Method for determining material parameters of crystal plasticity finite element model

A technology of crystal plasticity and material parameters, applied in computer material science, electrical digital data processing, special data processing applications, etc., can solve problems such as low precision, many iterations, and poor convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

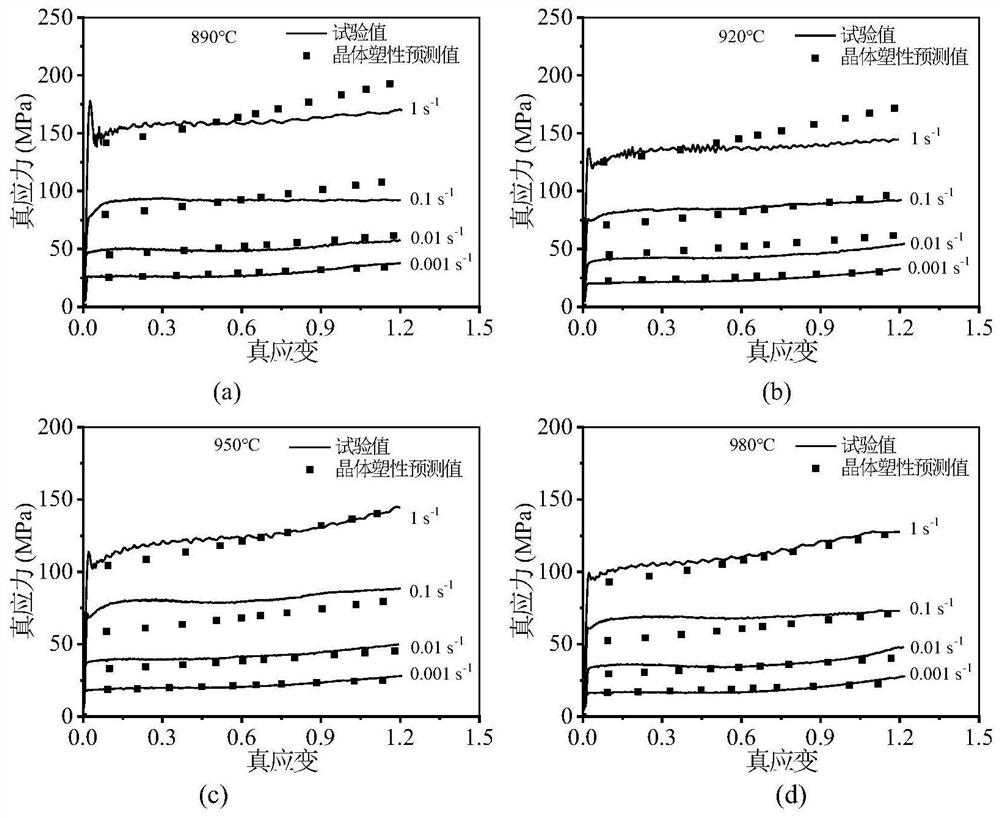

[0020] The present invention is a kind of method that can obtain crystal plasticity finite element material parameter rapidly, below in conjunction with the establishment process of the crystal plasticity finite element model of TC18 titanium alloy as an example, introduces the specific implementation details of the present invention in detail, and its method comprises:

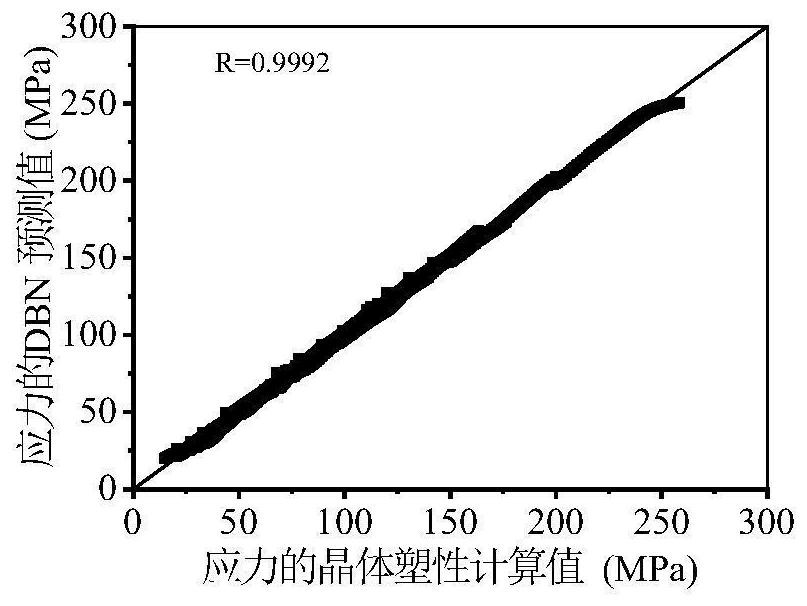

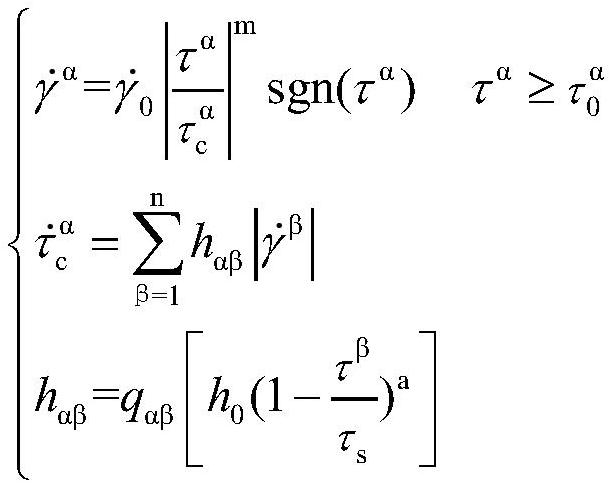

[0021] Step 1: Set different material parameter combinations A, material parameter combination A is shown in Table 1, perform crystal plastic finite element calculations, and obtain true stress and true strain under different parameters; the crystal plastic finite element model described in this step is the only Phenomenological power-law model:

[0022]

[0023] In the formula: is the shear strain rate of the αth slip system, is the reference shear strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com