Mask for deposition and method for manufacturing same

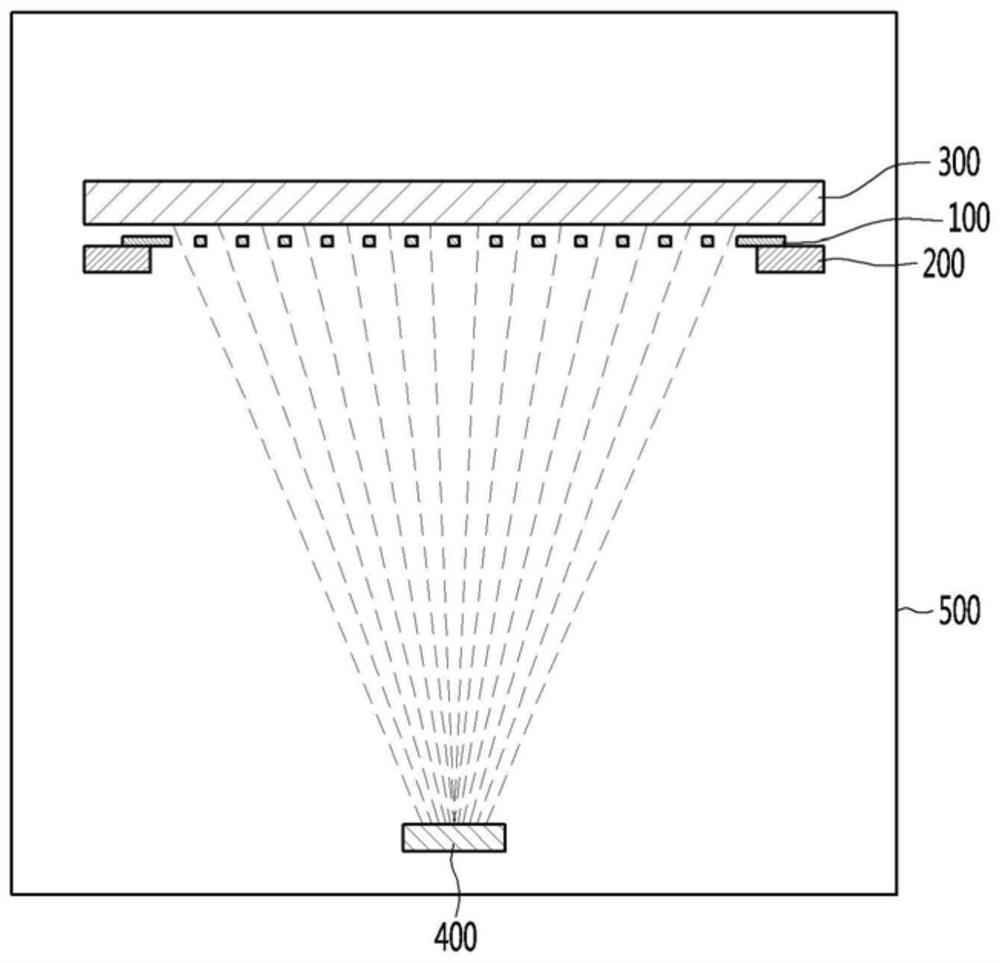

An evaporation and masking technology, which can be used in semiconductor/solid-state device manufacturing, organic light-emitting device manufacturing/processing, electrical components, etc., and can solve the problems of reducing the evaporation efficiency and evaporation quality of evaporation masks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

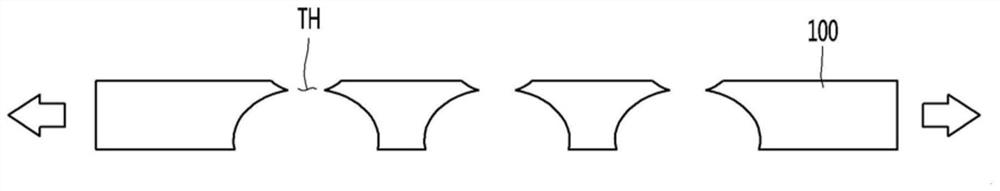

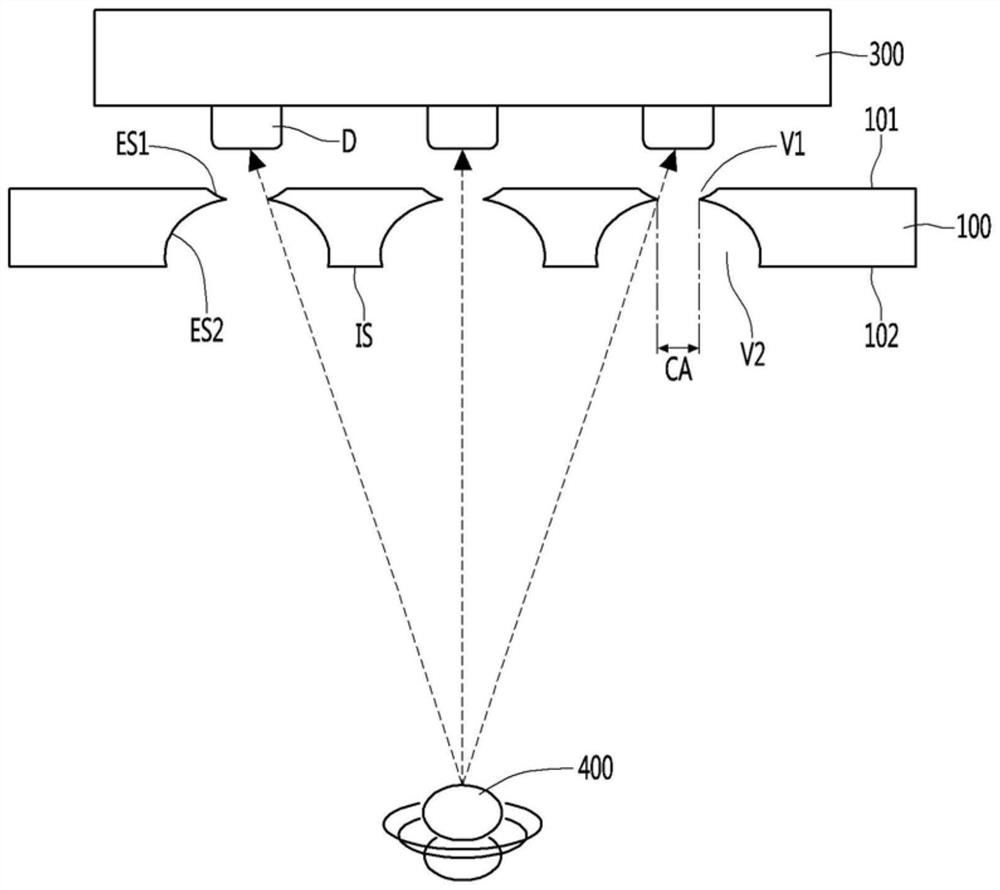

[0214] The method for preparing a mask for evaporation of a metal material used for OLED pixel evaporation can prepare the mask for evaporation of the embodiment, which includes the following steps: the first step is to prepare a base metal plate with a thickness of 20 μm to 30 μm; In the second step, a patterned photoresist layer is arranged on one surface of the base metal plate, and the opening of the photoresist layer is half-etched, thereby forming a pattern on one surface of the base metal plate. Grooves are formed on the base metal plate, and a patterned photoresist layer is arranged on the other surface of the base metal plate opposite to the one surface, and the opening of the photoresist layer is etched, thereby forming a through-holes connected by grooves on one surface of the base metal plate; and a third step of removing the photoresist layer, thereby forming a mask for evaporation including forming holes formed in the through-holes. A large surface hole on the on...

Embodiment 1

[0248] Small surface holes and large surface holes are formed in the effective part, and a plurality of dot-shaped first grooves are formed in the non-effective part. After preparing a mask for evaporation, after forming a plurality of second grooves in the non-evaporation part , Measure the TP (total pitch, total pitch) difference and straightness of the mask for evaporation.

[0249] Wherein, the area of the plurality of first grooves accounts for 45% of the total area of the non-effective portion.

[0250] In addition, the TP (total pitch, total pitch) difference is the difference between the lengths of the upper surface and the lower surface measured based on the direction in which the deposition mask is stretched, and the straightness is that the unbent When the position of the vapor deposition mask is assumed to be 0, the measured difference between the highest point of the upper and lower parts of the bend and 0.

Embodiment 2

[0252] Except that the shape of the first groove is striped, after preparing the mask for evaporation by the same method as in Example 1, after forming a plurality of second grooves in the non-evaporation part, measure the TP (total) of the mask for evaporation. pitch, total pitch) difference and straightness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com