Coal-electricity internal heat circulation system and method for improving wind power consumption level thereof

A circulation system and heat storage system technology, applied in the field of power dispatching, can solve the problems of less research on the flexibility of conventional coal-fired power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

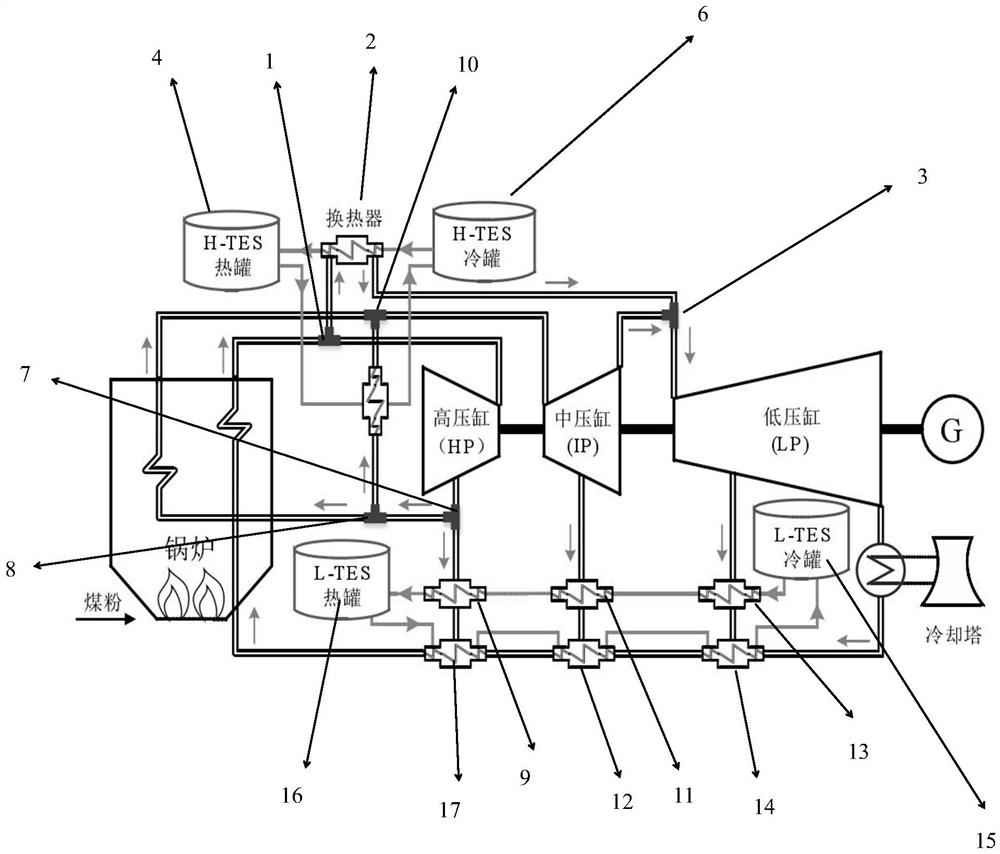

[0066] like figure 1 As shown, a coal-fired internal thermal cycle system includes a steam power generation system, a boiler system, a high-pressure cylinder, a medium-pressure cylinder, a low-pressure cylinder, a cooling tower, and also includes a high-temperature heat storage system and a low-temperature heat storage system;

[0067] The first gas outlet of the boiler system is connected to the first port of the No. 1 tee 1, and the second port of the No. 1 tee 1 is connected to the heat medium inlet of the No. 1 heat exchanger 2 in the high-temperature heat storage system. The heat medium outlet of the No. 1 heat exchanger 2 is connected to the first port of the No. 5 tee 3, and the cold medium outlet of the No. 1 heat exchanger 2 is connected to the air inlet of the hot tank 4 in the high-temperature heat storage system, so The gas outlet of the hot tank 4 in the high-temperature heat storage system is connected through the heat medium inlet of the No. The air outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com