Inductor and manufacturing method thereof

A technology of inductors and electrodes, applied in the field of inductors, can solve the problems of unfavorable large-scale production, increased equipment cost, high welding resistance, etc., and achieve the effects of avoiding high difficulty in coil winding, improving production efficiency, and strong ability to resist saturation current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

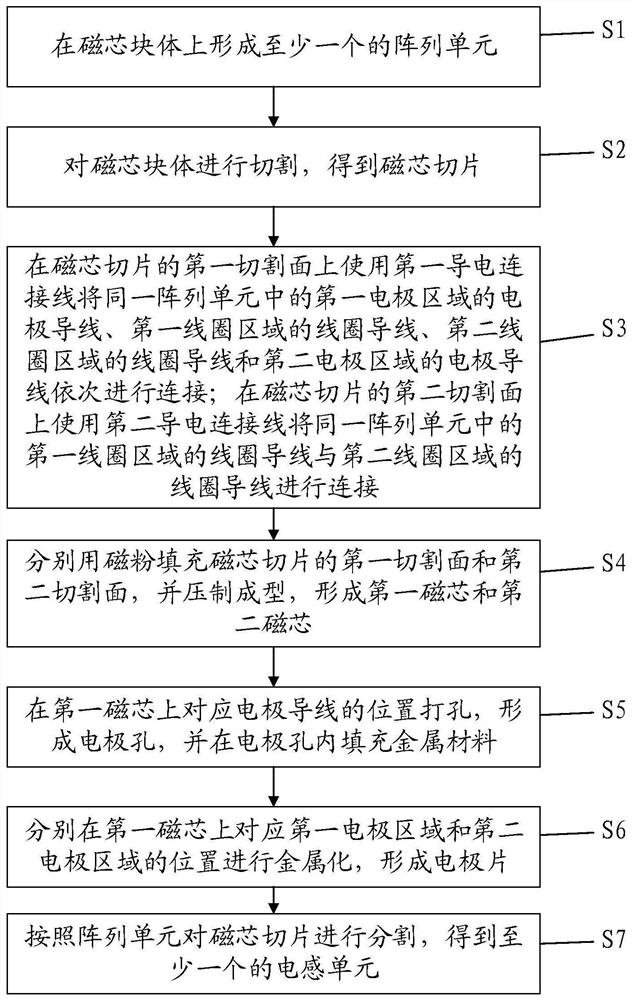

[0035] see figure 1 , a method for preparing an inductor, comprising:

[0036] (1) At least one array unit is formed on the magnetic core block, the array unit includes a first coil area and a second coil area that are oppositely arranged, and are respectively located on both sides of the first coil area and the second coil area The first electrode area and the second electrode area, the first coil area and the second coil area are respectively embedded with the same number of linearly arranged coil wires, and the first electrode area and the second electrode area are respectively embedded with an electrode wire, the coil wire and the electrode wire being parallel to each other;

[0037] (2) cutting the magnetic core block in a direction perpendicular to the length direction of the coil wire and the electrode wire to obtain a magnetic core slice;

[0038] (3) Use the first conductive connecting wire on the first cutting surface of the magnetic core slice to connect the elect...

Embodiment 1

[0059] Please refer to Figure 1-12 , Embodiment 1 of the present invention is: a preparation method of an inductor, which can be applied to the preparation of an integrally formed inductor, such as figure 1 shown, including the following steps:

[0060] S1: At least one array unit is formed on the magnetic core block.

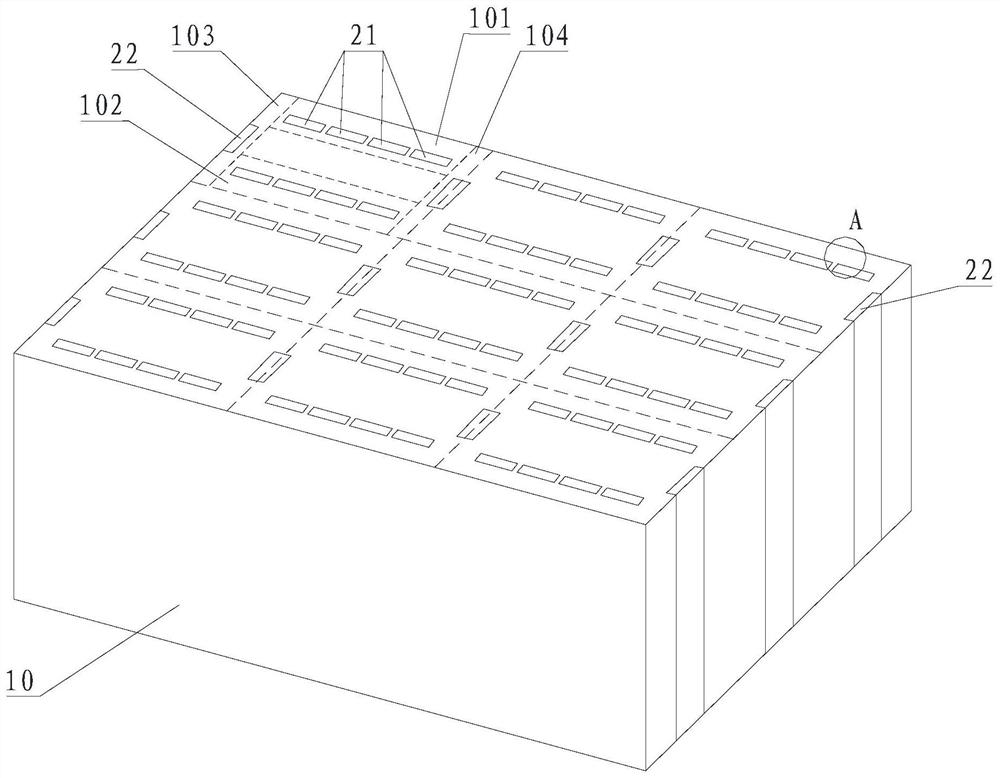

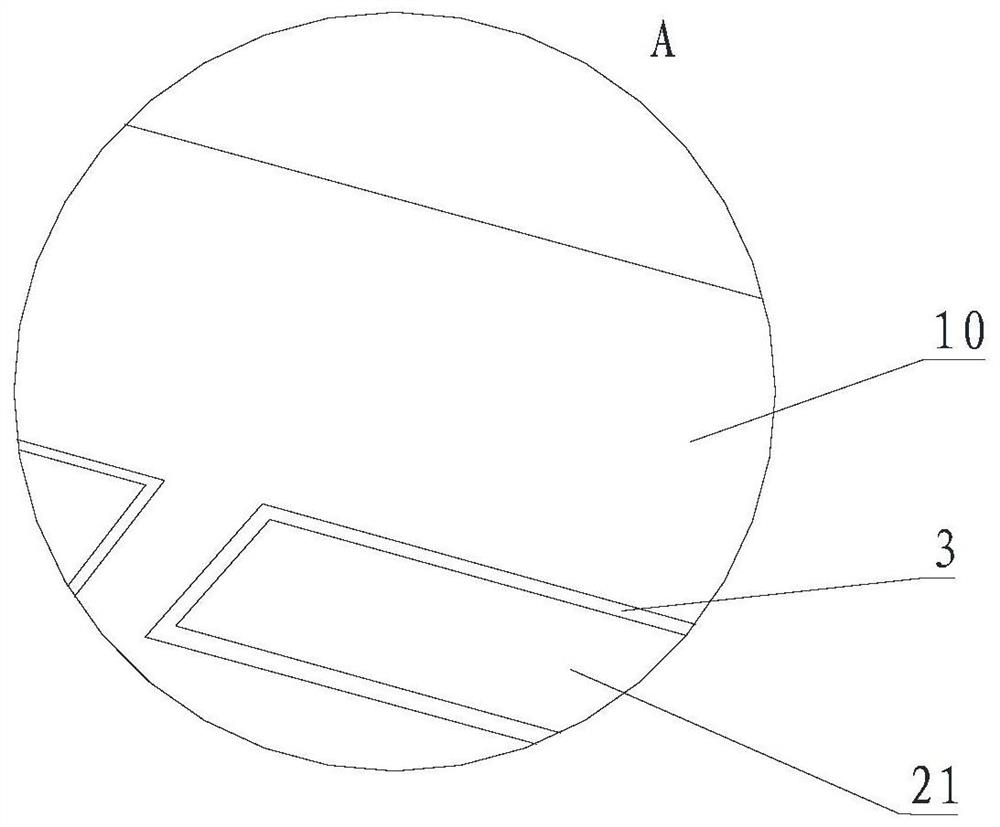

[0061] Such as figure 2 as shown, figure 2 Nine array units ( figure 2 9 parts of the same area divided by dotted lines), each array unit includes a first coil area 101 and a second coil area 102 that are oppositely arranged, and are respectively located in the first coil area 101 and the second coil area 102 The first electrode area 103 and the second electrode area 104 on both sides, the first coil area 101 and the second coil area 102 are respectively embedded with the same number of coil wires 21 arranged linearly, the first electrode area 103 and An electrode wire 22 is respectively embedded in the second electrode regions 104 , and the coil wire ...

Embodiment 2

[0085] This embodiment is a specific embodiment of the first embodiment.

[0086] In this embodiment, the material of the magnetic core block and the magnetic powder are FeSiCr alloy, the cross-sectional size of the coil wire is 0.2mm*0.04mm, the cross-sectional size of the electrode wire is 0.2mm*0.04mm, the material of the coil wire and the electrode wire They are all made of copper with an insulating layer on the surface; the area where the first conductive connecting wire and the second conductive connecting wire directly contact the coil wire and the electrode wire has no insulating layer, and other areas are attached with an insulating layer; the height of the magnetic core slice is 0.8 mm. The pressure of the pressing molding process used is 150MPa, and the temperature during pressing is 200°C. The metal material used to fill the electrode hole is a conductive paste. The conductive paste is a mixture of silver powder, copper powder and epoxy resin adhesive. The cross-se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com