a lapo 4 : CE coated calcium strontium aluminum europium composite luminescent material and its preparation method and application

A luminescent material and coating technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of single rare-earth luminescent material, and achieve the effects of easy synthesis and simple method operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides the LaPO described in the technical scheme 4 The preparation method of Ce-coated calcium strontium aluminum europium composite luminescent material comprises the following steps:

[0034] Strontium nitrate, calcium nitrate, europium nitrate, aluminum nitrate, urea and water are mixed to obtain a mixed solution; the molar ratio of strontium nitrate, calcium nitrate, europium nitrate and aluminum nitrate is 0.49:0.49:0.02:2;

[0035] Combusting the mixed solution to obtain calcium strontium aluminum europium complex;

[0036] The calcium strontium aluminum europium complex, sodium phosphate, lanthanum nitrate, cerium nitrate and water are mixed for aqueous solution synthesis to obtain LaPO 4 : Ce coated calcium strontium aluminum europium composite luminescent material.

[0037] The invention mixes strontium nitrate, calcium nitrate, europium nitrate, aluminum nitrate, urea and water to obtain a mixed solution.

[0038] In the present inven...

Embodiment 1

[0049] 0.49mmol strontium carbonate (SrCO 3 ) was diluted with deionized water, stirred and mixed, and then added 0.98mmol concentrated nitric acid (97% in mass fraction), and the reaction was observed. When bubbles did not continue to appear, stop adding concentrated nitric acid, and heated and stirred at 50°C to obtain strontium nitrate (Sr(NO 3 ) 2 )solid;

[0050] to 0.49mmol Sr(NO 3 ) 2 , 0.49mmol Ca(NO 3 ) 2 4H 2 O, 0.02mmol Eu(NO 3 ) 3 ·6H 2 Add 10mL deionized water to O to obtain the first mixed solution;

[0051] to 2mmolAl(NO 3 ) 3 9H 2 Add 10mL deionized water in O and 2.2g urea, obtain the second mixed solution;

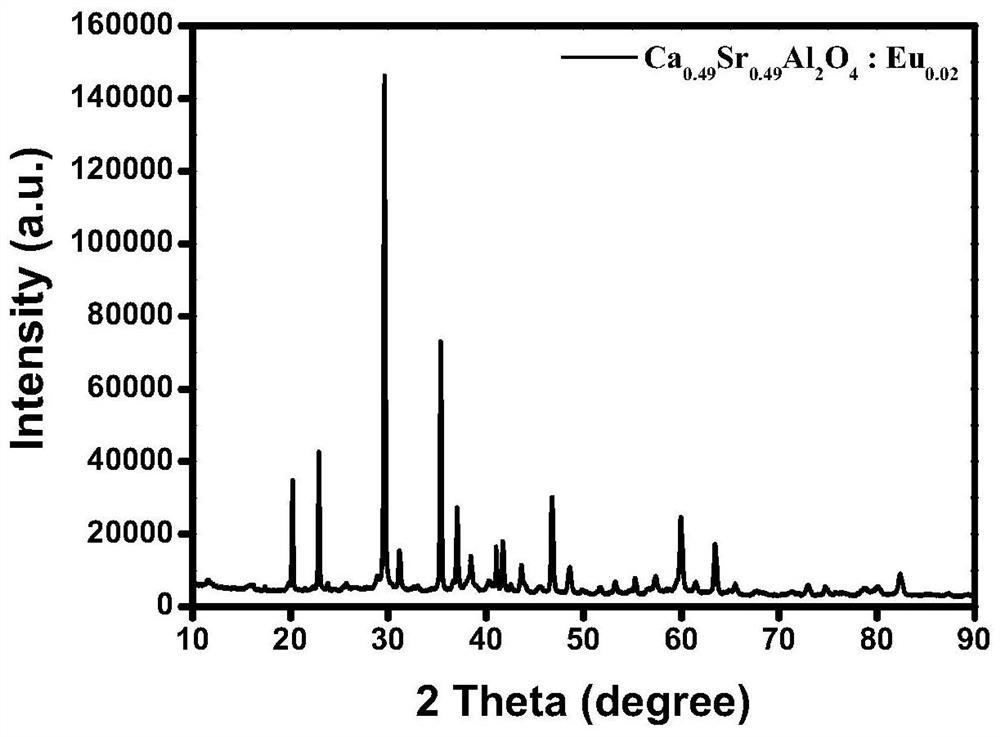

[0052] Add the first mixed solution to the second mixed solution, put the resulting solution into the crucible of the muffle furnace, preheat to 600°C, and heat for 2 minutes and 52 seconds to obtain the calcium strontium aluminum europium complex Ca 0.49 Sr 0.49 Al 2 o 4 : Eu 0.02 ;

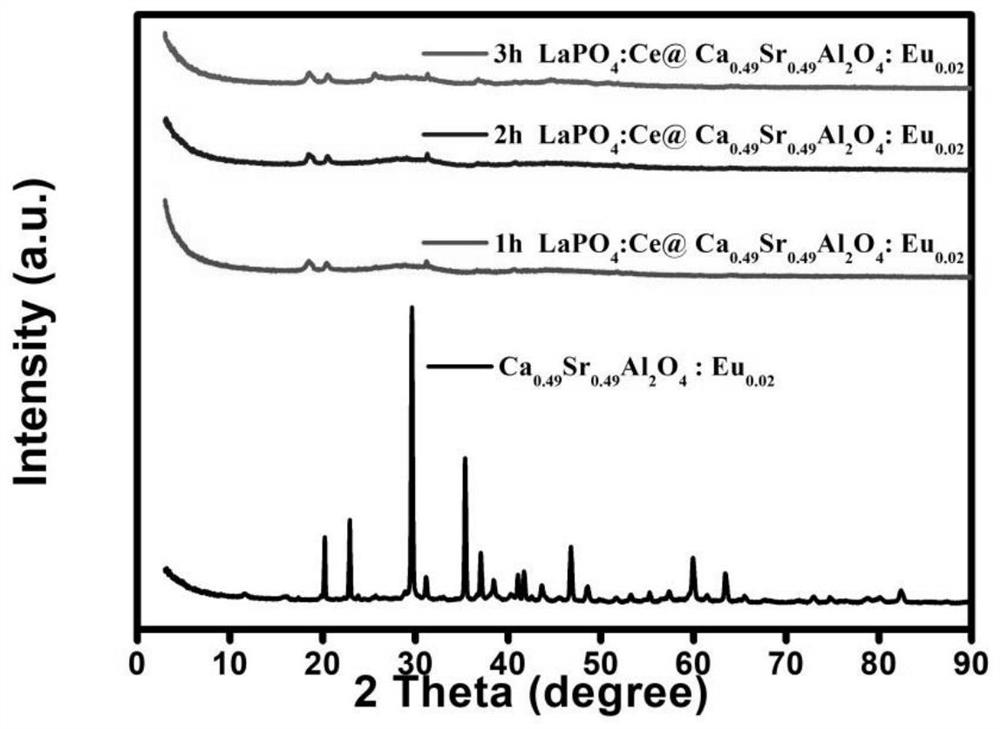

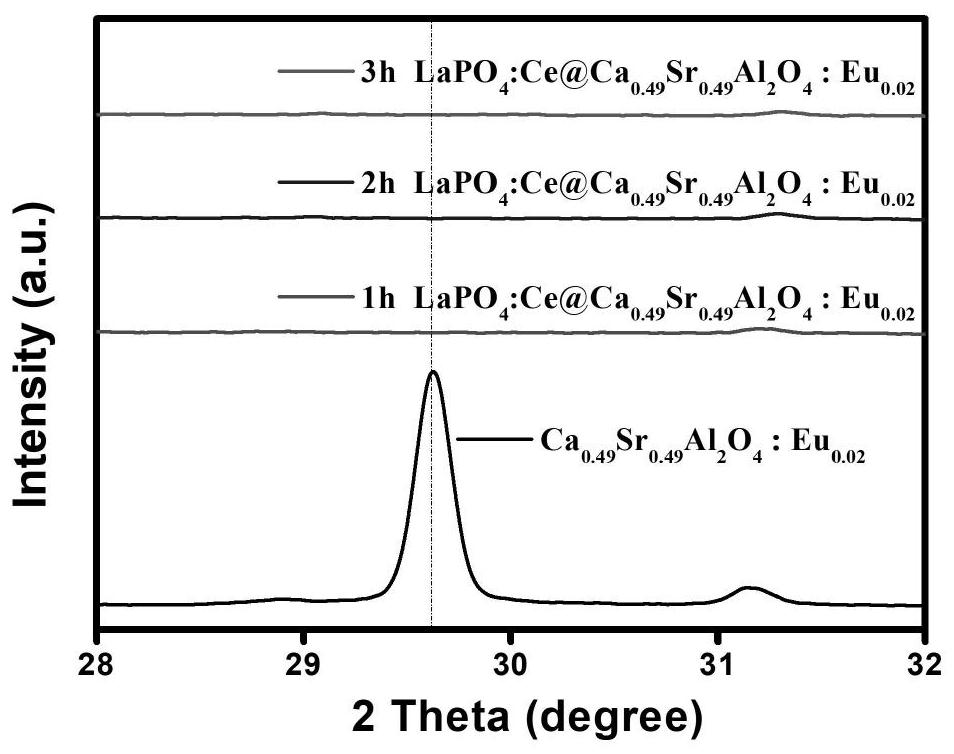

[0053] Mix 0.1 mmol of the calcium strontium alumi...

Embodiment 2

[0055] The only difference between this example and Example 1 is that the synthesis time of the aqueous solution is 2h, which is recorded as 2h LaPO 4 :Ce@Ca 0.49 Sr 0.49 Al 2 o 4 :Eu 0.02 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com