Acoustic focusing inner cavity machining research method based on temperature gradient

A technology of inner cavity processing and temperature gradient, which is applied in ultrasonic/sonic/infrasonic transmission systems, transmission systems, electrical components, etc., and can solve the problems of narrow operating frequency band and mismatch of acoustic impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A research method based on temperature gradient acoustic focusing inner cavity processing provided by the present invention comprises the following steps:

[0033] Step 1. Based on the relationship between air sound velocity and temperature, design a new type of thermoacoustic combined metasurface phase control unit; control the sound wave velocity by changing the air temperature of the unit, and realize the sound wave transmission and reflection phase delay covering the 2π interval;

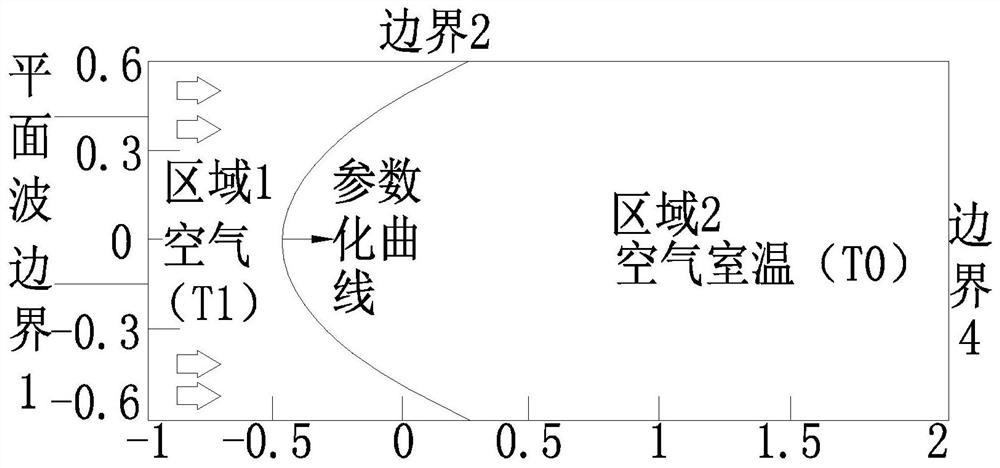

[0034] Step 2, model establishment and boundary condition setting; the model design is a rectangular area with a length of 100cm and a width of 80cm, the focal length is set to 30cm, the initial plane wave frequency is set to 40KHz, and the length of the metasurface in the transmission unit is 1cm; among them, the medium in the transmission unit is Air; the length of the metasurface is designed to be 1cm, and the available plane wave wavelength is about 8cm; it meets the size design requir...

Embodiment 2

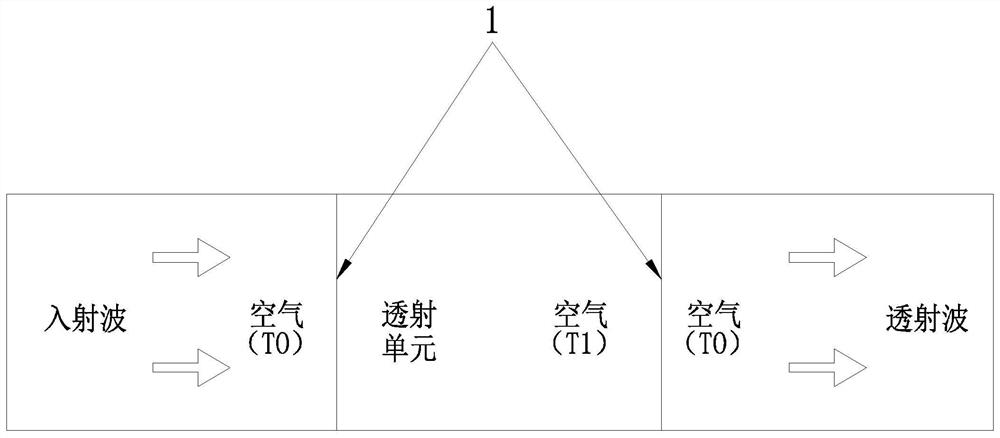

[0041] In this example, figure 2 Schematic diagram of the propagation model of a plane wave in a single transmission unit in the embodiment of the present invention, according to figure 2 The schematic diagram of the transmission acoustic wave focusing principle is shown to set appropriate boundary conditions and parameters. Then, according to the set parameters and boundary conditions, the influence of different sound velocities on the sound pressure distribution at the same frequency is obtained in the simulation software COMSOL, and the transmission elements are further combined to form an array to obtain the focusing effect of the transmitted sound wave.

[0042] The patent of the present invention utilizes discrete temperature combined with the idea of metasurface design, and through temperature regulation, the broadband focusing effect of sound waves can be realized.

[0043] Other content of this embodiment can refer to Embodiment 1.

Embodiment 3

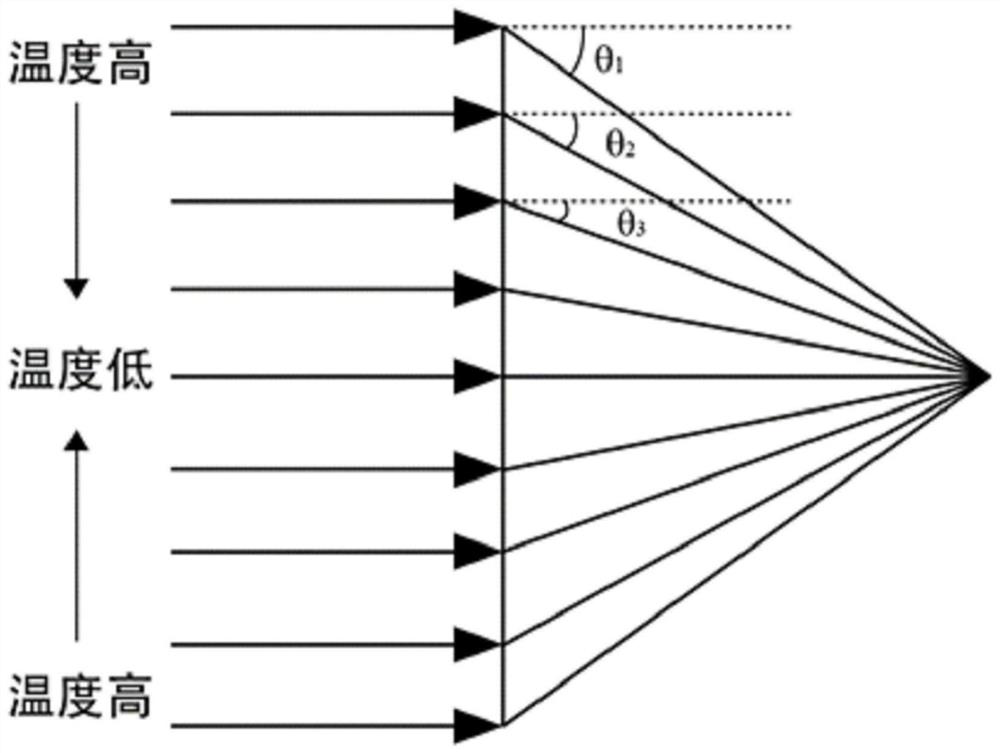

[0045] In this example, image 3 Schematic diagram of the principle of temperature-controlled acoustic wave focusing in the embodiment of the present invention, Figure 4 Schematic diagram of the longitudinal array distribution of the metasurface in the embodiment of the present invention; based on the propagation law and image 3 The schematic diagram of the principle of temperature-controlled sound wave focusing is shown in the rectangular area with a length of 100 cm and a width of 80 cm. Figure 4 The schematic diagram of the longitudinal array distribution of metasurface 1 is shown, and the focal length is designed to be 30cm; from figure 2 It can be seen that the two linear metasurfaces and the boundary form a rectangular transmission unit. Different constant temperatures are set in the transmission unit. The medium in the transmission unit is air. The sound velocity and air density are changed by temperature, thereby changing the acoustic impedance in the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com