Fluffy chinlon filament and preparation method thereof

A nylon and filament technology, applied in the field of textile and chemical fiber, can solve the problems of low modulus and poor resilience of nylon fiber, and achieve the effect of good bulkiness, uniform wire diameter and less long pile loops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

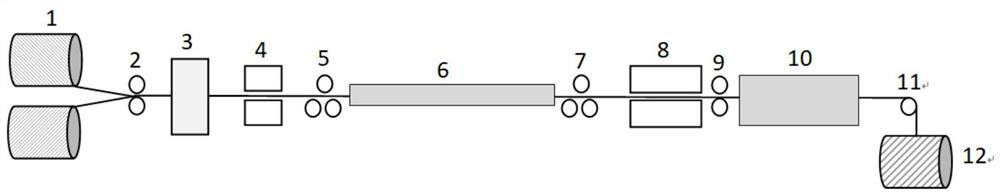

[0026] Such as figure 1 Shown, a kind of preparation method of fluffy nylon filament comprises the following steps:

[0027] S1. Two or more nylon filaments with different dry heat shrinkage rates are transported from the nylon yarn tube 1 to the twister 3 through the first wire feed roller 2 for combined twisting, and the nylon filaments with different dry heat shrinkage rates are combined and twisted. The filaments are wrapped together so that the low-shrinkage nylon wraps the high-shrinkage nylon in a spiral shape, wherein the difference in dry heat shrinkage between the nylon filaments is not less than 10%;

[0028] S2. Adding a network to the twisted nylon filament through the network nozzle 4, so that the two ends of the nylon filament of a certain length are relatively fixed, wherein the number of network nodes per meter is 20 to 200;

[0029] S3. Transport the networked nylon filaments to the first hot box 6 for treatment through the second wire feed roller 5, and ove...

Embodiment 1

[0035] 1. Combining and twisting nylon raw material A and raw material B, the number of twists per 10 cm is 30, wherein, nylon raw material A is 150D / 72f PA6 FDY (its dry heat shrinkage rate is 5%), and nylon raw material B is 30D / 12f PA6 FDY ( dry its heat shrinkage rate 40%);

[0036] 2. Send the twisted nylon filament to the network nozzle to add network, and the number of network nodes per meter is 100;

[0037] 3. Send the nylon filaments added to the network to the first hot box for pre-shrinking at an overfeed of 40%, the temperature is 170°C, and the time is 5-10s;

[0038] 4. Deform the pre-shrunk nylon filaments with an overfeed of 20% to the air deformation nozzle, and the air pressure is 0.8MPa;

[0039] 5. Send the air-deformed nylon filament to the second hot box for shaping, the temperature is 150°C, and the time is 60s;

[0040] 6. Apply oil through the oil guide, and keep low tension during the oiling process;

[0041] 7. Wind the oiled nylon filament into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com