Antistatic and antibacterial textile fabric and preparation method thereof

A textile fabric, antistatic technology, applied in conductive/antistatic filament manufacturing, textile and papermaking, biochemical fiber treatment, etc. Sol, low production efficiency of textile fabrics, etc., to achieve the effect of increasing antistatic effect, improving antibacterial effect, and efficient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An antistatic and antibacterial textile fabric includes an inner layer fabric and an outer layer fabric, and the inner layer fabric is an antistatic fabric;

[0030] Wherein, this antistatic and antibacterial textile fabric is prepared by the following steps:

[0031] Step 1: Adhere the inner layer fabric and the outer layer fabric with an adhesive to obtain a basic fabric;

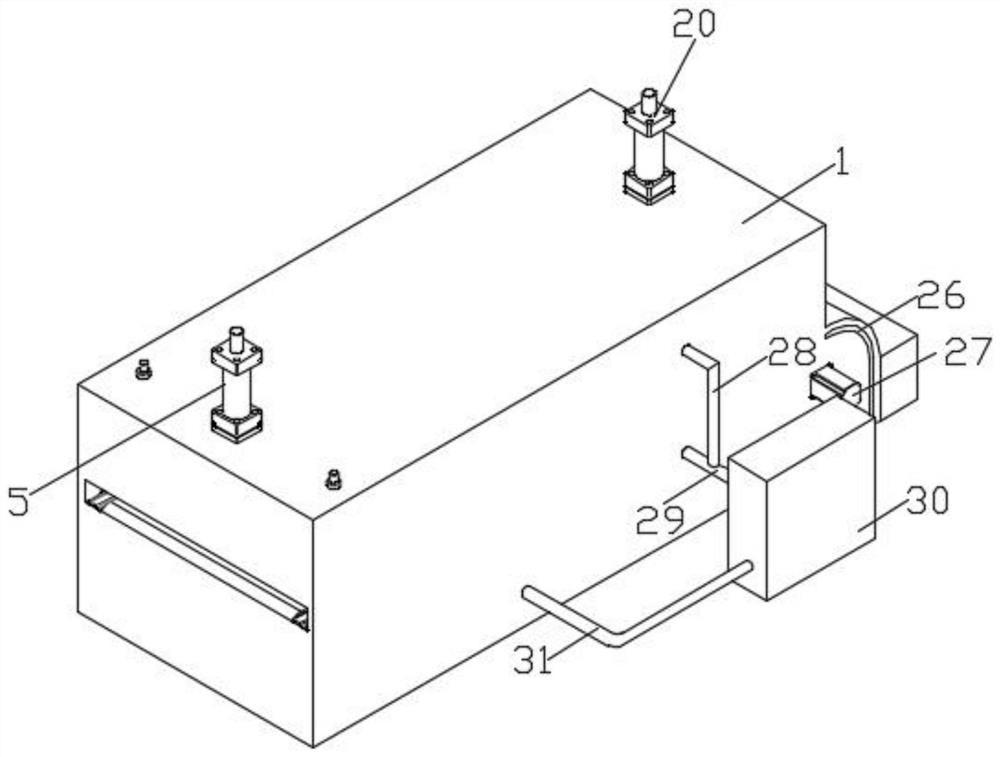

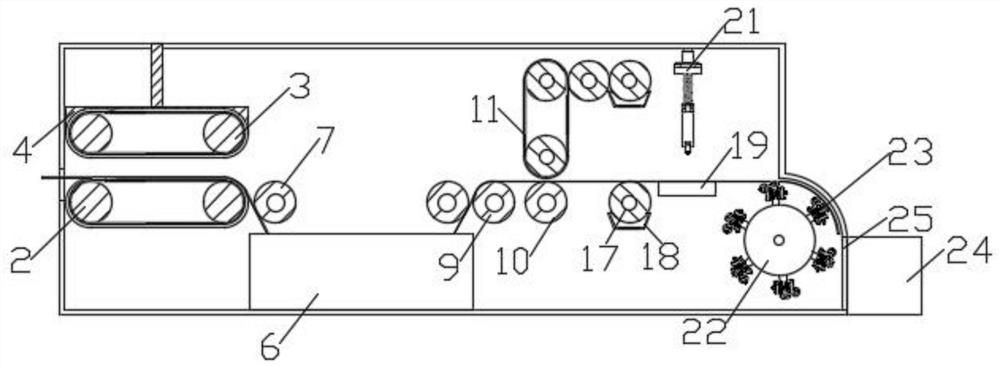

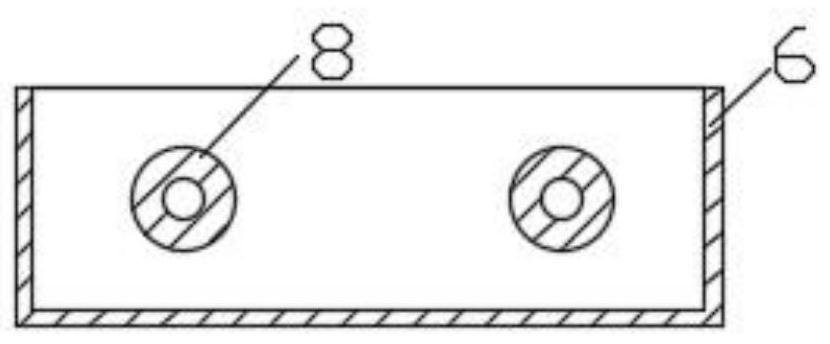

[0032] Step 2: Add the composite hydrosol into the dyeing tank 6 of the dyeing equipment, the pump 30 extracts the composite hydrosol through the rubber suction pipe 31, and transports the composite hydrosol to the upper sol through the first communication pipe 28 and the second communication pipe 29 respectively. In the tank 16 and the lower sol tank 18, put the basic fabric on the first belt conveyor 2, open the first cylinder 5, the piston rod of the first cylinder 5 pushes the lifting shell 4 downward, and the lifting shell 4 drives the second belt conveyor 3 descends, the belts on the first b...

Embodiment 2

[0036] The composite hydrosol in step 2 is prepared by the following steps: S1, by weight, weigh 15 parts of isopropanol, 6 parts of nano-zinc oxide, 11 parts of polyethylene glycol, and 150 parts of water, and weigh the isopropanol by weight. , nano-zinc oxide and polyethylene glycol are dissolved in water, and then mixed with glacial acetic acid in a volume ratio of 1:2.5 to obtain a composite acetic acid solution; S2, 10 parts by weight of cellulose are dissolved in the composite acetic acid solution to obtain cellulose acetate solution solution, and then 5 parts by weight of AgNO 3 Dissolving into the cellulose acetate solution to obtain a cellulose-silver composite antibacterial solution; S3, adding 90 parts by weight of ethyl orthosilicate to the cellulose-silver composite antibacterial solution under high-speed stirring, stirring with a magnetic stirrer for 3 hours at room temperature, A composite hydrosol is obtained. The antistatic fabric is prepared by the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com