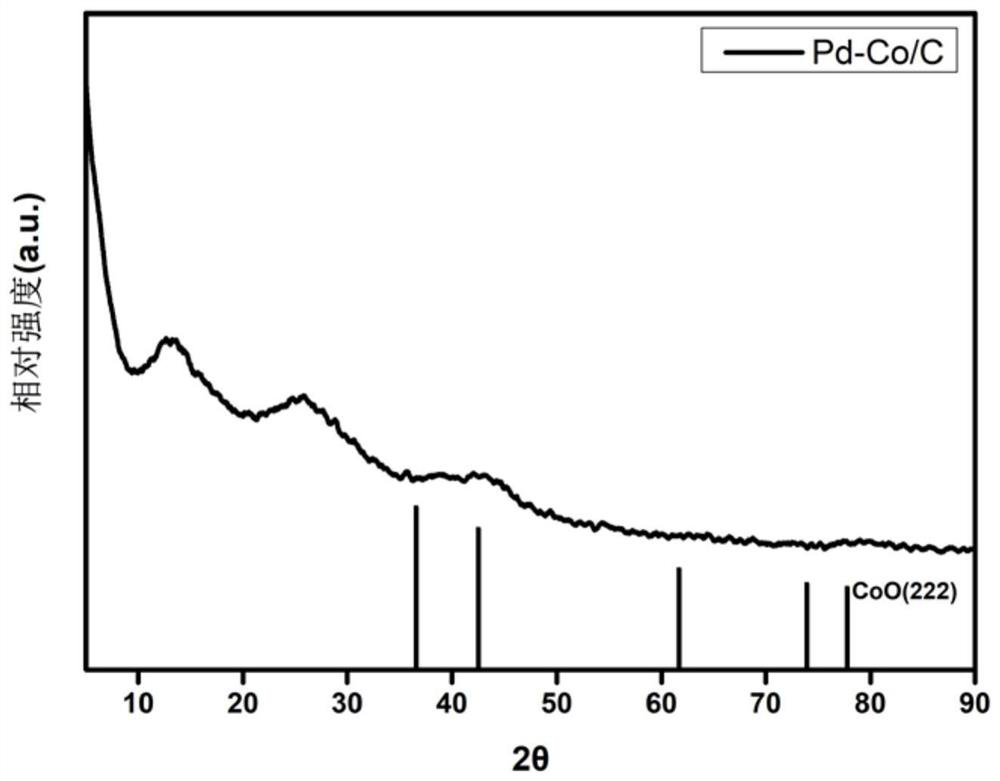

[0041] figure 1 It is the XRD spectrum of the prepared...

Embodiment 3

[0043] Preparation of Pd-Cu / C

[0044] Weigh 8.2mg of palladium chloride, add a small amount of concentrated hydrochloric acid dropwise until completely dissolved; weigh 4.8mg of copper chloride dihydrate, dissolve it in a small amount of deionized water, then add it to the chloropalladium acid solution, mix well and then add deionized Dilute to 20ml with water. Weigh 0.1 g of modified activated carbon, add it to the above solution, and stir at room temperature for 3 h. The pH value of the solution was adjusted to 9-10 with saturated sodium carbonate solution, followed by stirring for 1 h. Weigh 25mg of sodium borohydride, add 10ml of water to dissolve, quickly drop into the above solution, and continue to stir for 3h. Filter the above system through a filter and wash it several times until the filtrate is neutral in acidity and alkalinity, put it in a 40°C drying oven, and dry it in vacuum for 12 hours to obtain the catalyst Pd-Cu / C.

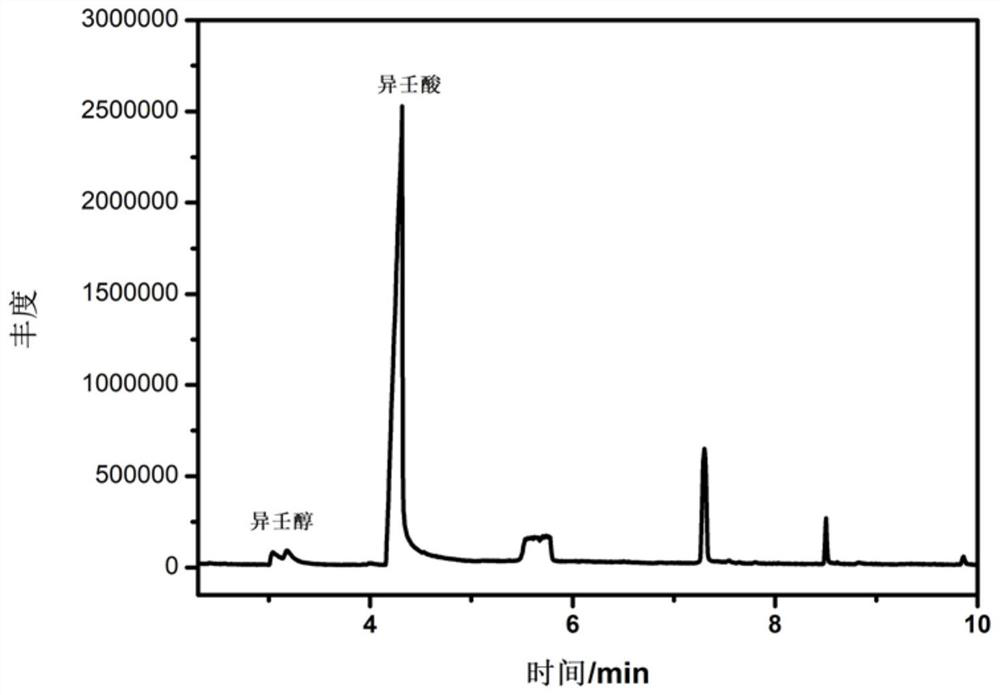

[0045] figure 2It is the XRD spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com