Preparation method of a solid oxide electrolytic cell ternary composite anode

A solid oxide, ternary composite technology, applied in the field of electrolytic cells, can solve the problems of affecting anode oxygen reduction performance and porosity reduction, and achieve the effects of improving electrolytic cell performance, low cost, and improving catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

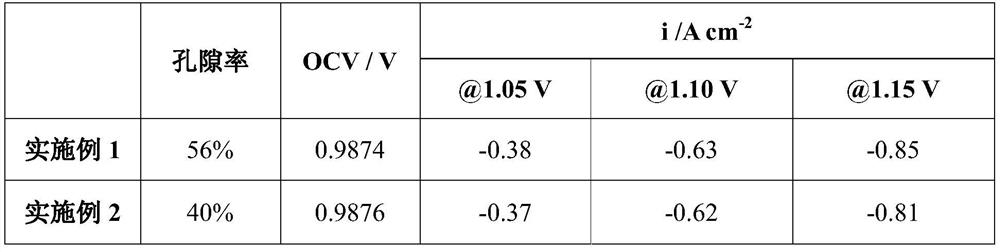

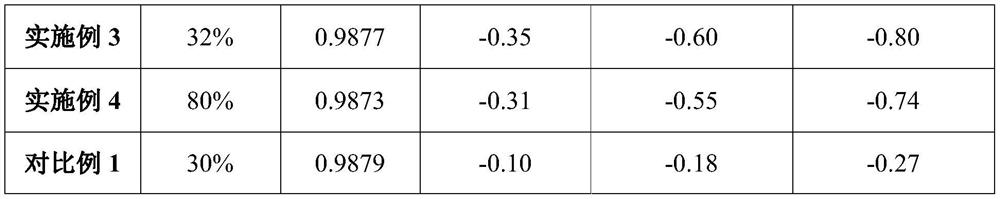

Examples

Embodiment 1

[0029] The preparation of a ternary composite anode for a solid oxide electrolytic cell comprises the following steps:

[0030] (1) 10~50nm Y 0.08 Zr 0.92 o 2 Ion conductive phase powder particles, CoO, MnO 2 , CeO 2 The oxide powders are mixed according to the stoichiometric ratio to ensure that the YSZ phase, Co 2.2 mn 0.8 o 4 Phase and Ce 0.8 co 0.1 mn 0.1 o 2 The mass ratio of the three phases is 50:40:10, and they are uniformly mixed by ball milling to obtain the electrode precursor mixed powder;

[0031] (2) Take 100g of the electrode precursor mixed powder obtained in step (1) and 15g of polymethyl isocyanate, 7.5g of polyethylene glycol 200 and 3g of polyoxyethylene sorbitan monooleate through ball milling under dry conditions, etc. The method is mixed evenly to obtain the electrode foaming slurry;

[0032] (3) The electrode foaming slurry obtained in step (2) is coated on a two-in-one half battery composed of a cathode and an electrolyte by a coating metho...

Embodiment 2

[0035] The preparation of a ternary composite anode for a solid oxide electrolytic cell comprises the following steps:

[0036] (1) 200~300nm Y 0.08 Zr 0.92 o 2 Ion conductive phase powder particles, CoO, MnO 2 , CeO 2 , SnO 2 The oxide powders are mixed according to the stoichiometric ratio to ensure that the YSZ phase, Co 2.2 mn 0.8 o 4 Phase and Ce 0.8 sn 0.2 o 2 The mass ratio of the three phases is 60:35:5, and they are uniformly mixed by ball milling to obtain the electrode precursor mixed powder;

[0037](2) Take 100g of the electrode precursor mixed powder obtained in step (1) and 3g of diphenylmethane diisocyanate, 9g of polypropylene glycol and 1.5g of polyoxyethylene sorbitan monooleate by ball milling under nitrogen protection conditions Mix evenly to obtain electrode foaming slurry;

[0038] (3) The electrode foaming slurry obtained in step (2) is prepared by tape casting under dry conditions on a two-in-one half battery composed of a cathode and an el...

Embodiment 3

[0041] The preparation of a ternary composite anode for a solid oxide electrolytic cell comprises the following steps:

[0042] (1) 50 ~ 100nm Gd 0.1 Ce 0.9 o 2 Ion conductive phase powder particles, CoO, Fe 2 o 3 , SnO 2 The oxide powders are mixed according to the stoichiometric ratio to ensure that the GDC phase, Co 2.2 Fe 0.8 o 4 phase and SnO 2 The mass ratio of the three phases is 50:45:5, and they are uniformly mixed by ball milling to obtain the electrode precursor mixed powder;

[0043] (2) Take 100g of the electrode precursor mixed powder obtained in step (1) and 10g of diphenylmethane diisocyanate, 2g of polypropylene glycol and 5g of polyoxyethylene sorbitan monooleate and mix them uniformly by ultrasonic method under dry conditions , to obtain electrode foaming slurry;

[0044] (3) Prepare the electrode foaming slurry obtained in step (2) by screen printing under dry conditions to form an anode on a two-in-one half battery composed of a cathode and an el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com