Industrial production method of galvanized IF steel with high salt spray corrosion resistance

A production method and salt-spray-resistant technology, applied in hot-dip galvanizing process, metal material coating process, manufacturing converters, etc., can solve problems such as not meeting standard requirements, optimize zinc layer thickness, and improve salt-spray corrosion resistance Ability to improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

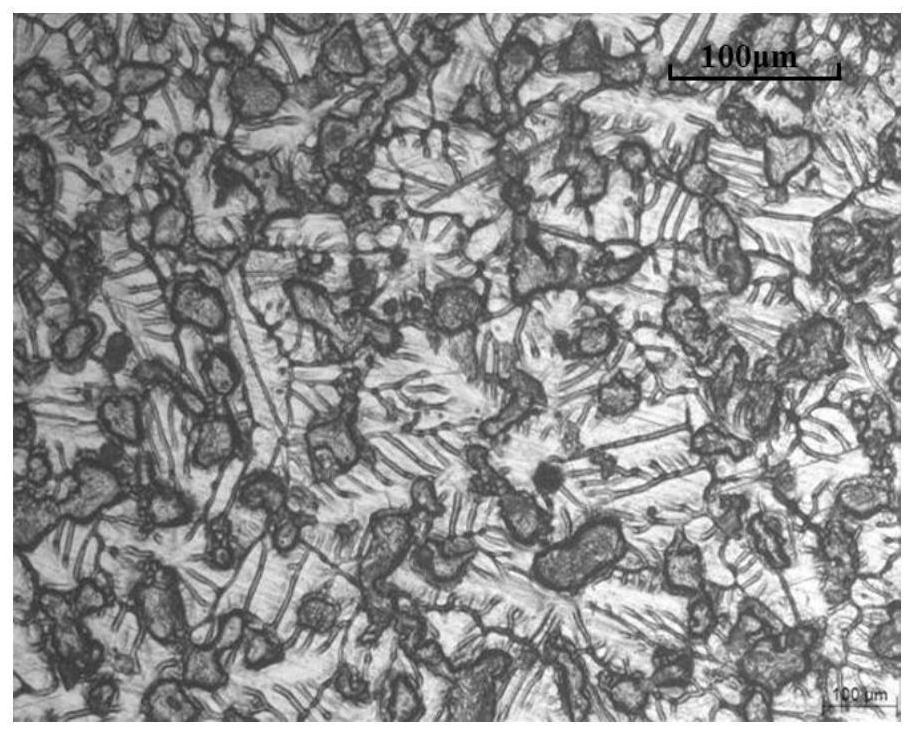

Image

Examples

Embodiment 1

[0038] Embodiment 1: The specific process after the specific research of the high salt spray corrosion resistance IF steel is as follows:

[0039] (1) Steelmaking process:

[0040] steelmaking control point Control range actual value Converter end point oxygen / ppm 400-500 400 RH oxygen blowing capacity / Nm 3

50-80 50 Oxygen at the end of RH decarburization / ppm 200-350 200 Aluminum loss / ppm 35-75 35 Constant pulling speed.m / min 0.8-1.6 0.8 Liquid level fluctuation control / mm ±5 ±5

[0041] (2) Hot rolling process:

[0042] hot rolling control point Control range actual value Dephosphorization water pressure / bar 190-210 190 In furnace time / min 180-196 180 Baking temperature / ℃ 1210-1250 1210 Convexity / μm 50-79 50 Cooling water pH between racks 7-9 7 Cooling water temperature / ℃ 20-32 20

[0043] (3) Galvanizing process:

[0044] Galvanized Control ...

Embodiment 2

[0046] Embodiment 2: The specific process after the specific research of the high salt spray corrosion resistance IF steel is as follows:

[0047] (1) Steelmaking process:

[0048] steelmaking control point Control range actual value Converter end point oxygen / ppm 400-500 465 RH oxygen blowing capacity / Nm 3

50-80 73 Oxygen at the end of RH decarburization / ppm 200-350 285 Aluminum loss / ppm 35-75 52 Constant pulling speed.m / min 0.8-1.6 1.1 Liquid level fluctuation control / mm ±5 ±5

[0049] (2) Hot rolling process:

[0050] hot rolling control point Control range actual value Dephosphorization water pressure / bar 190-210 201 In furnace time / min 180-196 186 Baking temperature / ℃ 1210-1250 1230 Convexity / μm 50-79 68 Cooling water pH between racks 7-9 8.2 Cooling water temperature / ℃ 20-32 20

[0051] (3) Galvanizing process:

[0052] Galvanized Contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com