Manufacturing method of agricultural cold-proof cloth

A production method and technology of cold-proof cloth, applied in non-woven fabrics, melt spinning, stretch spinning, etc., can solve problems affecting crop growth, affecting soil structure, environmental pollution, etc., to improve usability and service life, The production process is simple and the production cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

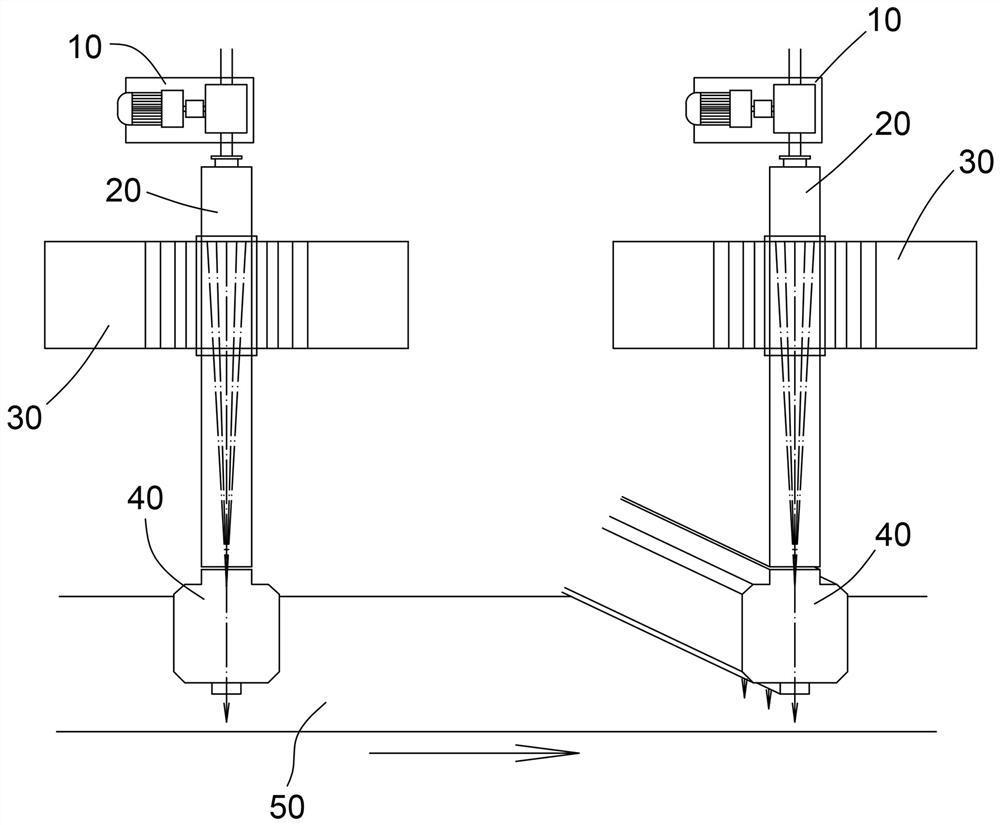

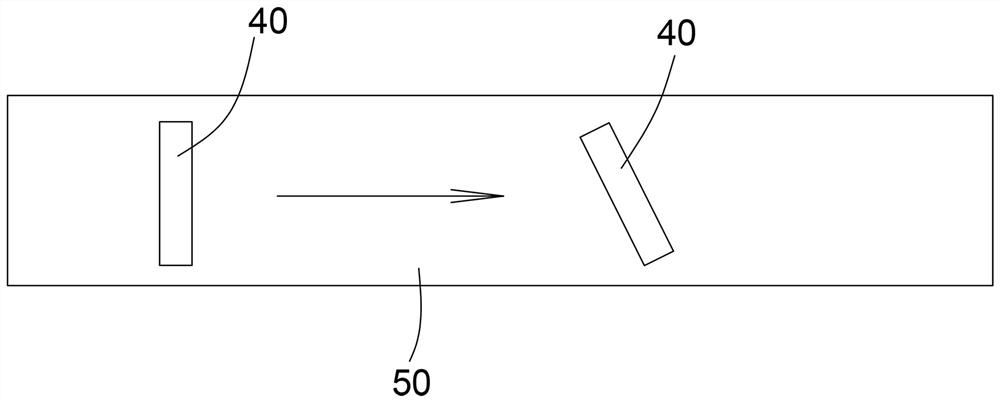

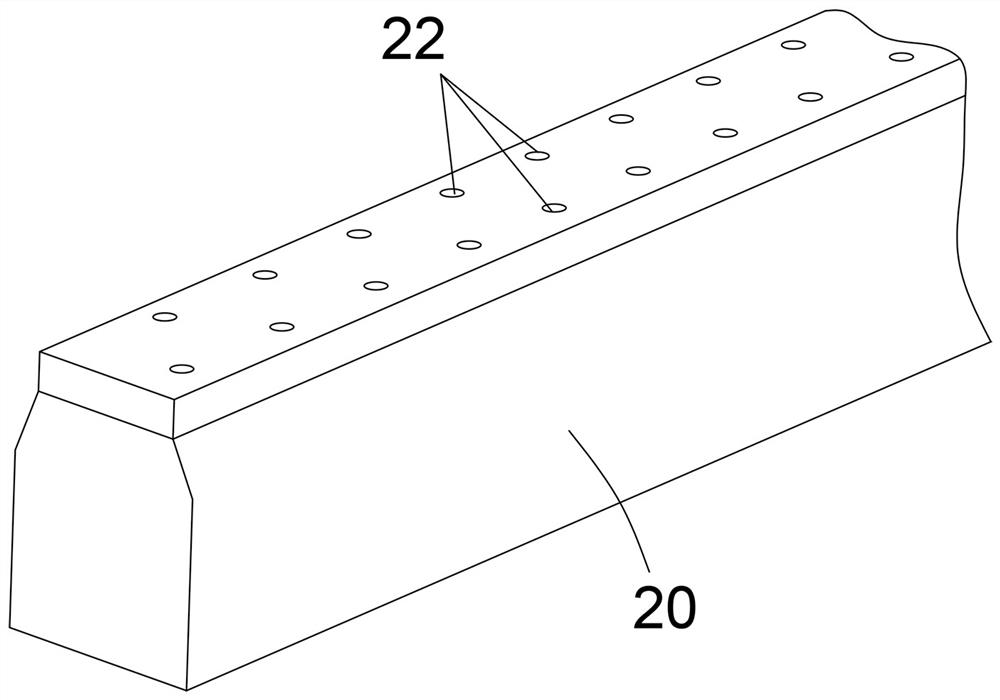

Method used

Image

Examples

Embodiment 1

[0033] Mix 85% of PP base resin, 15% of polyvinylidene fluoride, and 4% of MAH-g-PP compatibilizer in a high-speed blender in proportion, then melt and blend through a twin-screw extruder, and extrude The material is made into masterbatches through a granulator, and the cut masterbatches are dried in an oven for later use. Then, after fully mixing the above-mentioned prepared masterbatch with 3% color masterbatch and 3% anti-aging additive in a plastic mixer in proportion, the material is pumped into the screw extruder through a vacuum suction machine at 230 Melted into a melt at ℃, then extruded by a screw extruder at a speed of 33r / min into a 150-mesh filter to filter out impurities, then sent to a gear metering pump, and then sent to the spinneret through a gear metering pump, melted The temperature of the melt is kept at 180°C, and the melt is sprayed out from the nozzle under its own gravity to form filaments, cooled by the air-conditioning cold air, stretched, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com