A kind of titanium-magnesium-aluminum spinel-brown corundum composite sliding plate and production method thereof

A magnesia-aluminum spinel and production method technology, which is applied in the field of refractory materials, can solve the problems of the service life and safety factor of sliding bricks, high production costs and energy consumption, and structural damage of sliding bricks, etc., so as to shorten the production cycle and produce The effect of low cost and strong liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

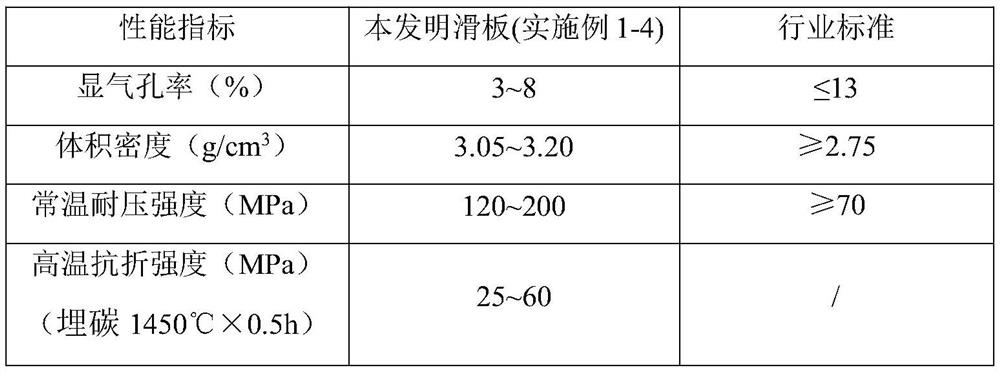

Examples

Embodiment 1

[0035] A titanium-magnesium-aluminum spinel-brown corundum composite sliding plate, in terms of weight percentage, the raw material composition is: 50% of brown corundum, 32% of magnesium-aluminum spinel, 8% of activated alumina fine powder, 5% of activated alumina Metal titanium, 5% metal aluminum, plus 3% thermosetting phenolic resin.

[0036] The weight ratio of different particle sizes is: particle size 1: particle size 2: particle size 3: particle size 5: particle size 6=15:25:10:18:14;

[0037] The model of activated alumina micropowder is RG4000; the model of binder phenolic resin is PF5323;

[0038] The production method of the composite skateboard includes the following steps:

[0039] (1) Weigh various raw materials according to the proportions, first put metal titanium, activated alumina micropowder, metal aluminum, and brown corundum and magnesia-aluminum spinel with particle size ≤ 0.2mm into the mixer, and mix for 15 to 30 minutes to obtain Mixed powder, spare;...

Embodiment 2

[0046] A titanium-magnesium-aluminum spinel-brown corundum composite sliding plate, in terms of weight percentage, the raw material composition is: 65% of brown corundum, 10% of magnesium-aluminum spinel, 7% of activated alumina fine powder, 8% of activated alumina Metal titanium, 10% metal aluminum, plus 4% thermosetting phenolic resin.

[0047] The weight ratio of different particle sizes is: particle size 1: particle size 2: particle size 3: particle size 6=20:25:20:10.

[0048] The production method of the composite slide plate is the same as that of Example 1, and the performance indicators of the obtained product are: apparent porosity 4.1%, bulk density 3.20g / cm 3 , Normal temperature compressive strength 168MPa, high temperature flexural strength (buried carbon 1450 ℃ × 0.5h) 52.8MPa.

Embodiment 3

[0050] A titanium-magnesium-aluminum spinel-brown corundum composite sliding plate, in terms of weight percentage, the raw material is composed of: 53% of brown corundum, 23% of magnesium-aluminum spinel, 4% of activated alumina fine powder, 12% of activated alumina Metal titanium, 8% metal aluminum, plus 4% thermosetting phenolic resin.

[0051] The weight ratio of different particle sizes is: particle size 1: particle size 2: particle size 3: particle size 4: particle size 5, particle size 6=18:20:15:5:10:8.

[0052] The production method of the composite slide plate is the same as that of Example 1, and the performance indicators of the obtained product are: apparent porosity 5.9%, bulk density 3.16g / cm 3 , Normal temperature compressive strength 142MPa, high temperature flexural strength (buried carbon 1450 ℃ × 0.5h) 43.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com