Preparation of novel flame retardant and application of novel flame retardant in flame-retardant adhesive

A flame retardant and adhesive technology, which is used in the preparation and application of polymer materials, can solve the problems of low cohesive energy, poor self-adhesion and mutual adhesion, and improve processing difficulty, and achieves high synthesis efficiency and adhesive strength. High, simple synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

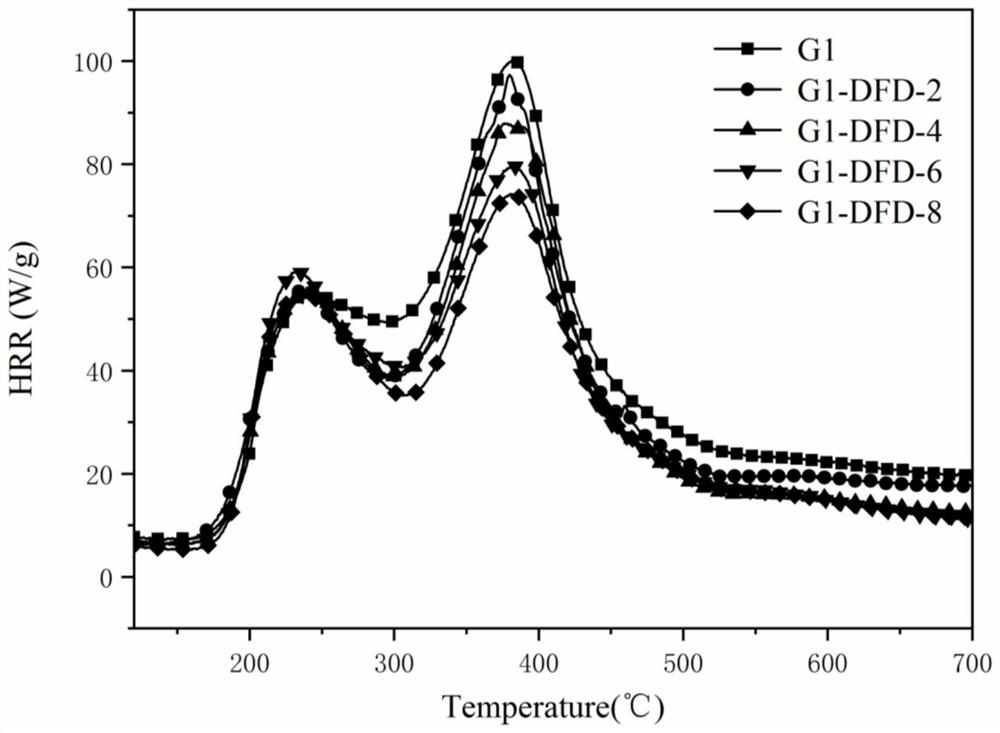

Image

Examples

Embodiment Construction

[0014] Technical scheme of the present invention is as follows:

[0015] A kind of preparation method of novel flame retardant, comprises steps as follows:

[0016] Under the condition of using a solvent, mix an organic compound containing an amino group, an organic compound containing a phosphorus-hydrogen bond, and an aldehyde (ketone) compound containing not less than one phenolic hydroxyl group in the molecular structure, and perform a one-step reaction to obtain a new type of inhibitor. Fuel. The reaction equation is as formula (1):

[0017]

[0018] In formula (1), R 2 to R 5 Can be a hydrogen atom or an organic group other than a hydrogen atom, R 1 , R 6 , R 7 It is an organic group that is not a hydrogen atom.

[0019] According to the present invention, preferably, the amino-containing organic compound is an organic compound containing no less than one amino group, including small molecular compounds containing amino groups, linear polymers containing amino ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com